High-precision hanger for expansion valve oxidation line and locating mechanism thereof

A positioning mechanism and high-precision technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of inability to meet the requirements of automatic loading and unloading of robots, inability to realize automatic loading and unloading, and high dependence on manual proficiency, so as to shorten loading and unloading. time, meet the requirements of manipulator loading and unloading, and realize the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

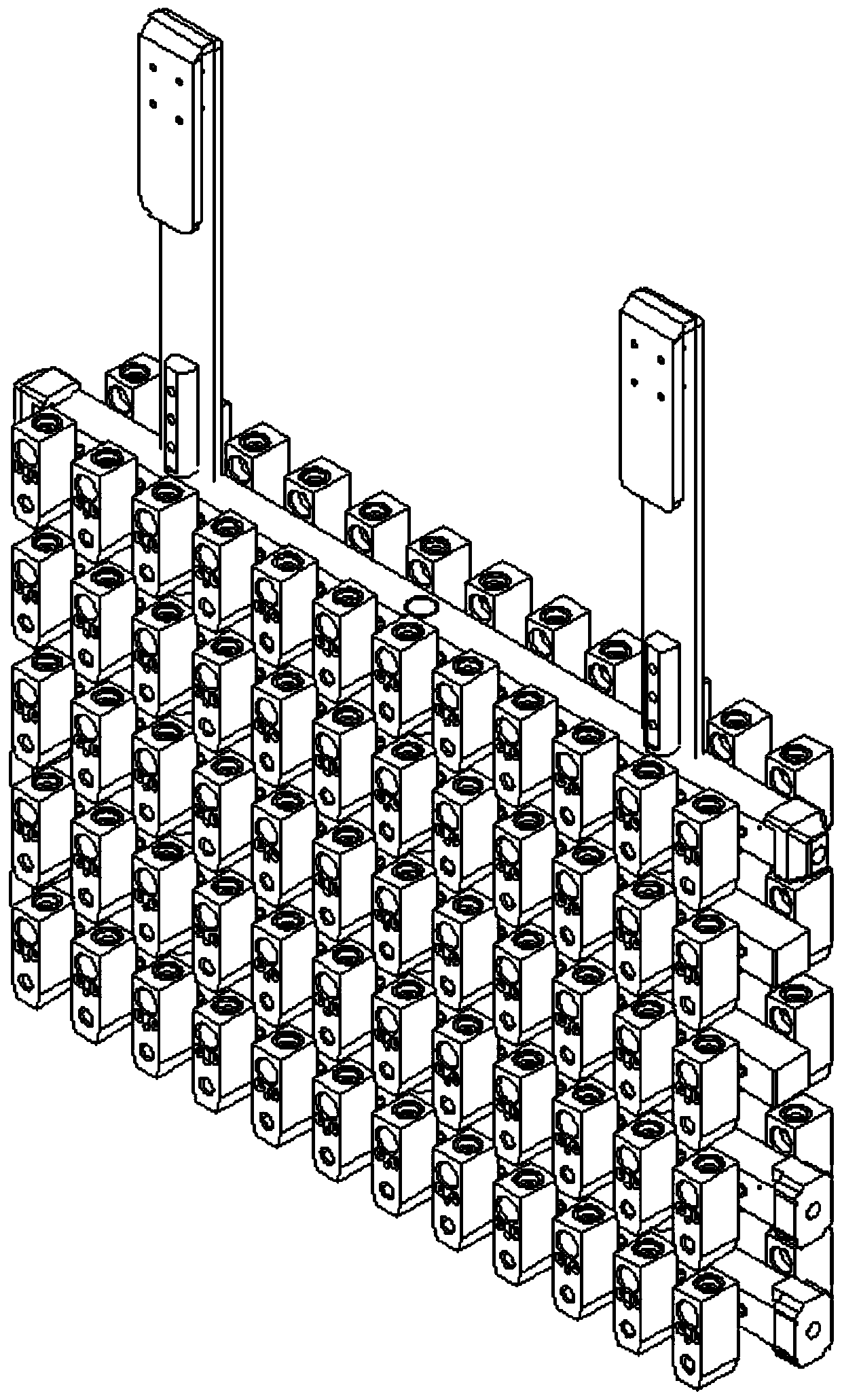

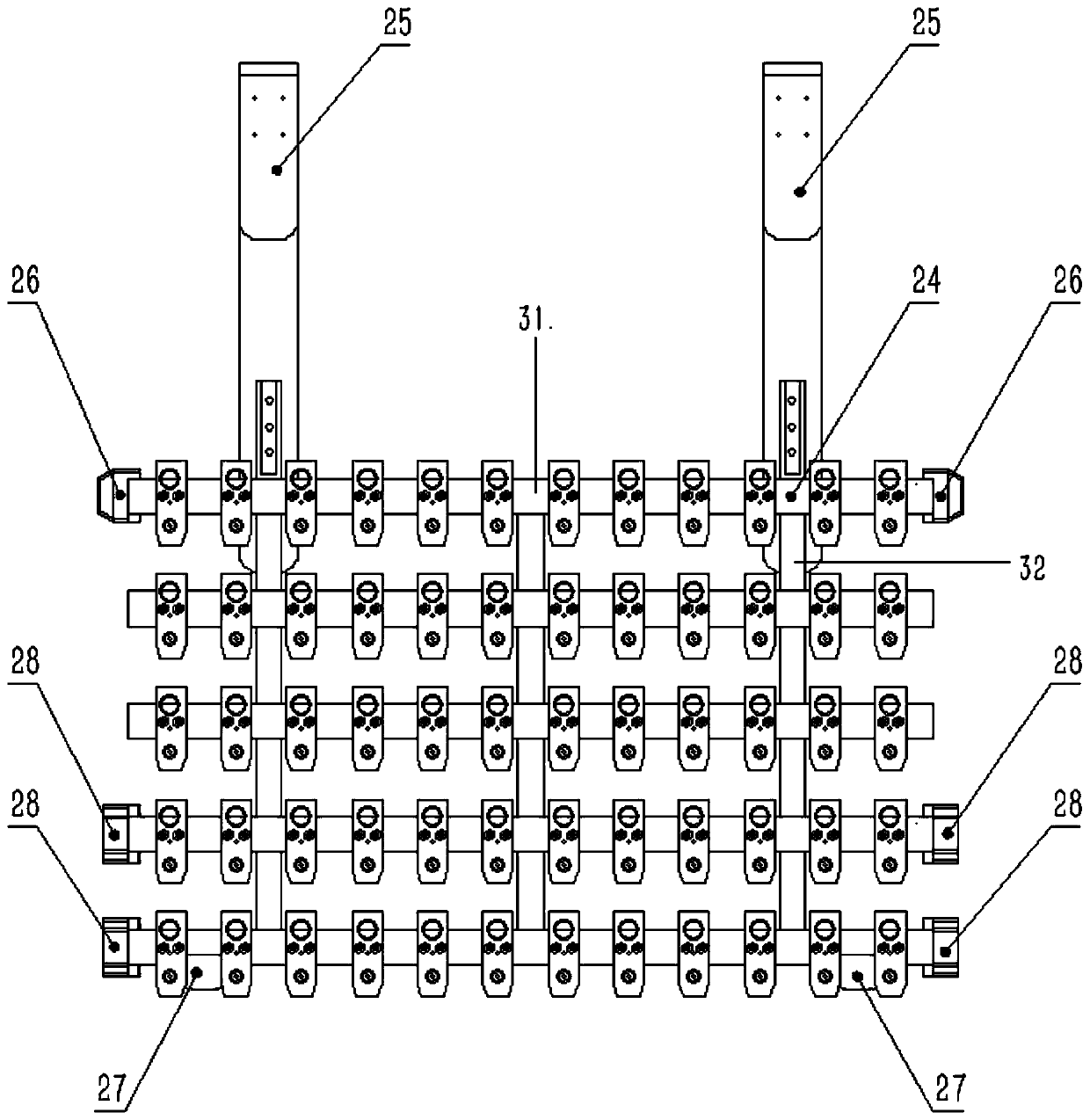

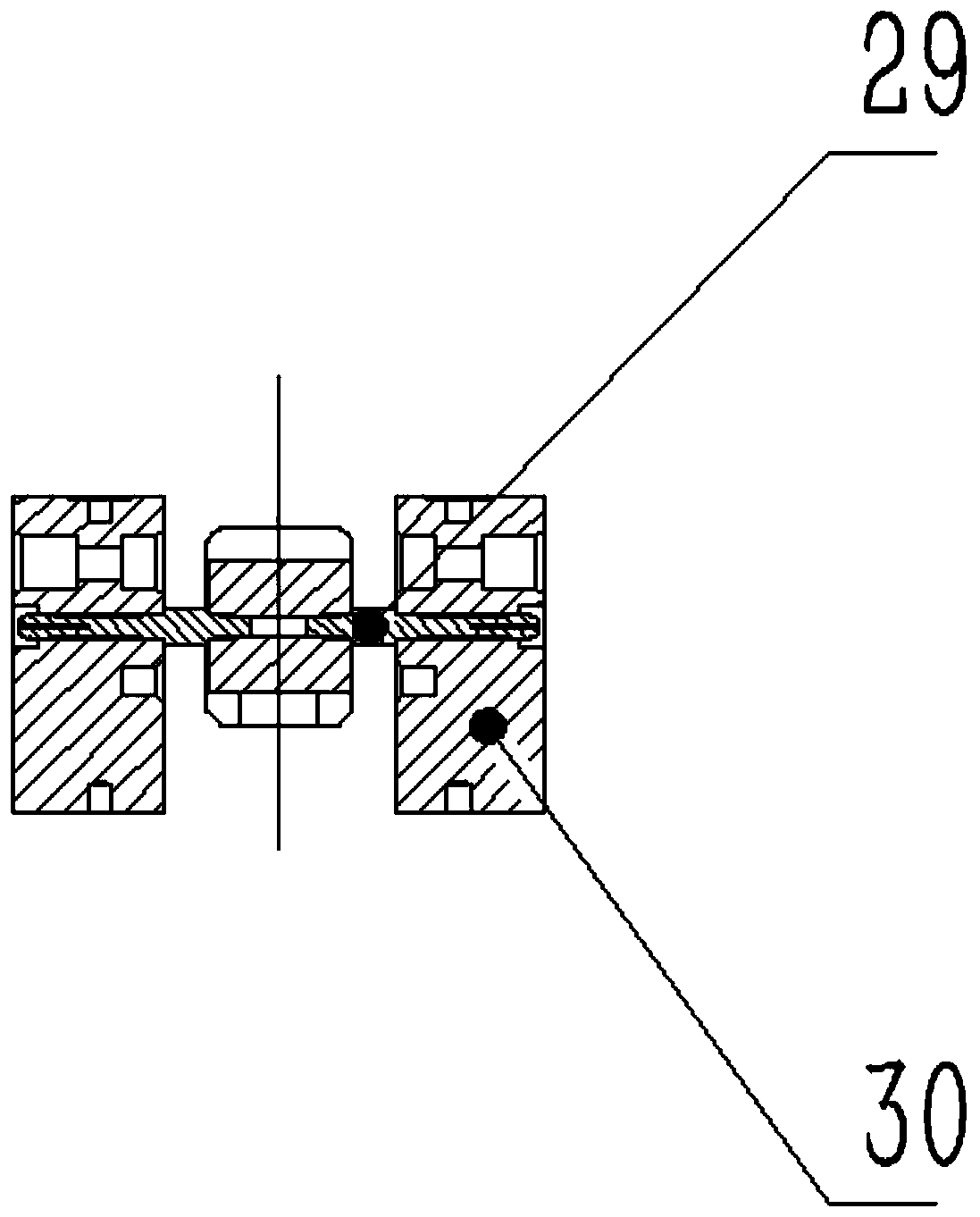

[0032] see Figure 1-3 , this embodiment provides a high-precision hanger for expansion valve oxidation line, including hanger base 24, and the hanger base 24 is an integrally formed structure composed of a plurality of transverse supports 31 and longitudinal supports 32. The front and back sides of the transverse support 31 are fixedly provided with a number of elastic positioning pins 29 for fixing the expansion valve 30, and the two sides of the transverse support 31 on the top are provided with top V-shaped blocks 26 for side positioning, The two sides of the lateral support 31 are provided with guide sliders 28 that are conducive to sliding, the bottom surface of the lateral support 31 at the bottom is provided with a bottom V-shaped block 27 for lower positioning and limiting, and the top of the longitudinal support 32 is provided with a bottom V-shaped block 27 . Hook 25. The high-precision hanger of the present invention is mainly composed of an elastic positioning pi...

Embodiment 2

[0037] see Figure 4-6, this embodiment provides a positioning mechanism for the high-precision hanger for the oxidation line of the expansion valve described in the first embodiment, including a base 1, a V-shaped block 2, a guide clamping mechanism 3, a buffer device 4, and a gantry flying handle. 5. Support seat 6, high-precision hanger 7 and V-shaped support seat 8. A support seat 6 is installed on both sides of the base 1, and the support seat 6 is provided with a V-shaped support seat 8 that is positioned in coordination with the gantry flying handle 5. The high-precision hanger 7 is driven by the gantry to move and can be moved. Detach from the gantry flying handle 5; the position of the bottom V-shaped block 27 corresponding to the high-precision hanger 7 on the base 1 is fixed with a V-shaped block 2 cooperating with the bottom V-shaped block 27; The two sides of the precision hanger 7 are fixed with a guide clamping mechanism 3 for pressing and positioning the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com