Household equipment for rapidly making cakes

A fast, cake-like technology, applied in home utensils, applications, kitchen utensils, etc., can solve the problems of inconsistent shape and weight, low cake work efficiency, etc., to achieve a high degree of automation and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

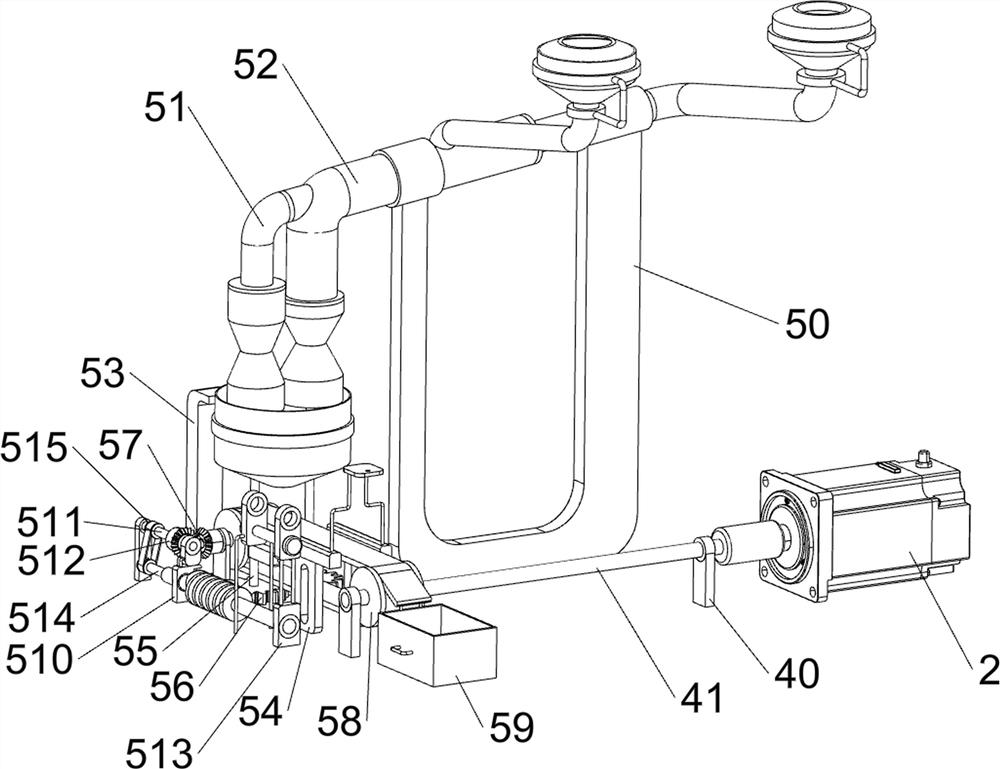

[0091] A kind of equipment for home quick cake making, such as figure 1 As shown, it includes a bottom plate 1, a servo motor 2, a transmission mechanism 3, an eggshell collecting mechanism 4, a mixing and transporting mechanism 5 and a baking mechanism 6. The servo motor 2 is arranged in the middle right side of the top of the bottom plate 1, and the front side of the top of the bottom plate 1 is provided with a There is a transmission mechanism 3, an eggshell collection mechanism 4 is arranged between the transmission mechanism 3 and the output shaft of the servo motor 2, a stirring transport mechanism 5 is provided on the rear left side of the bottom plate 1 top, and a baking mechanism 6 is arranged on the stirring transport mechanism 5.

[0092] When people need to make cakes, first put the eggs on the transmission mechanism 3, then put other raw materials into the stirring and transporting mechanism 5, then start the servo motor 2 and the baking mechanism 6, and the output...

Embodiment 2

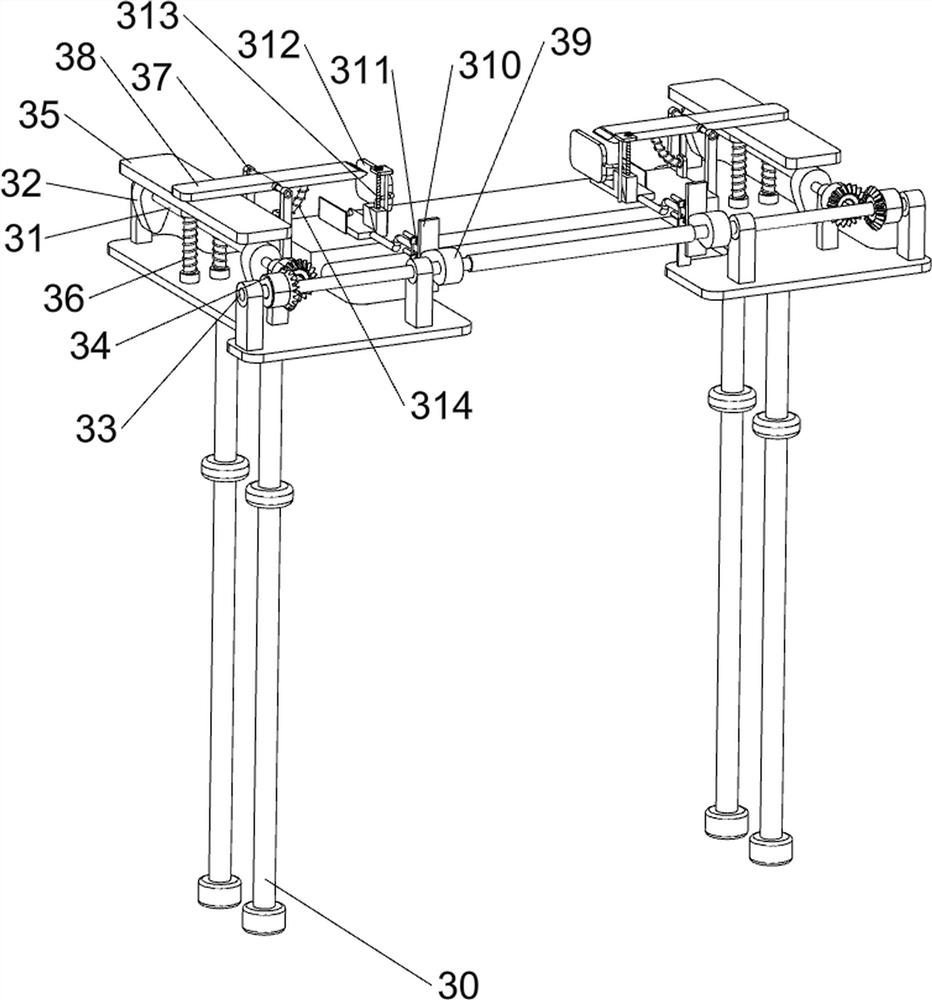

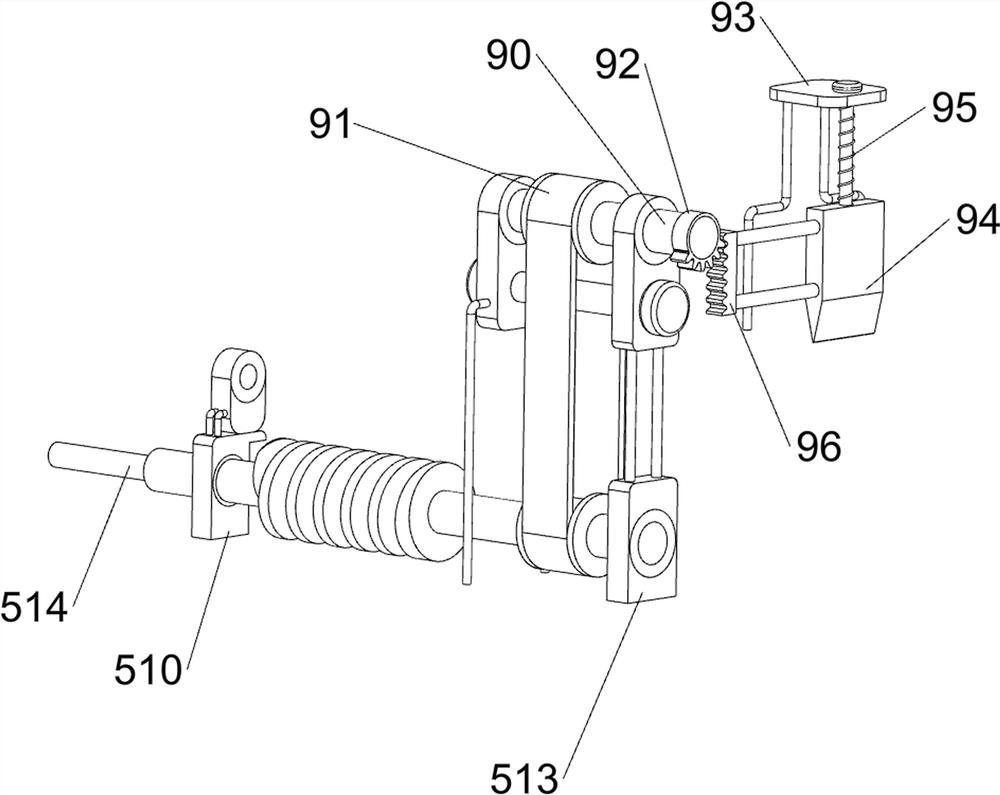

[0094] On the basis of Example 1, such as figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the transmission mechanism 3 includes an underframe 30, a first rotating shaft 31, a first cam 32, a second rotating shaft 33, a first bevel gear assembly 34, a lifting block 35, a first spring 36, a rotating rod 37, a rotating Block 38, second cam 39, push block 310, second spring 311, inclined block baffle plate 312, third spring 313 and fourth spring 314, base plate 1 top front side is provided with underframe 30, and underframe 30 top left and right symmetrical The rotary type is provided with a first rotating shaft 31, and the front and rear sides of the first rotating shaft 31 are provided with first cams 32. The rotating type on the front side of the bottom frame 30 is provided with a second rotating shaft 33. The first bevel gear assembly 34 is arranged between the second rotation shaft 33, and the bottom frame 30 is symmetrically slidable with a lifting b...

Embodiment 3

[0102] On the basis of Example 2, such as Figure 7 , Figure 8 and Figure 9 As shown, it also includes a blanking mechanism 7. The blanking mechanism 7 includes a ferrule 70, a feed pipe 71 and a buffer assembly 72. The top of the bottom frame 30 is symmetrically provided with a ferrule 70. Both the feeding pipe 71 and the feeding pipe 71 are slidably connected to the same side inclined block baffle 312 , and the inside of the feeding pipe 71 is uniformly provided with a buffer assembly 72 .

[0103] When people need to make cakes, all the eggs are put into the feed pipe 71 first, and under the effect of the buffer assembly 72, the eggs will not break in the feed pipe 71. When the eggs contact the inclined block baffle plate 312 , the egg stops moving, when the inclined block baffle plate 312 moves upwards, under the action of gravity, the egg rolls down to the bottom frame 30, and the pushing block 310 plays a positioning role, so that the rotating block 38 breaks the egg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com