Reinforced constraint type rectangular concrete-filled steel tube column and construction method

A rectangular steel tube and concrete column technology, applied in the directions of columns, piers, pillars, etc., can solve the problems of weak internal concrete restraint and small bearing capacity, and achieve the effects of convenient construction, high bearing capacity and improved compressive strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

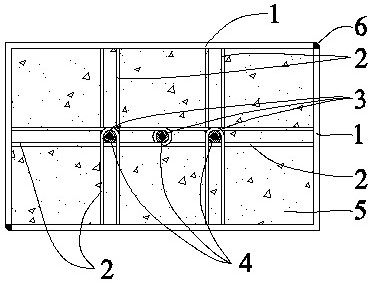

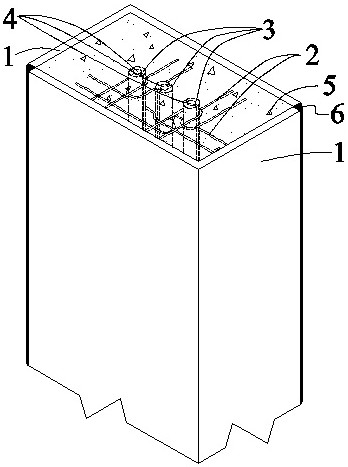

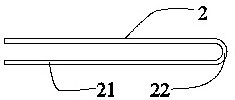

[0022] Such as figure 1 , figure 2 As shown, a reinforced and restrained rectangular concrete-filled steel tube column is composed of L-shaped steel plates (1), restraint rods (2), locking rods (3), inner struts (4) and concrete (5); the restraint rods (2 ), the locking rod (3) and the inner support rod (4) are all steel components; two L-shaped steel plates (1) are spliced to form a rectangular steel pipe, and the splicing position is connected by a fillet weld (6); the restraint rod (2) is welded on On the two inner sides of the L-shaped steel plate (1), the restraining rods (2) are evenly arranged along the height direction of the L-shaped steel plate (1), and the heights of the restraining rods (2) on the two inner sides of the L-shaped steel plate (1) are different , the number of restraint rods (2) at the same height is determined according to the limb length and design requirements of the L-shaped steel plate (1), at least one, and there are two restraint rods (2) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com