Cargo size self-adaptive channel type plasma disinfecting and killing system

A plasma and self-adaptive technology, applied in the field of sterilization, can solve the problems of difficult sealing, odor, and weak sterilization effect, and achieve the effects of reducing operating power and operating costs, reducing exhaust gas, and improving efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

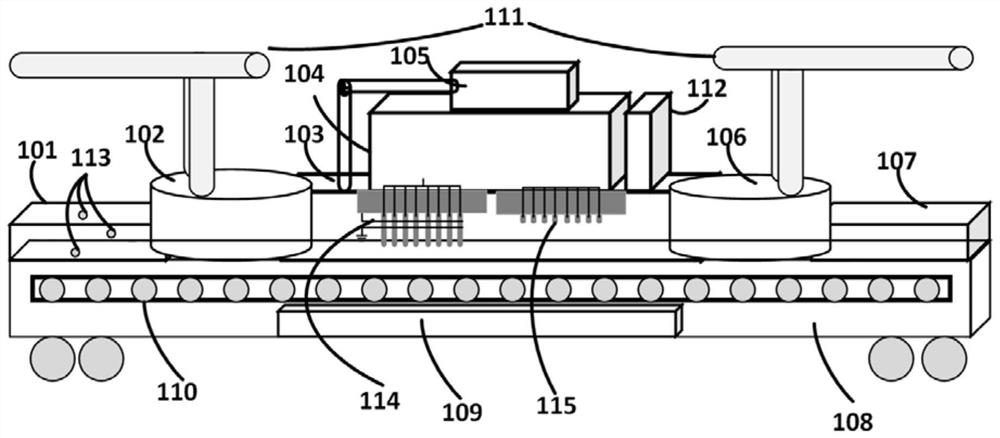

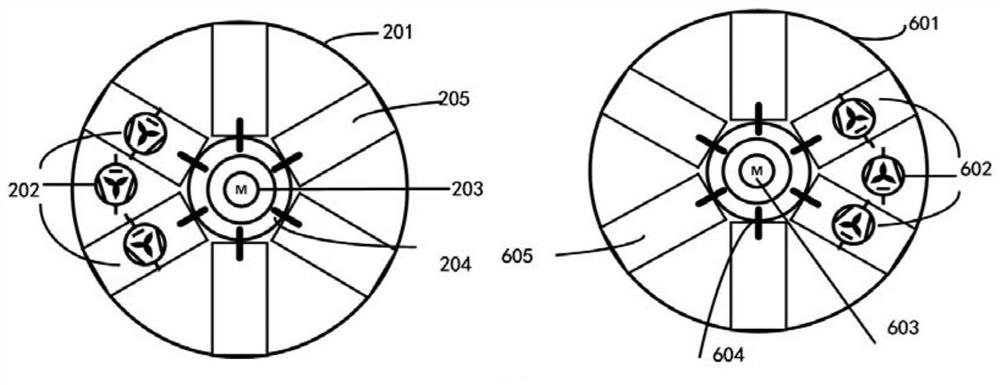

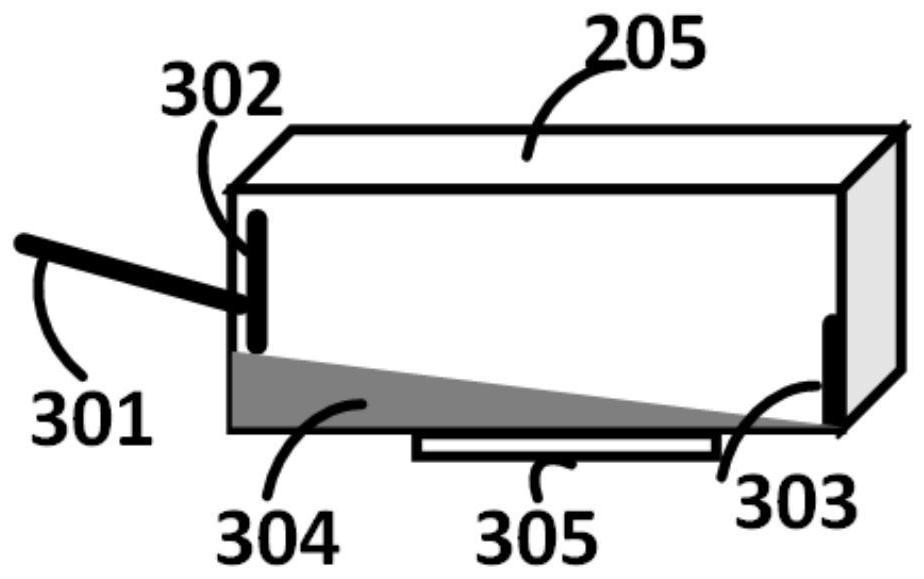

[0052] like Figure 1-3 As shown, an adaptive cargo size channel type plasma disinfecting system mainly includes: a cargo inlet 101, a cargo inlet rotary pretreatment turntable 102, a disinfecting main channel 103, a high voltage power supply 104, a protective gas unit 105, and a cargo outlet Rotating post-processing turntable 106, delivery outlet 107, waste water recycling unit 109, disinfecting channel support body 108, cargo delivery mechanism 110, waste gas treatment unit 111, dehumidification unit 112, inlet size identification unit 113, plasma injection array 114 , spray unit 115;

[0053] The disinfecting main channel 103 is located above the supporting body 108 of the disinfecting channel, and the main channel 103 is fixedly connected with the supporting body 108 of the disinfecting channel; 101 is connected with the shipping outlet 107, and the incoming goods entrance 101 is provided with an incoming goods entrance size identification unit 113; the inside of the main pa...

Embodiment 2

[0063] like Figure 4 As shown, an adaptive cargo size channel type plasma disinfecting system mainly includes: incoming goods entrance 101, disinfecting main channel 103, high voltage power supply 104, protective gas unit 105, shipping outlet 107, waste water recovery unit 109, disinfection disinfecting channel support body 108, cargo conveying mechanism 110, exhaust gas treatment unit 111, dehumidification unit 112, cargo inlet size identification unit 113, plasma injection array 114, spray unit 115;

[0064] The disinfecting main channel 103 is located above the supporting body 108 of the disinfecting channel, and the main channel 103 is fixedly connected with the supporting body 108 of the disinfecting channel; 101 is connected with the shipping outlet 107, and the incoming goods entrance 101 is provided with an incoming goods entrance size identification unit 113; the inside of the main passage for disinfecting 103 is provided with a plasma injection array 114, a spray unit...

Embodiment 3

[0073] This embodiment takes the surface sterilization of standard packing boxes as an example, and adopts the self-adaptive cargo size channel type plasma sterilization system described in Embodiment 1. The specific working process is: the device rotates and preprocesses the inlet through an external power supply The turntable 102, the size identification unit 113 of the inlet port, the plasma array support, the high voltage power supply 104, the shielding gas unit 105, the spray unit 115, the cargo conveying mechanism 110, and the rotary post-processing turntable 106 of the outlet port provide electric energy. The goods conveying mechanism 110 is started, the spray unit 115 is started, the high-voltage power supply 104 is started, the shielding gas unit 105 is started, the inlet port rotates the pretreatment carousel exhaust unit 202, and the outlet port rotates the post-treatment carousel exhaust unit 602. The goods are sent into the goods inlet 101 , and the size is manuall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com