Batch sintering method of high-performance silicon nitride ceramic substrate

A technology of silicon nitride ceramics and sintering method, which is applied in the field of batch sintering of high-performance silicon nitride ceramic substrates, and can solve the problems of affecting the consistency of material properties, polluting substrate materials, and exacerbating the uneven temperature inside the furnace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

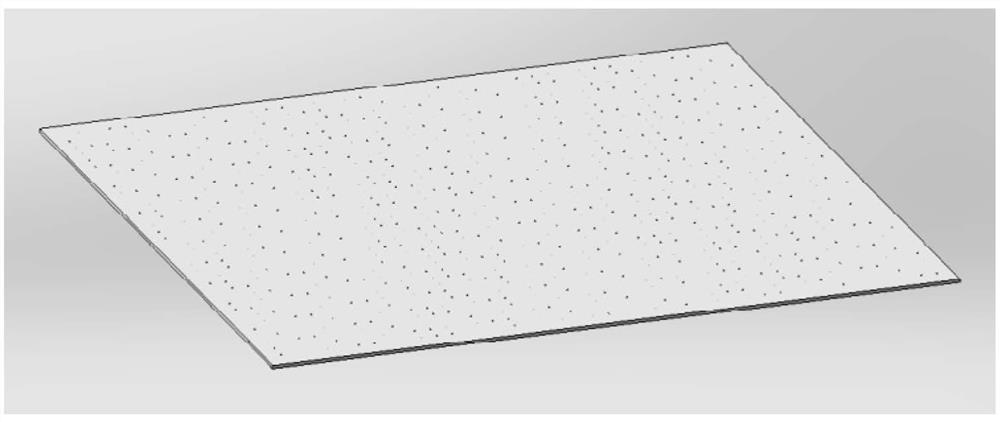

Image

Examples

preparation example Construction

[0039] Preparation of silicon nitride ceramic substrate green body. Specifically, the silicon nitride ceramic substrate green body is prepared through processes such as slurry preparation, vacuum degassing, tape casting, green body drying, and green body shaping in the tape casting preparation process.

[0040] In the present invention, the purpose of reducing or eliminating air bubbles in the slurry and reducing agglomeration in the slurry is achieved through sufficient ball milling and mixing under a protective atmosphere during the preparation of the casting slurry, combined with low vacuum and long-term degassing treatment. Through the precise control of the cylindrical scraper and its height during the tape casting process, and the continuous thermal N with increasing temperature 2 Atmospheric drying treatment measures for cast film blanks to achieve high-quality, defect-free cast film preparation and precise control of thickness uniformity. N during compounding and tape...

Embodiment 1

[0053] Firstly, a silicon nitride ceramic substrate blank with a thickness of 0.4mm was prepared by wet mixing, vacuum degassing, tape casting and other processes; Boron slurry, after the slurry is dried, cut it into 88mm×73mm samples, stack 20 samples of the same specification above and place them in a high-purity boron nitride crucible with an internal space of 100mm×100mm×30mm;

[0054] Secondly, the boron nitride crucible containing the silicon nitride ceramic substrate blank is evenly and regularly placed on the sintering tooling (or graphite kiln furniture) composed of a high-purity graphite multi-layer shed structure, and it is loaded into the air pressure in the sintering furnace;

[0055] Third, perform heat treatment according to the following process sequence: (1) Vacuumize for 15 minutes to make the vacuum degree reach 65-75kPa, continue to vacuumize for 15 minutes to make the vacuum degree reach 15-25kPa, then evacuate for 15 minutes to make the vacuum degree reac...

Embodiment 2-5

[0058] Green body size, characteristics of boron nitride powder for substrate green isolation (impurity content, average particle size, coating amount), substrate green stacking quantity, vacuuming process, graphite grid structure, debonding process, The specific parameters such as the sintering process are shown in Table 1 and Table 2, the process is referred to in Example 1, and the characteristics of the prepared substrate material are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Breakdown field strength | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com