Controllable low-strength concrete containing desulfurization slag and steel slag

A desulfurization slag, low-strength technology that can be used in climate sustainability, sustainable waste treatment, solid waste management, etc., and can solve problems such as comprehensive utilization concerns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

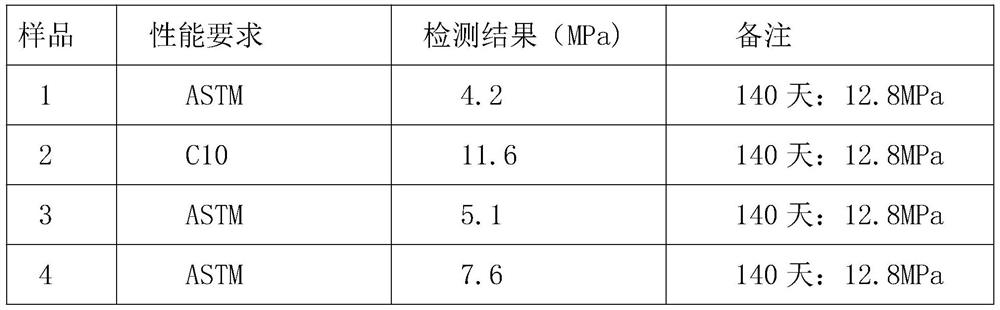

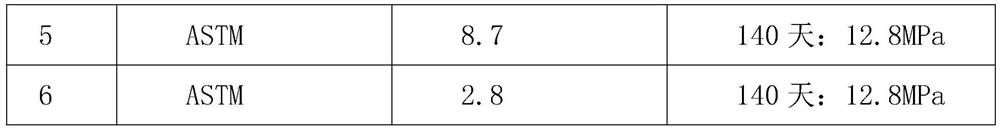

[0037] Example 1: Desulfurization slag plus steel slag to prepare CLSM (19 / 12 / 24)

[0038] Take each component according to the following weight: desulfurization slag 57, fly ash 10, water-quenched slag powder 14, steel slag 19, and the particle size of steel slag is controlled below 3mm;

[0039] Stir the desulfurization slag, fly ash, water-quenched slag powder and other powder materials first, then add water and mix well, then add steel slag and stir well, the water-powder ratio is 0.41, and the test tube fluidity (tube flow, ASTM D6103-04) is 15.5cm , make a 100*100*100mm test block, and moderately sprinkle water at room temperature for 28 days to get it.

[0040] In the early stage, due to the retarding effect of desulfurization slag, the strength developed slowly. After 28 days, it only reached 4.2MPa, after 90 days it reached 8.9MPa, and after 140 days it reached 12.8MPa. There is no swelling and bursting phenomenon after curing for 180 days at room temperature.

Embodiment 2

[0041] Example 2: Desulfurization slag plus steel slag to prepare CLSM (20 / 5 / 22)

[0042] Take each component according to the following weight: desulfurization slag 35, fly ash 12, water-quenched slag powder 12, steel slag 41;

[0043] Steel slag particle size screened below 0.6mm (standard sieve 30 mesh) is used;

[0044] Stir the desulfurization slag, fly ash, water-quenched slag powder and other powder materials first, then add water and mix well, then add steel slag and stir well, the water-powder ratio is 0.51, and the test tube flow is 16cm (ASTM standard is 15- 20cm), made into a 100*100*100mm test block, moderately watered and cured for 28 days at room temperature, that is. The 28-day strength is 11.6MPa.

[0045] After 14 days of curing, a high-temperature and high-pressure (205°C, 1.8MPa) steam curing test was carried out for 4 hours, and the sample remained intact, with only a few inconspicuous small blasts on the surface.

Embodiment 3

[0046] Example 3: Desulfurization slag plus steel slag tailings to prepare CLSM (20 / 6 / 9)

[0047]Take each component according to the following weight: desulfurization slag 38, fly ash 12, water-quenched slag powder 9, steel slag tailings (1) 41; steel slag tailings with a particle size of 2.36mm (standard sieve 8 mesh) or less are used;

[0048] Stir the desulfurization slag, fly ash, water-quenched slag powder and other powder materials first, then add water and mix well, then add steel slag tailings (1) and stir well, the water-powder ratio is 0.53, and the tube flow is 14.5cm , make a 100*100*100mm test block, and moderately sprinkle water at room temperature for 28 days to get it. The 28-day strength is 5.1Mpa, and the strength can meet the requirements for general roadbeds and building foundation cushions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com