Phosphorus-doped heterogeneous nickel-cobalt sulfide composite material and preparation method and application thereof

A nickel-cobalt sulfide and composite material technology, applied in the field of materials, can solve the volume expansion of transition metal sulfide electrode materials, limit the wide application of supercapacitors, and capacity fading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

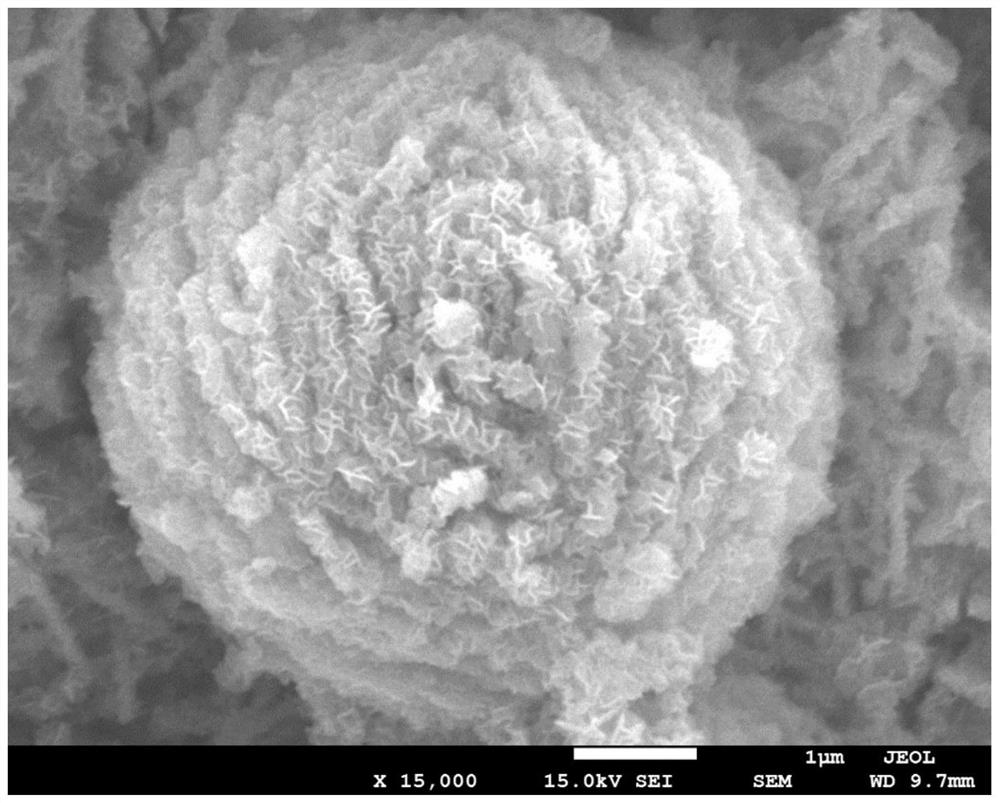

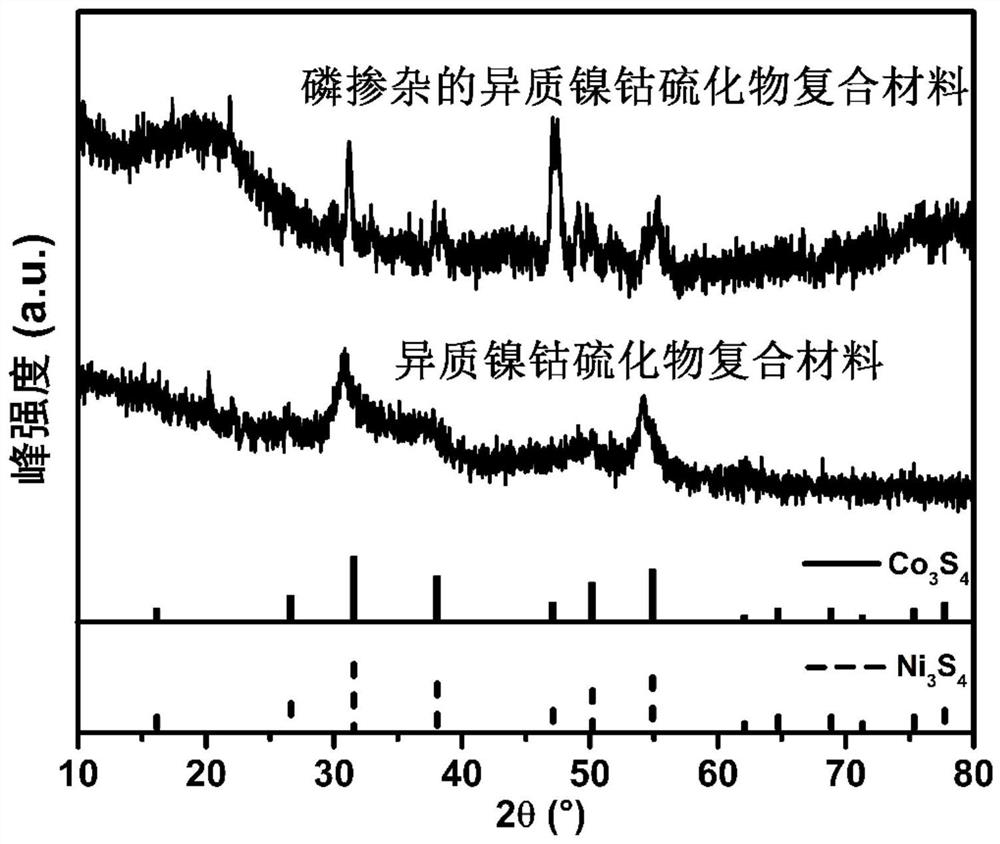

[0057] (1) A preparation method of a phosphorus-doped heterogeneous nickel-cobalt sulfide composite material, comprising the following steps:

[0058] 1) Dissolve 1.45g of cobalt nitrate and 1g of sodium lauryl sulfate in a mixed solution of 35mL of methanol and 5mL of water. After stirring into a pink homogeneous solution, soak a piece of nickel foam (3cm×5cm) that has been washed several times with acetone, hydrochloric acid, and ultrapure water into the above solution, and then transfer the mixed solution into 50mL polytetrafluoroethylene In the lining, heat to 180°C for 10 hours. After the reactor was naturally cooled to room temperature, the nickel foam was taken out, washed several times with absolute ethanol and ultrapure water, and then vacuum-dried at 80°C for 12 hours to obtain the nickel foam loaded with Co precursor;

[0059] 2) Transfer the nickel foam loaded with Co precursor obtained in step 1) to a muffle furnace, place it in an air atmosphere, raise the tempe...

Embodiment 2

[0073] (1) A preparation method of a phosphorus-doped heterogeneous nickel-cobalt sulfide composite material, comprising the following steps:

[0074] 1) operation is with the step 1) of embodiment 1;

[0075] 2) Transfer the nickel foam loaded with Co precursor obtained in step 1) to a muffle furnace, place it in an air atmosphere, raise the temperature to 400°C at a heating rate of 2°C / min, and keep it warm for 2h to obtain nano flower nickel foam;

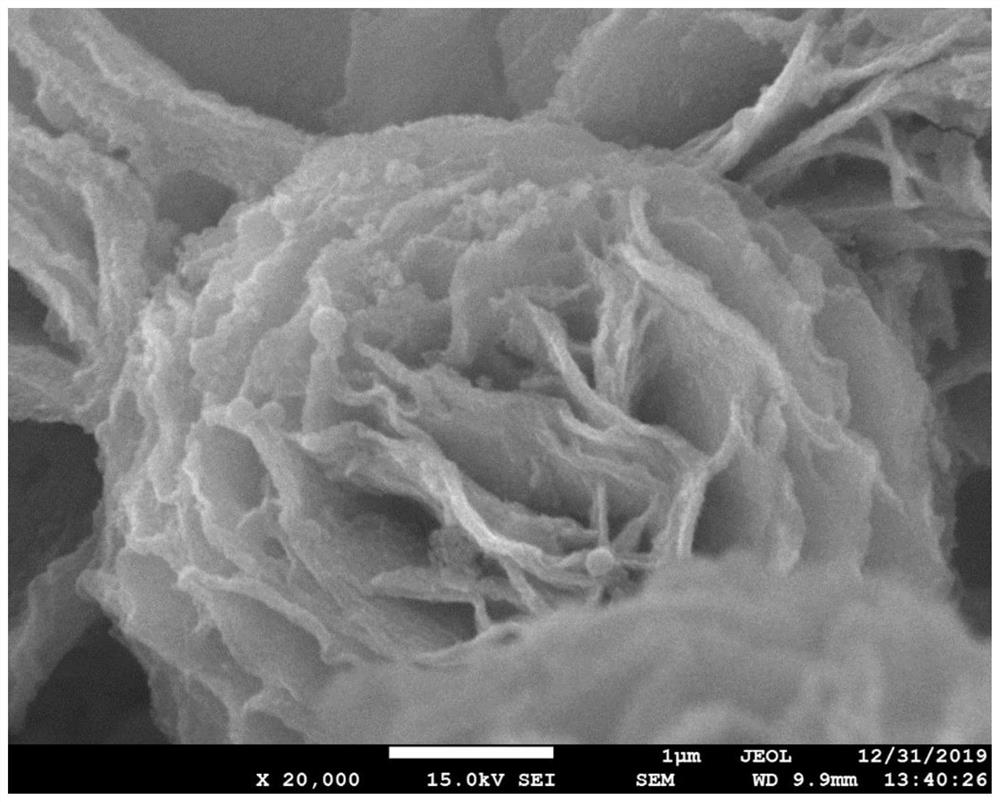

[0076] 3) Immerse the nickel foam loaded with tricobalt tetroxide obtained in step 2) into 40 mL of absolute ethanol solution containing 0.63 g of nickel acetate tetrahydrate and 0.56 g of thioacetamide, and then transfer the material to a 50 mL autoclave at a constant temperature of 120 ° C. Reaction 2h. After cooling, wash the nickel foam several times with ultrapure water and ethanol, and finally dry it at 80°C for 12 hours to obtain heterogeneous nickel-cobalt sulfide nanocomposites;

[0077] 4) Place the product of step ...

Embodiment 3

[0085] (1) A preparation method of a phosphorus-doped heterogeneous nickel-cobalt sulfide composite material, comprising the following steps:

[0086] 1) operation is with the step 1) of embodiment 1;

[0087] 2) Transfer the nickel foam loaded with Co precursor obtained in step 1) to a muffle furnace, place it in an air atmosphere, raise the temperature to 400°C at a heating rate of 2°C / min, and keep it warm for 2h to obtain nano flower nickel foam;

[0088] 3) Immerse the nickel foam loaded with tricobalt tetroxide obtained in step 2) into 40 mL of absolute ethanol solution containing 0.63 g of nickel acetate tetrahydrate and 0.56 g of thioacetamide, and then transfer the material to a 50 mL autoclave at a constant temperature of 120 ° C. Reaction 2h. After cooling, wash the nickel foam several times with ultrapure water and ethanol, and finally dry it at 80°C for 12 hours to obtain heterogeneous nickel-cobalt sulfide nanocomposites;

[0089] 4) Put the product obtained i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com