Method for preparing high-strength and high-thermal-conductivity aluminum nitride through hot pressed sintering

A hot-pressing sintering, high thermal conductivity technology, applied in the field of high-strength and high-strength hot-pressing sintering, can solve the problems of reducing liquid phase, unfavorable densification, reduction and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

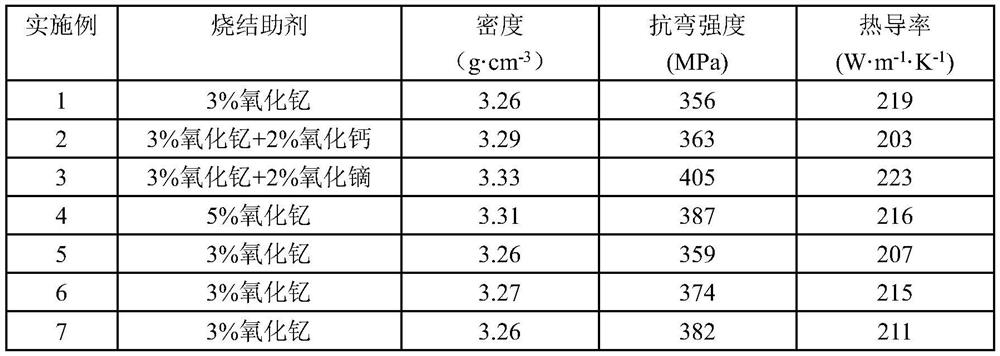

Examples

Embodiment 1

[0024] Weigh 50.00g of aluminum nitride, 1.54g of yttrium oxide, 2.79g of PVB and 200ml of alcohol into a ball mill jar, mix evenly at a speed of 70 rpm, put the suspension into a drying oven for drying, grind and sieve each Take 1.5g of the mixture and mold it into a φ15 disc. Put the pattern into a tube furnace for degreasing under nitrogen atmosphere, raise the temperature to 450°C at a rate of 5°C / min, keep it warm for 3 hours and then cool down with the furnace to obtain an aluminum nitride green body. Put the green body into a graphite crucible and raise the temperature up to 1500°C at a rate of 10°C / min, then keep it warm in flowing nitrogen for 4h for pre-sintering. Then put the pre-sintered sample into a hot-pressed graphite mold, raise the temperature to 1750 °C at a rate of 10 °C / min, and then apply a pressure of 30 MPa and keep it for 2 h. Then put it into a graphite furnace and raise it to 1800°C at 10°C / min for 5 hours, then cool it down to 1000°C at 10°C / min an...

Embodiment 2

[0026] Weigh 50.00g of aluminum nitride, 1.02g of calcium oxide, 1.61g of yttrium oxide, 2.83g of PVB and 200ml of alcohol into a ball mill jar, mix evenly at a speed of 70 rpm, and put the suspension into a drying oven for drying. After grinding and sieving, take 1.5g of the mixture each time and mold it into a φ15 disc. Put the pattern into a tube furnace for degreasing under nitrogen atmosphere, raise the temperature to 450°C at a rate of 5°C / min, keep it warm for 3 hours and then cool down with the furnace to obtain an aluminum nitride green body. Put the green body into a graphite crucible and raise the temperature to 1450°C at a rate of 10°C / min, then keep it warm in flowing nitrogen for 5h for pre-sintering. Put the green body into a hot-pressed graphite mold, raise the temperature to 1650°C at a rate of 10°C / min, and then apply a pressure of 35MPa, and then cool it down to 1000°C at 10°C / min after holding for 1 hour. Then put it into a graphite furnace at 10°C / min and...

Embodiment 3

[0028] Weigh 50.00g of aluminum nitride, 1.02g of dysprosium oxide, 1.61g of yttrium oxide, 2.83g of PVB and 200ml of alcohol into a ball mill jar, mix evenly at a speed of 70 rpm, and put the suspension into a drying oven for drying. After grinding and sieving, take 1.5g of the mixture each time and mold it into a φ15 disc. Put the pattern into a tube furnace for degreasing under nitrogen atmosphere, raise the temperature to 450°C at a rate of 5°C / min, keep it warm for 3 hours and then cool down with the furnace to obtain an aluminum nitride green body. Put the green body into a graphite crucible and raise the temperature to 1550°C at a rate of 10°C / min, and then keep it in flowing nitrogen for 3h to carry out pre-sintering. Put the green body into a hot-pressed graphite mold, raise the temperature to 1700°C at a rate of 10°C / min, then apply a pressure of 25MPa, keep it for 2.5 hours, then cool it down to 1000°C at 10°C / min, and cool in the furnace. Then put it into a graphi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com