A self-insulating biogas digester and its operating method

A methane digester and self-insulation technology, applied to biochemical equipment and methods, gas production bioreactors, biochemical instruments, etc., can solve the problems of increasing the workload of dehydration facilities, affecting the desulfurization effect of desulfurizers, increasing labor costs, etc., to achieve Reduce the impact of instability, improve the processing effect, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

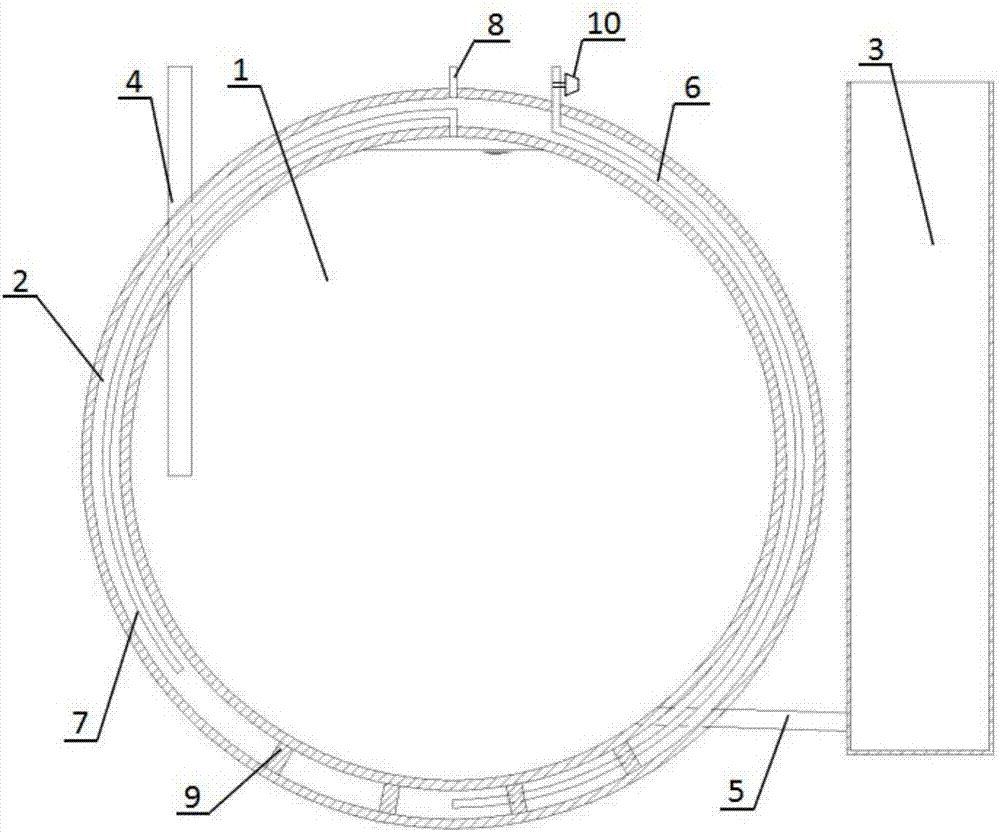

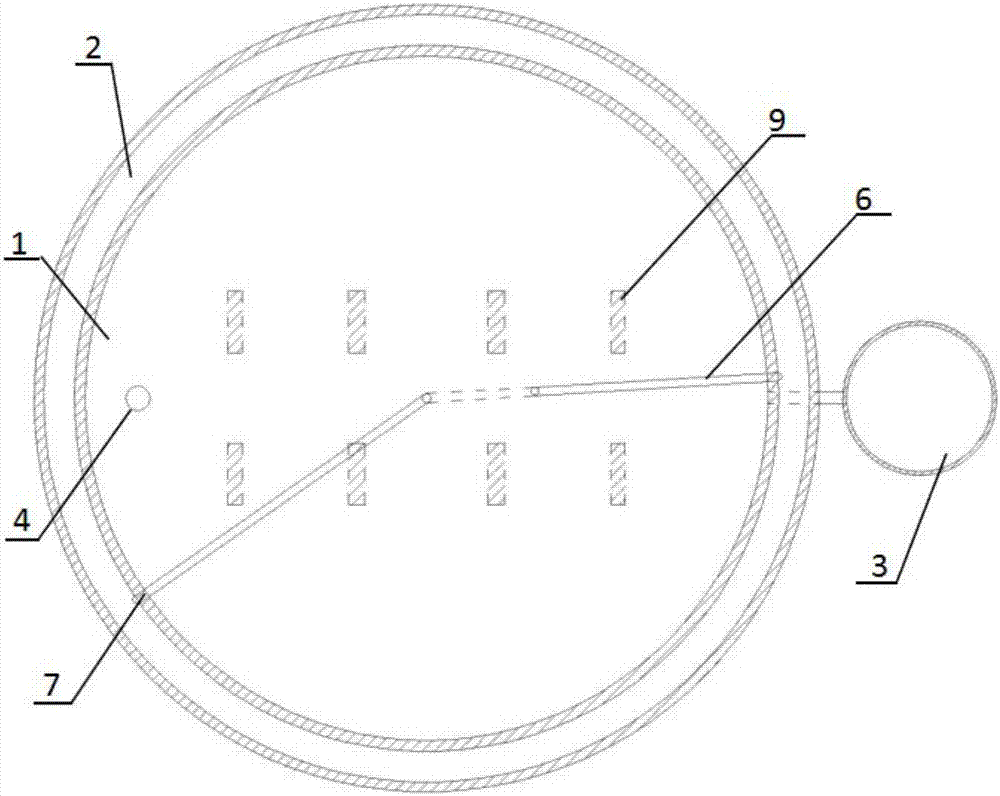

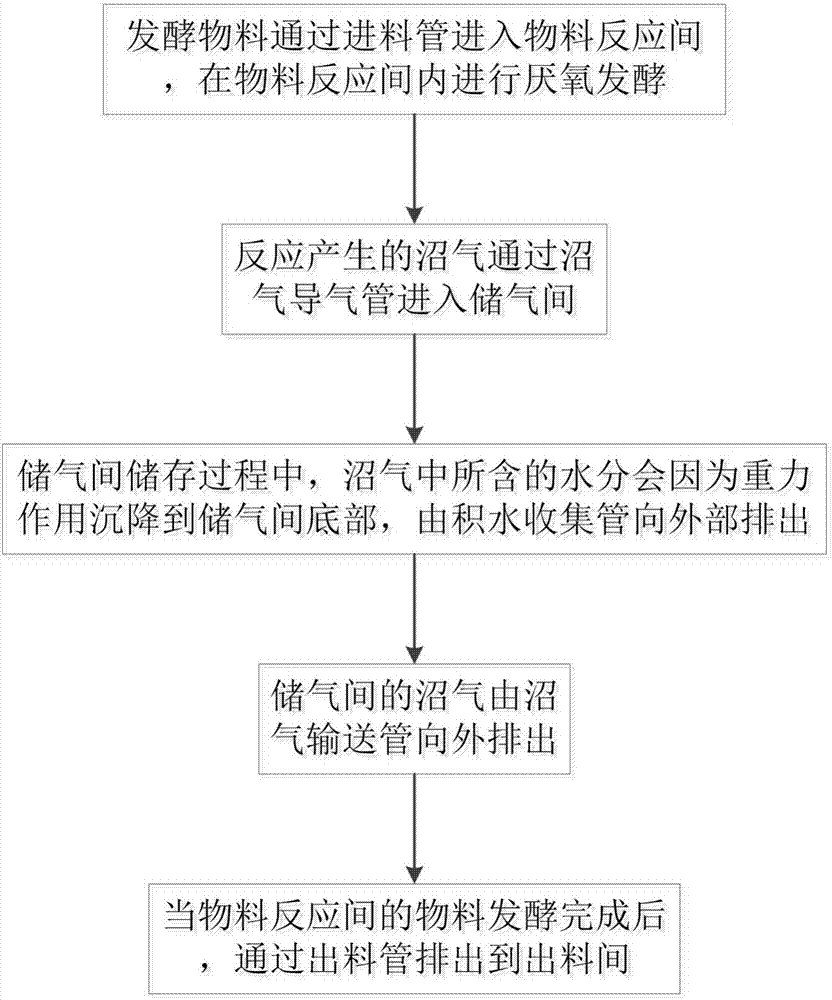

[0048] An optimal design is that the total effective volume of the self-heating biogas digester is 14m3, which is used by a single farmer. The sphere radius of the material reaction room 1 is 1.3m, the effective volume is 9.2m3, the sphere radius of the hollow gas storage interlayer 2 is 1.4m, the effective volume is 11.5m3, the discharge room 3 is cylindrical, the volume is 2m3, and glass fiber reinforced plastic is selected as the Materials.

[0049] The upper part of the material reaction room 1 is provided with an air guide pipe 7, and its outlet is at the lower part of the hollow gas storage interlayer 2, with a pipe diameter of 10 mm; a water collection pipe 6 with a pipe diameter of 10 mm is installed at the bottom of the hollow gas storage interlayer 2, and the hollow gas storage interlayer The top installation pipe diameter of 2 is the methane conveying pipe 8 of 10mm. The feed pipe 4 is vertically connected to the material reaction room 1, with a pipe diameter of 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com