Reinforced concrete admixture and preparation method thereof

A concrete and reinforced technology, applied in the field of building materials, can solve the problems of concrete workability and adverse effects of early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

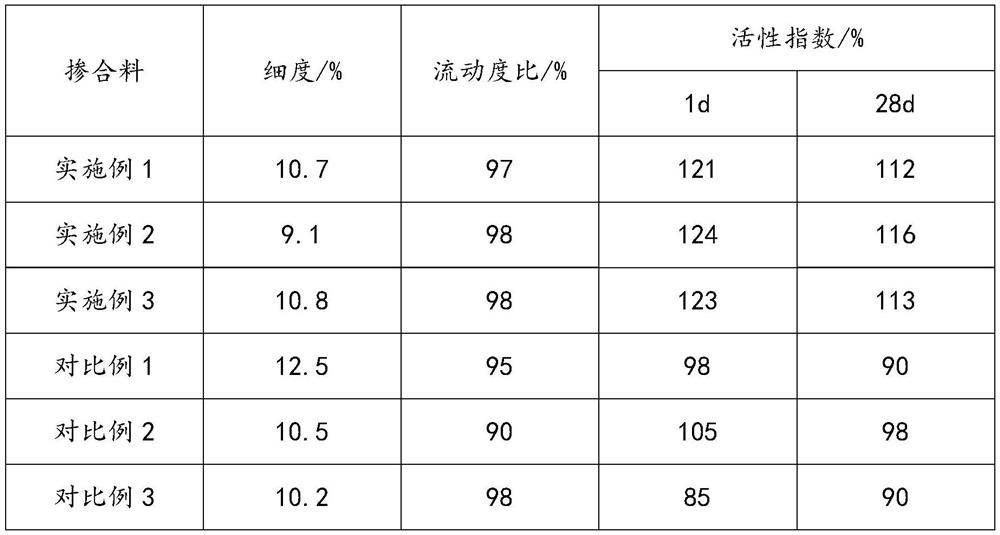

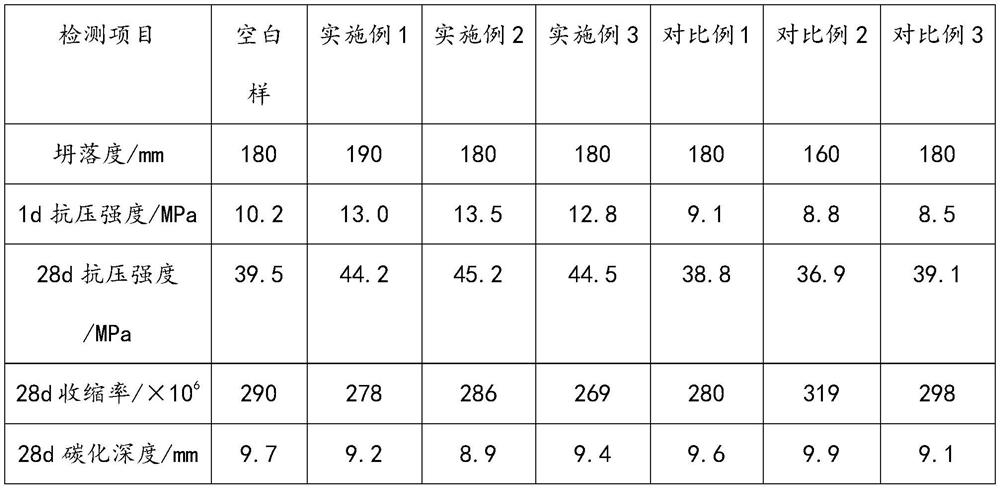

Examples

Embodiment 1

[0033] (1) Preparation of grinding aid: 50.00g of triethanolamine, 50.00g of triethylenepropanolamine, 60.00g of molasses, urea solution (16.00g of urea, 84.00g of water), glycerin (2.00g of glycerin, 98.00g of water), drip Add it into 640.00g of water for reaction, raise the temperature to 50°C for reaction, and add it dropwise for 1 hour to obtain a grinding aid.

[0034] (2) Preparation of modified marble-slag powder: Add 3500g of waste marble stone powder, 1500g of granulated blast furnace slag powder and 1.00g of grinding aid into a ball mill, grind for 20 minutes, and keep the process at 60°C to obtain modified marble-slag powder ;The specific surface area is 1100m 2 / kg, the water demand ratio is 82%, and the 28d strength activity index is 95%.

[0035] (3) Preparation of early strength agent: Mix 100.00 g of sodium sulfate, 2.00 g of carboxymethyl cellulose, 2.00 g of hydroxyethyl cellulose, and 2.00 g of sodium dodecylsulfonate to prepare an early strength agent.

...

Embodiment 2

[0042] (1) Grinding aid preparation: N, N dimethylethanolamine 60.00g, diethanol monoisopropanolamine 40.00g, molasses 70.00g, urea solution (urea 20.00g, water 80.00g), glycerin (glycerin 2.50g , water 97.50g), added dropwise into 630.00g water to react, heated up to 45°C for reaction, and the dropwise addition time was 0.75h to obtain a grinding aid.

[0043] (2) Preparation of modified marble-slag powder: Add 3500g of waste marble stone powder, 1500g of granulated blast furnace slag powder and 1.20g of grinding aid into a ball mill, grind for 25 minutes, and keep the process at 60°C to obtain modified marble-slag powder ;The specific surface area is 1150m 2 / kg, the water demand ratio is 83%, and the 28d strength activity index is 98%.

[0044] (3) Preparation of early strength agent: 100.00 g of calcium sulfate, 1.00 g of carboxymethyl cellulose, 1.00 g of hydroxypropyl cellulose, and 1.00 g of triterpene saponins were mixed to prepare an early strength agent.

[0045] (4)...

Embodiment 3

[0051] (1) Grinding aid preparation: 60.00g of N,N-dibenzylethanolamine, 20.00g of diethanolamine, 20.00g of diethanol monoisopropanolamine, 70.00g of molasses, urea solution (20.00g of urea, 80.00g of water) 1. Glycerin (3.50 g of glycerol, 96.50 g of water), was added dropwise into 630.00 g of water for reaction, and the temperature was raised to 45° C. for reaction, and the dropwise addition time was 1.5 h to obtain a grinding aid.

[0052] (2) Preparation of modified marble-slag powder: Add 3500g of waste marble stone powder, 1500g of granulated blast furnace slag powder and 1.50g of grinding aid into a ball mill, grind for 25 minutes, and keep the process at 60°C to obtain modified marble-slag powder ; The specific surface area is 1180m 2 / kg, the water demand ratio is 80%, and the 28d strength activity index is 93%.

[0053] (3) Preparation of early strength agent: 100.00 g of sodium sulfate, 1.60 g of carboxymethyl cellulose, 1.40 g of hydroxyethyl methyl cellulose, 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com