A kind of homogeneous high-strength cocrni-b medium entropy alloy and preparation method thereof

An entropy alloy and high-strength technology, applied in the field of homogeneous high-strength CoCrNi-B medium-entropy alloy and its preparation, can solve the problems of low mechanical performance index, high cost, and affecting safe service, etc., achieve good strength and toughness index, and reduce melting consumption Energy, the effect of reducing the melting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

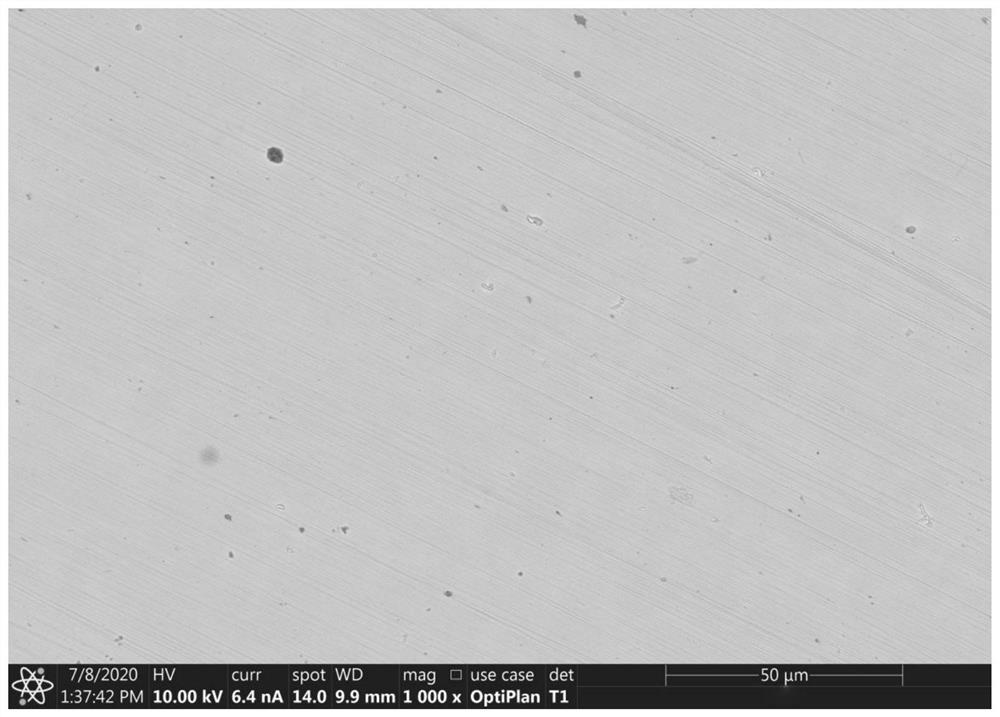

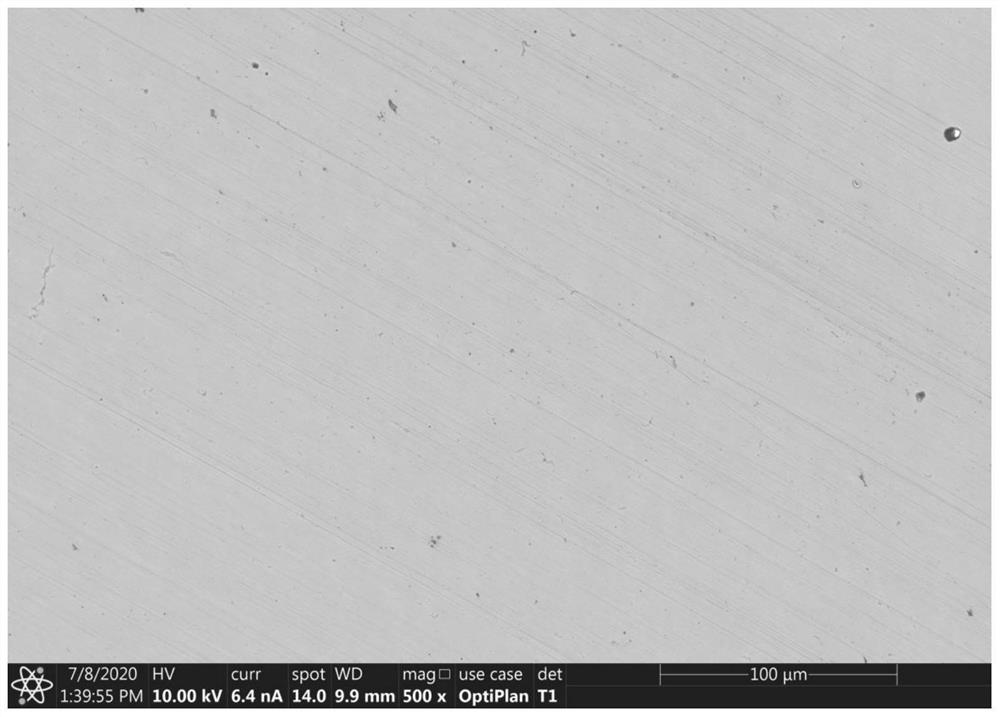

Image

Examples

preparation example Construction

[0041] The preparation method of homogeneous high-strength CoCrNi-B medium entropy alloy of the present invention comprises the steps:

[0042] (1) Ingredients: Take raw materials Co, Ni, Cr and B according to the specified ratio.

[0043] (2) High-energy ball milling: Add raw materials Cr and B into a vacuum ball milling tank for ball milling, the ball milling medium is absolute ethanol, the ball-to-material ratio is 10-80:1, the rotating speed is 350-550rpm, and the ball milling time is 1-24h; ball milling After the completion, the ball mill slurry was left to stand in a vacuum environment for 2-10 hours, then the upper clear liquid was removed, and the bottom sediment was dried in a vacuum drying oven at a drying temperature of 55-80°C to obtain Cr-B composite powder.

[0044] (3) Low-temperature curing pre-sintering: the Cr-B composite powder compact prepared in step (2) is subjected to low-temperature curing pre-sintering treatment in a vacuum tube furnace to obtain a Cr-...

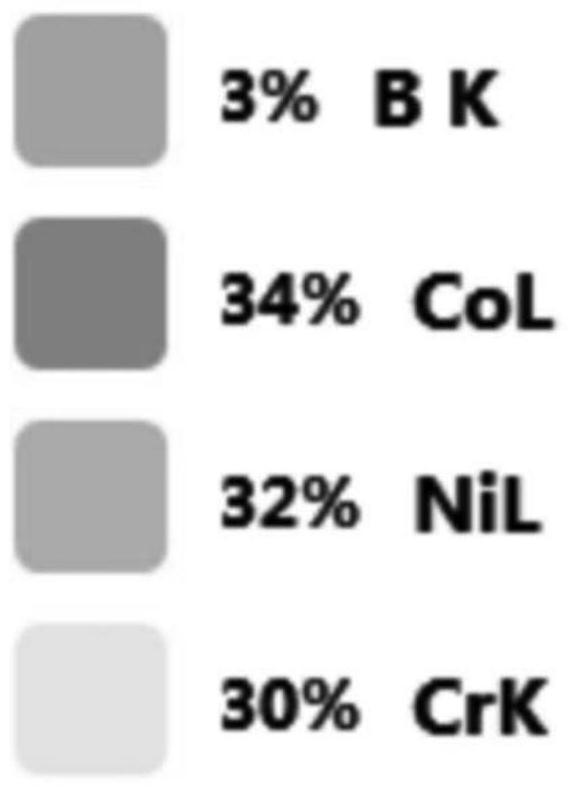

Embodiment 1

[0055] A homogeneous high-strength (CoCrNi) 99.92 B 0.08 The preparation method of medium entropy alloy, the preparation method is as follows:

[0056] (1) Ingredients

[0057] Cr: 30.7g, superfine chromium powder;

[0058] Co: 34.7g, block, particle size about 1cm;

[0059] Ni: 34.6g, granular, particle size 1-5mm;

[0060] B: 0.08g, high-purity powder, 400 mesh.

[0061] (2) High energy ball mill

[0062] Add high-purity Cr powder and B powder into a vacuum ball mill tank, use absolute ethanol as the ball mill medium; the ball-to-material ratio is 60:1, the rotation speed is 450 rpm, the ball milling time is 6 hours, and the ball milling aid is stearic acid.

[0063] After ball milling, transfer the ball mill slurry to a beaker, and let it stand in a vacuum environment for 2 hours until the upper layer of the beaker is obviously clear, and the Cr-B composite powder settles at the bottom. In the vacuum glove box, use a pipette to remove the upper clear liquid, transfer...

Embodiment 2

[0072] A homogeneous high-strength (CoCrNi) 99.95 B 0.05 Medium entropy alloy, the preparation method is as follows:

[0073] (1) Ingredients

[0074] Cr: 30.7g, superfine chromium powder;

[0075] Co: 34.7g, block, particle size about 1cm;

[0076] Ni: 34.6g, granular, particle size 1-5mm;

[0077] B: 0.05g, high-purity powder, 400 mesh.

[0078] (2) High energy ball mill

[0079] Add the high-purity Cr powder and B powder into the vacuum ball mill tank, and use absolute ethanol as the ball mill medium;

[0080] The ball-to-material ratio is 40:1, the rotation speed is 350rpm, the ball milling time is 12h, and the ball milling aid is stearic acid;

[0081] After ball milling, transfer the ball mill slurry to a beaker, and let it stand in a vacuum environment for 2 hours until the upper layer of the beaker is obviously clear, and the Cr-B composite powder settles at the bottom. In a vacuum glove box, using a pipette, remove the supernatant liquid. Transfer the Cr-B co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com