A kind of oral denture material and preparation method thereof

A denture and oral cavity technology, applied in the field of medical material preparation, can solve the problems of reducing elastic modulus and flexural strength, composite modification antagonism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

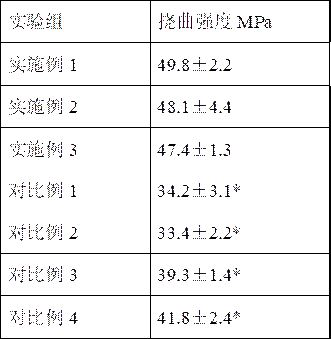

Examples

Embodiment 1

[0021] An oral denture material, the oral denture material is made of polymethyl methacrylate dispersion modified zirconia and aluminum oxide; the modified zirconia and aluminum oxide are zirconia modified by silane coupling agent and alumina; the silane coupling agent is a mixture of γ-glycidyloxypropyltrimethoxysilane and N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane in a mass ratio of 1:1 mixture.

[0022] The preparation method of the above-mentioned oral denture material is carried out according to the following steps:

[0023] (1) Add the silane coupling agent into the absolute ethanol solution, configure the silane coupling agent solution with a mass concentration of 2-5%, add zirconia, alumina and hydrochloric acid aqueous solution with a mass concentration of 3-8%; The addition of zirconia accounts for 3-5% of the mass of the silane coupling agent solution; the addition of alumina accounts for 3-5% of the mass of the silane coupling agent solution; the addition of a...

Embodiment 2

[0028] An oral denture material, the oral denture material is made of polymethyl methacrylate dispersion modified zirconia and aluminum oxide; the modified zirconia and aluminum oxide are zirconia modified by silane coupling agent and alumina; the silane coupling agent is a mixture of γ-glycidyloxypropyltrimethoxysilane and N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane in a mass ratio of 1:1 mixture.

[0029] The preparation method of the above-mentioned oral denture material is carried out according to the following steps:

[0030] (1) Add the silane coupling agent into the absolute ethanol solution, configure the silane coupling agent solution with a mass concentration of 2-5%, add zirconia, alumina and hydrochloric acid aqueous solution with a mass concentration of 3-8%; The addition of zirconia accounts for 3-5% of the mass of the silane coupling agent solution; the addition of alumina accounts for 3-5% of the mass of the silane coupling agent solution; the addition of a...

Embodiment 3

[0035] An oral denture material, the oral denture material is made of polymethyl methacrylate dispersion modified zirconia and aluminum oxide; the modified zirconia and aluminum oxide are zirconia modified by silane coupling agent and alumina; the silane coupling agent is a mixture of γ-glycidyloxypropyltrimethoxysilane and N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane in a mass ratio of 1:1 mixture.

[0036] The preparation method of the above-mentioned oral denture material is carried out according to the following steps:

[0037] (1) Add the silane coupling agent into the absolute ethanol solution, configure the silane coupling agent solution with a mass concentration of 2-5%, add zirconia, alumina and hydrochloric acid aqueous solution with a mass concentration of 3-8%; The addition of zirconia accounts for 3-5% of the mass of the silane coupling agent solution; the addition of alumina accounts for 3-5% of the mass of the silane coupling agent solution; the addition of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com