Baking-free brick containing desulfurization slag and steel slag

A technology of desulfurization slag and unburned bricks, which is applied in the field of construction materials and can solve problems such as comprehensive utilization doubts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

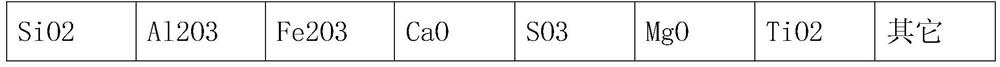

Method used

Image

Examples

Embodiment 1

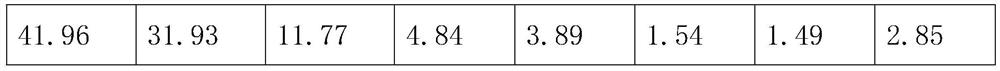

[0033] Example 1, desulfurization slag plus steel slag to prepare unfired bricks (19 / 10 / 26).

[0034] A 250-ton static brick machine is used to press 200x100x55mm Dutch bricks, and the average pressure is about 15-17kgf / cm 2 . The material formula takes each component according to the following weight: desulfurization slag 26, fly ash 3, 425 cement 13, water-quenched slag powder 16, steel slag 42, and the particle size of steel slag is controlled below 3mm;

[0035] Stir the desulfurization slag, fly ash, water-quenched slag powder and other powder materials evenly first, then add water and stir, then add steel slag and stir evenly, the water-powder ratio is 0.33. The stirring time should be moderate (the mixing time is too long, the humidity of the mixture will increase and form large clumps, which is not conducive to the formation of fabrics and pressed bricks), and it will be cured at room temperature with a humidity of 65-95% for 28 days.

[0036] Due to the retarding ef...

Embodiment 2

[0037] Example 2, desulfurization slag plus steel slag to prepare unburned bricks (19 / 12 / 9).

[0038] A 250-ton static brick machine is used to press 200x100x55mm Dutch bricks, and the average pressure is about 15-17kgf / cm 2 . The material formula takes each component according to the following weight: desulfurization slag 28, fly ash 3.5, 425 cement 7, water-quenched slag powder 18, steel slag 43.3, silicon-aluminum additive 0.2, and the particle size of steel slag is controlled below 3mm;

[0039] Stir the desulfurization slag, fly ash, water-quenched slag powder and other powder materials evenly first, then add water and stir evenly, then add steel slag and stir evenly, the water-powder ratio is 0.28. The stirring time should be moderate (the mixing time is too long, the humidity of the mixture will increase and form large clumps, which is not conducive to the formation of fabrics and pressed bricks), and it will be cured at room temperature with a humidity of 65-95% for 2...

Embodiment 3

[0041] Example 3, desulfurization slag plus steel slag to prepare unfired bricks (19 / 12 / 23).

[0042] A 250-ton static brick machine is used to press 200x100x55mm Dutch bricks, and the average pressure is about 15-17kgf / cm 2 . The material formula takes each component according to the following weight: desulfurization slag 27, fly ash 3.2, 425 cement 6.4, water-quenched slag powder 17, steel slag 46.4, and the particle size of steel slag is controlled below 3mm;

[0043] Stir the desulfurization slag, fly ash, water-quenched slag powder and other powder materials first, then add water and stir evenly. When adding water, spray evenly, and add the formula water in a short time, and finally add steel slag and stir evenly. The water-powder ratio is 0.24. The stirring time should be moderate (the mixing time is too long, the humidity of the mixture will increase and form large clumps, which is not conducive to the formation of fabrics and pressed bricks), and it will be cured at r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com