Process method for optimizing uniformity on pyramid suede

A process method and pyramid technology, applied in the direction of metal material coating process, gaseous chemical plating, climate sustainability, etc., can solve the problems of poor uniformity of aluminum oxide film, uneven aluminum oxide film, EL black spots, etc. Improved uniformity, improved passivation effect, enhanced chemical passivation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

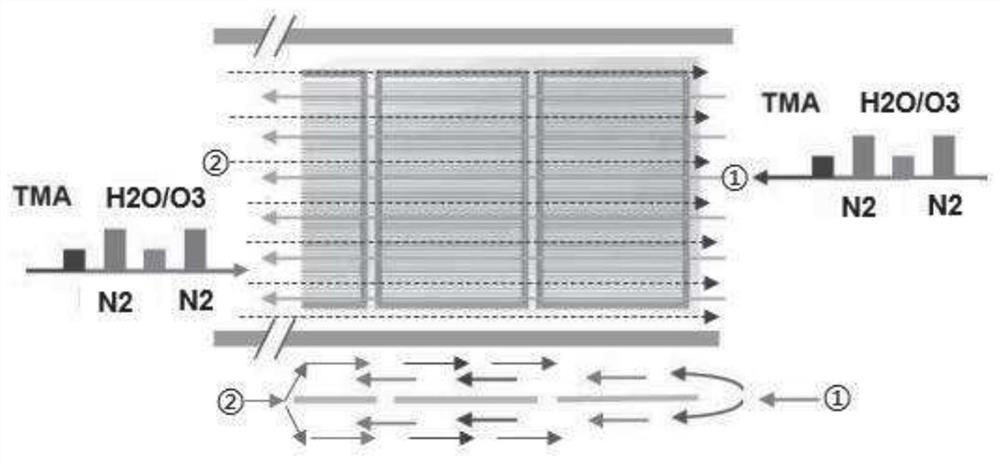

[0031] refer to image 3 and Figure 4 , the process method of optimizing the uniformity on the pyramid suede surface of the present invention, comprises the following steps S1~S4:

[0032] Step S1: Provide raw silicon wafers for solar cells, perform texturing and growth of pyramid texture on the raw silicon wafers, and then perform cleaning and pretreatment of the texture; further include the following steps 1a-1b:

[0033] Step 1a: Provide raw silicon wafers for solar cells. The silicon wafer described in this embodiment is a polycrystalline silicon wafer with a resistivity of 0-6 ohm·m (Ω·m) and a thickness of 120um-230um. The present invention is also applicable to monocrystalline silicon wafers of various sizes and types.

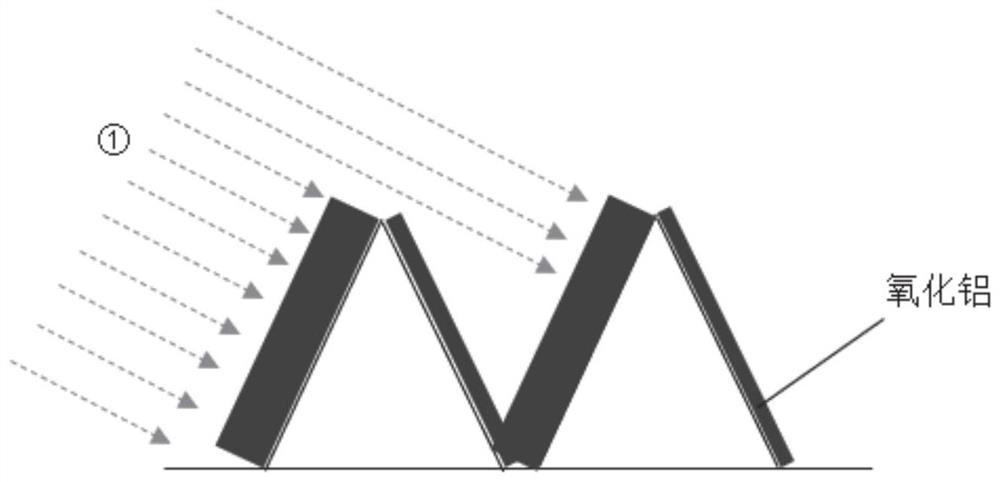

[0034] Step 1b: Texturing and cleaning the original silicon wafer. Utilizing the characteristics of alkali anisotropic corrosion, adding appropriate additives such as alkali texturizing solution, etch a pyramid-structured texture on the silicon wafe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com