Super-tough dry-mixed mortar and preparation method thereof

A dry powder mortar and toughness technology, applied in the field of dry powder mortar and its preparation, can solve the problems of uneven mixing, low mortar measurement accuracy, poor mortar stability, etc., and achieves low price, mature extraction method, and improved toughness and anti-cracking performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of super-toughness dry powder mortar comprises the following steps:

[0025] (1) Iron tailings are selected as tailings, crushed, and fine aggregates of 50-100 mesh, 100-150 mesh, and 50 mesh or less are screened out, blended according to 1:1.5:0.1, and mixed evenly for later use;

[0026] (2) Weigh 150 parts of Portland cement, 2 parts of admixture, and 1.5 parts of anthocyanin powder. The admixture includes redispersible latex powder, cellulose ether, air-entraining agent and polypropylene fiber, according to available The weight ratio of redispersing latex powder, cellulose ether, air-entraining agent and polypropylene fiber is 1:0.25:0.05:0.125 to obtain A component, measure and pack it, and record it as A bag;

[0027] (3) According to the mass ratio of construction sand and tailings of 1:0.2, weigh 300 parts of construction sand and 60 parts of iron tailings and mix them evenly to obtain component B, measure and pack them into bags, and reco...

Embodiment 2

[0031] The preparation method of super-toughness dry powder mortar comprises the following steps:

[0032] (1) Iron tailings are selected as tailings, crushed, and fine aggregates of 50-100 mesh, 100-150 mesh, and 50 mesh or less are screened out, blended according to 1:1.2:0.05, and mixed evenly for later use;

[0033] (2) Weigh 150 parts of ordinary Portland cement, 5 parts of admixture, and 4 parts of glucose powder. The admixture includes redispersible latex powder, cellulose ether, air-entraining agent and polypropylene fiber. The weight ratio of dispersed latex powder, cellulose ether, air-entraining agent and polypropylene fiber is 1:0.25:0.05:0.125 to obtain A component, which is measured and packed into bags, which is recorded as A bag;

[0034] (3) According to the mass ratio of construction sand and tailings of 1:0.3, weigh 300 parts of construction sand and 90 parts of iron tailings and mix them uniformly to obtain component B, measure and pack them into bags, and ...

Embodiment 3~6

[0037] It is basically the same as Example 2, except that the dosage of glucose in Examples 3 to 6 is 0 parts, 2 parts, 6 parts, and 8 parts respectively.

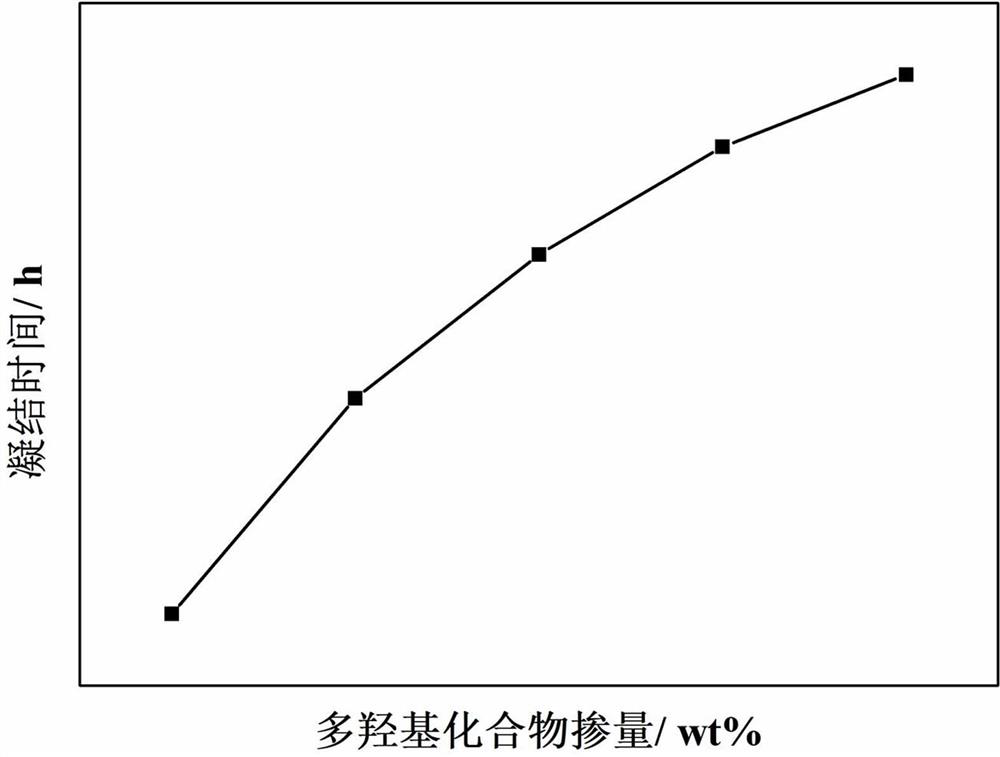

[0038] Embodiment 2~6 all mixes with 45 parts of waters and obtains the mortar of mixing thoroughly, measures the coagulation time of the prepared mortar of embodiment 2~6, and result schematic diagram is as follows figure 1 shown. Depend on figure 1 It can be seen that with the increase of glucose content, the setting time of mortar increases, and the setting time can be adjusted according to the content of glucose in application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com