Preparation method and application of modification-free super-hydrophobic copper layer

A water-copper and super-repellent technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of long standing time and poor stability of hydrophobic layer, and achieve the improvement of catalytic ability and equipment Simple, avoid the effect of composite electrodeposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In the first aspect of the present invention, a method for preparing a modification-free superhydrophobic copper layer is provided, comprising:

[0028] Pretreatment of the steel substrate;

[0029] Preparation of electrodeposition solution: mix copper salt solution and potassium sodium tartrate solution, and then add sodium hydroxide to obtain it;

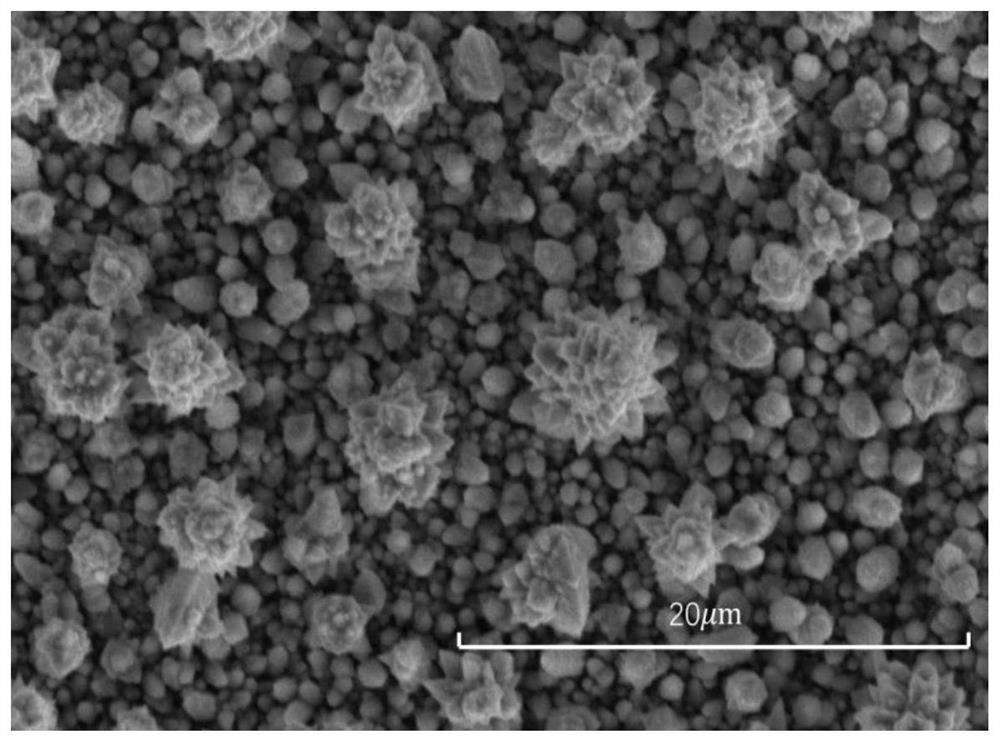

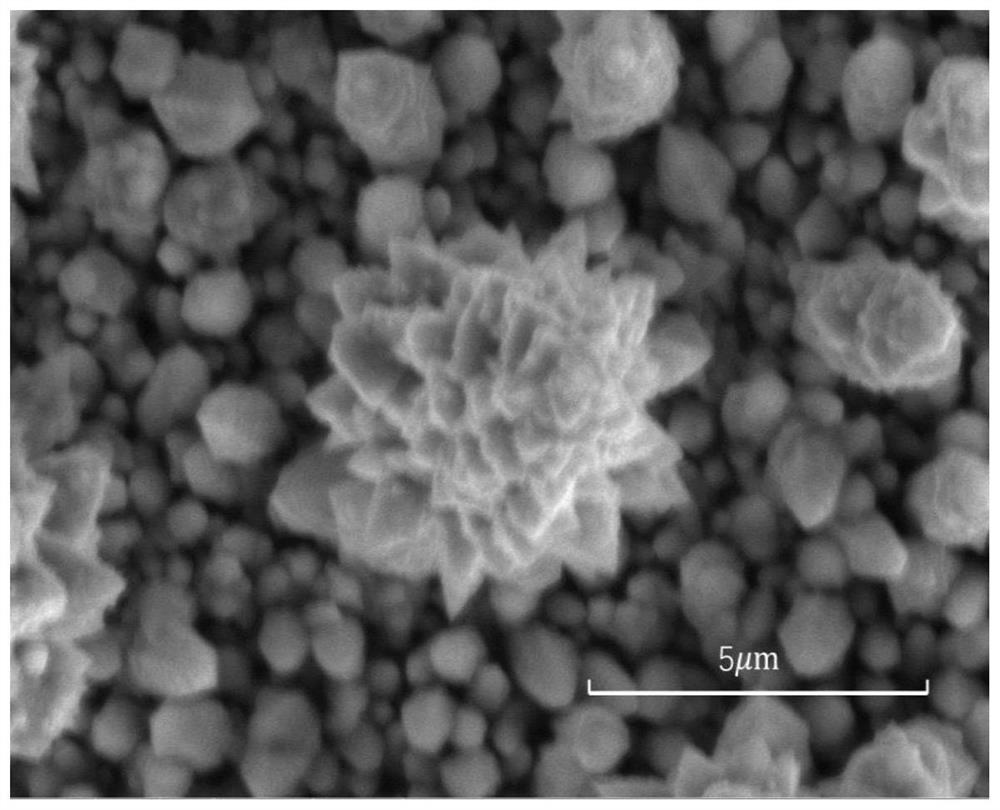

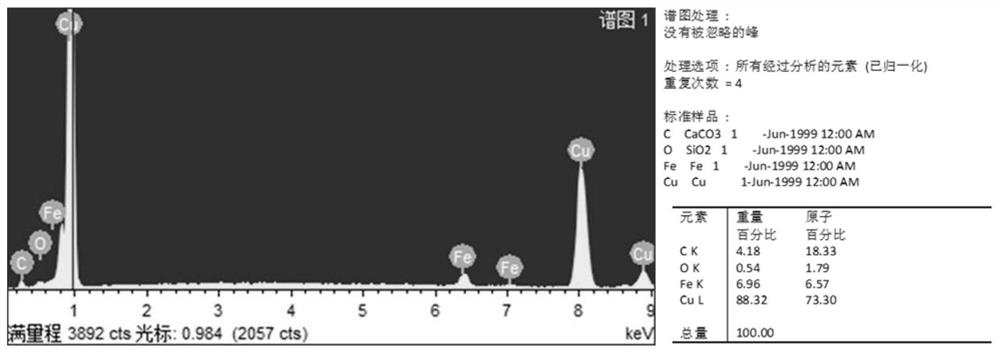

[0030] Electrodeposition process: use electrodeposition technology to deposit electrodeposition solution on the metal surface to form a biomimetic micro-nano structure copper layer; then place the metal at room temperature to obtain a modification-free super-hydrophobic copper layer.

[0031] In one or more embodiments of the present invention, the pre-treatment includes sanding, surface alkali cleaning and degreasing, and pickling activation treatment;

[0032] Preferably, the steel sample is smoothed with water sandpaper, and then the surface is subjected to alkali cleaning and degreasing and acid cleaning and activation...

Embodiment 1

[0054] The preparation method of superhydrophobic Cu electrodeposition layer in the present embodiment, comprises following several steps successively:

[0055] (1) Select X90 pipeline steel (20×50×3mm) as the base sample, pure copper plate (20×50×5mm) as the counter electrode sample, and polish the processed X90 pipeline steel and pure zinc sample with water sandpaper to 2000#, put the polished sample into absolute ethanol and ultrasonically clean it for 15 minutes to remove the grease and pollutants on the surface of the sample;

[0056] (2) Immerse the above-mentioned cleaned steel sample into a mixed aqueous solution containing 30g / L sodium hydroxide, 20g / L sodium carbonate, 20g / L sodium phosphate and 10g / L sodium silicate (60°C ) to remove oil by alkali washing for 15 minutes. 2 SO 4 Pickling and activation in aqueous solution (room temperature) for 15s, cleaning and drying after taking out, in order to improve the binding force between the composite electrodeposited la...

Embodiment 2

[0063] The preparation method of superhydrophobic Cu electrodeposition layer in the present embodiment, comprises following several steps successively:

[0064] (1) Select X90 pipeline steel (20×50×3mm) as the base sample, pure copper plate (20×50×5mm) as the counter electrode sample, and polish the processed X90 pipeline steel and pure zinc sample with water sandpaper to 2000#, put the polished sample into absolute ethanol and ultrasonically clean it for 15 minutes to remove the grease and pollutants on the surface of the sample;

[0065] (2) Immerse the above-mentioned cleaned steel sample into a mixed aqueous solution containing 40g / L sodium hydroxide, 25g / L sodium carbonate, 25g / L sodium phosphate and 15g / L sodium silicate (60°C ) to remove oil by alkali washing for 15 minutes. 2 SO 4 Pickling and activation in aqueous solution (room temperature) for 15s, cleaning and drying after taking out, in order to improve the binding force between the composite electrodeposited la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com