Double-cathode intermittent copper polishing method

A dual-cathode, polishing solution technology, applied in the field of electrochemistry, can solve the problems of high copper surface roughness, increased polishing current, and different material removal rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

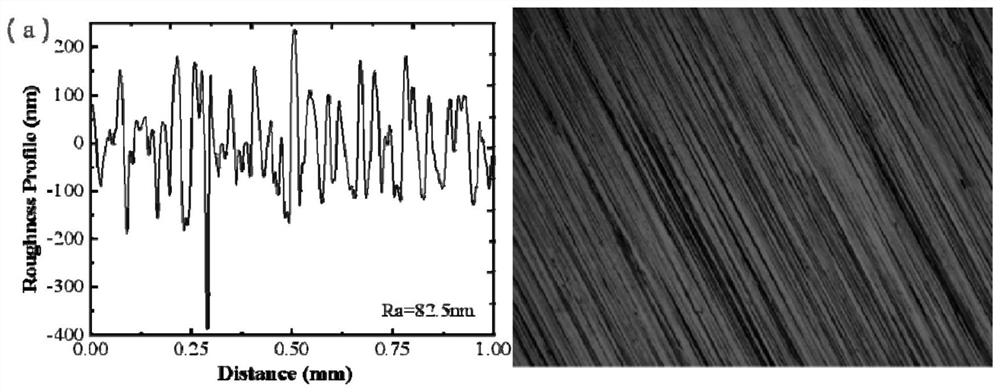

example 1

[0023] (1) Prepare a polishing solution, which contains phosphoric acid at a concentration of 55wt%, ascorbic acid at a concentration of 0.3wt%, and ethylene thiourea at a concentration of 0.2wt%. What this example adopts is the phosphoric acid solution that purity is 85%, the ascorbic acid that purity is 99% and the ethylene thiourea that purity is 97%. Weigh 129.4g of phosphoric acid, 0.6g of ascorbic acid, and 0.4g of ethylene thiourea into a reaction dish, add 69.4g of water, stir well and cool to room temperature.

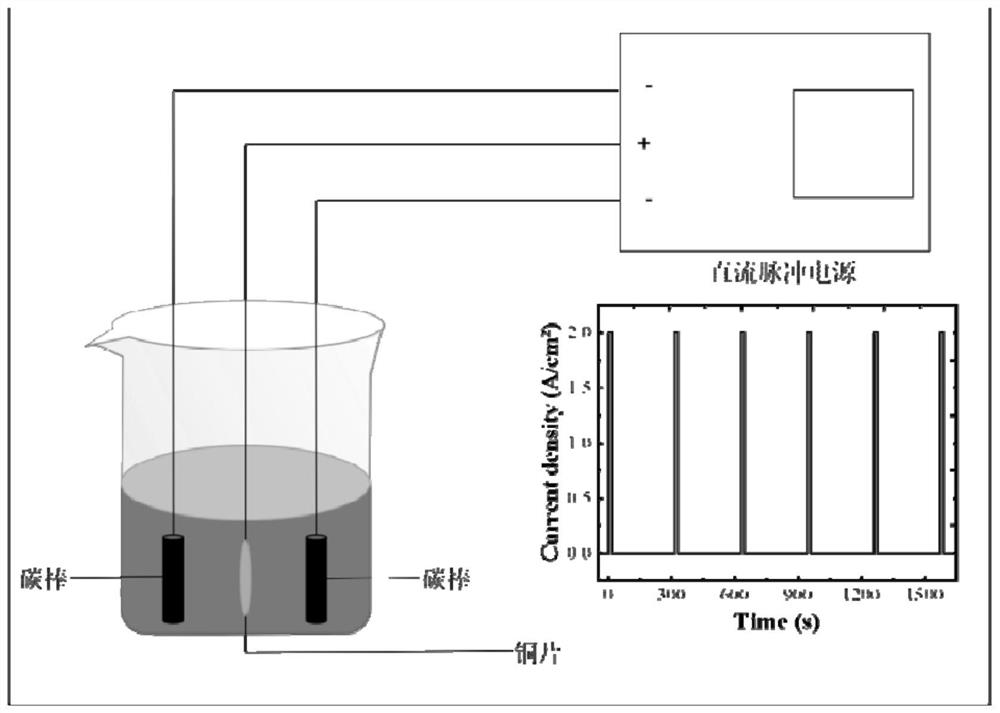

[0024] (2) Immerse two carbon rods in the reaction vessel as the cathode, place the copper sheet to be polished between the two carbon rods as the anode, and turn on the power to polish both sides of the copper sheet at the same time. Among them, the current density during the polishing process is 2A / cm 2 , The polishing time is 90s.

[0025] (3) After the polishing is completed, take out the copper sheet, wash off the residual phosphoric acid on the surface...

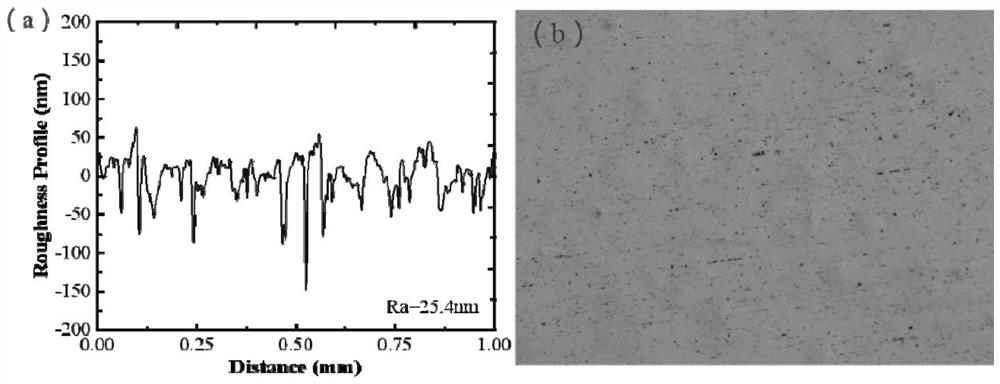

example 2

[0027] (1) Prepare a polishing solution, which contains phosphoric acid at a concentration of 55wt%, ascorbic acid at a concentration of 0.3wt%, and ethylene thiourea at a concentration of 0.2wt%. What this example adopts is the phosphoric acid solution that purity is 85%, the ascorbic acid that purity is 99% and the ethylene thiourea that purity is 97%. Weigh 129.4g of phosphoric acid, 0.6g of ascorbic acid, and 0.4g of ethylene thiourea into a reaction dish, add 69.4g of water, stir well and cool to room temperature.

[0028] (2) Immerse two carbon rods in the reaction vessel as the cathode, place the copper sheet to be polished between the two carbon rods as the anode, and turn on the power to perform intermittent polishing on both sides of the copper sheet at the same time. Among them, the current density during the polishing process is 2A / cm 2 , each polishing time is 15s, the intermittent time is 5min, and the number of polishing times is 6 times.

[0029] (3) After th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com