Path planning and shimmy damping control method of four-rotor variable-rope-length hanging system

A path planning and control method technology, applied in the field of quadrotor control, can solve the problems of model establishment, such as accuracy dependence, long time, and low robustness to interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

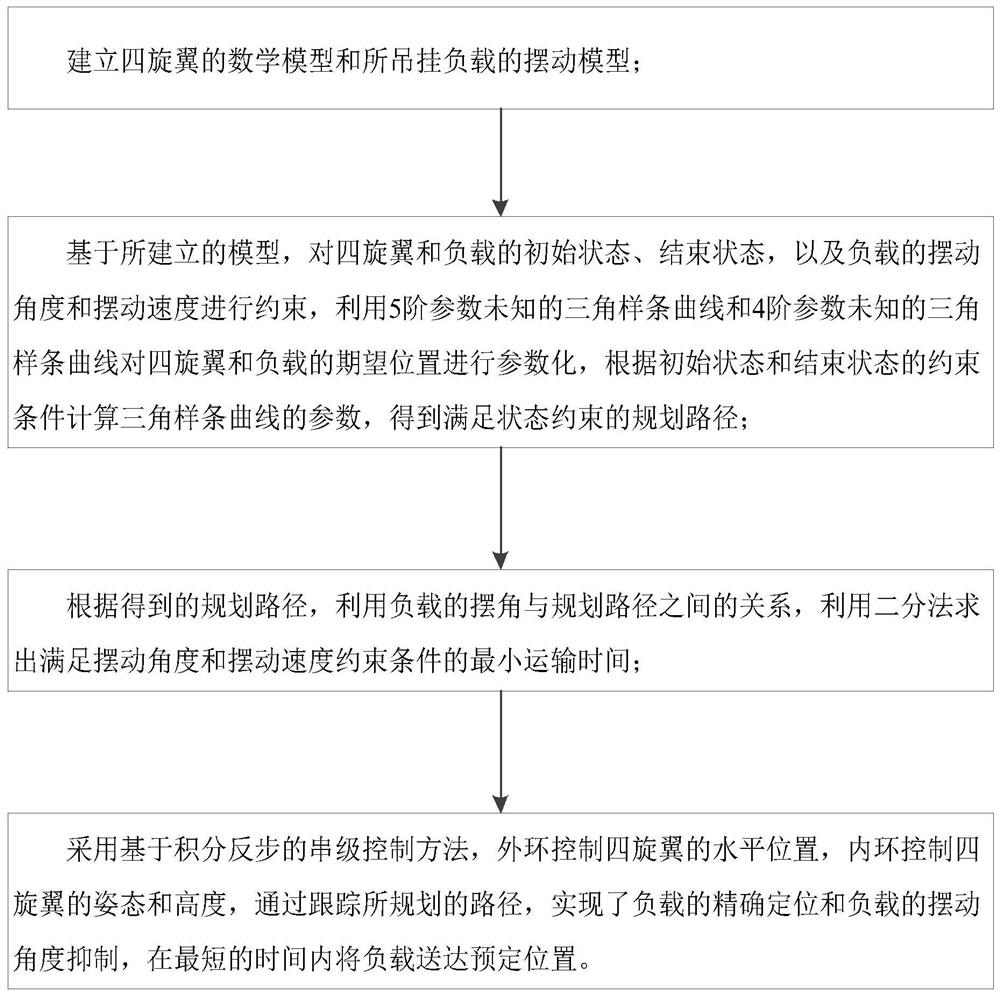

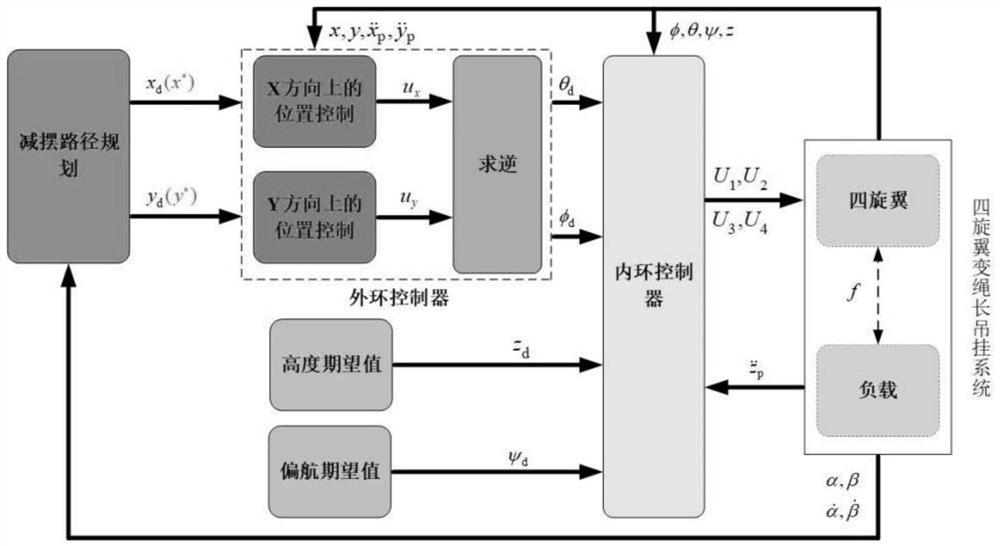

Method used

Image

Examples

Embodiment 1

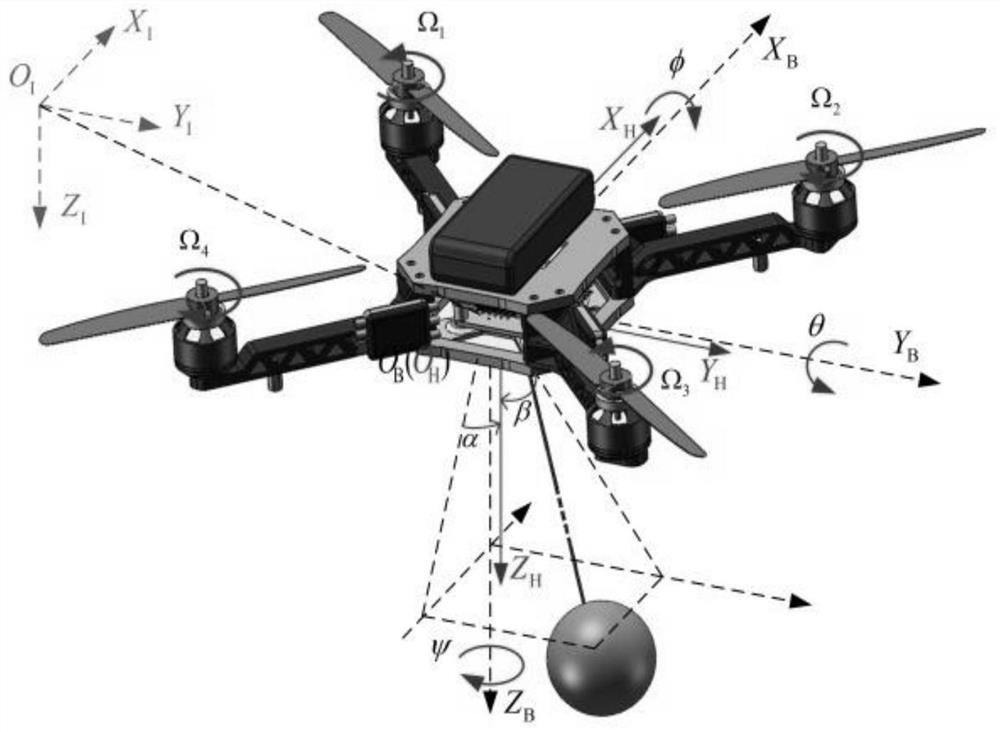

[0208] Setting parameters: quadrotor mass M = 1.4kg, load mass m = 0.25kg, gravity acceleration g = 9.81m / s 2 , moment of inertia J x =0.0087kg·m 2 ,J y =0.0087kg·m 2 ,J z =0.016kg·m 2 ,J r =9.89e-5kg·m 2, the length of the sling changes with time as L=1+0.1t m, the distance between the motor and the center of the quadrotor is d=0.18m, and the initial position of the quadrotor is [x r0 ,y r0 ,z r0 ]=[0,0,0], the expected position is [x r ,y r ,z r ]=[3,4,5], the upper and lower limits of the transportation time T are T l =4s,T u =7s, limit the maximum swing angle to α max = β max =0.3rad, the maximum swing rate is The T value calculated by dichotomy is 5.0313.

[0209] The quadrotor reference trajectory calculated according to the above method is:

[0210]

[0211]

[0212] Simulation experiment: use matlab for simulation analysis, see the simulation results Figure 5-Figure 12 . The results show that the quadrotor can carry the load and move to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com