Environment-friendly grinding device

An environmental protection and grinding mechanism technology, applied in the direction of grinding drive device, grinding/polishing safety device, grinding machine, etc., can solve the problems of affecting the appearance, multiple grooves on the wall, and cleaning of broken stones, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

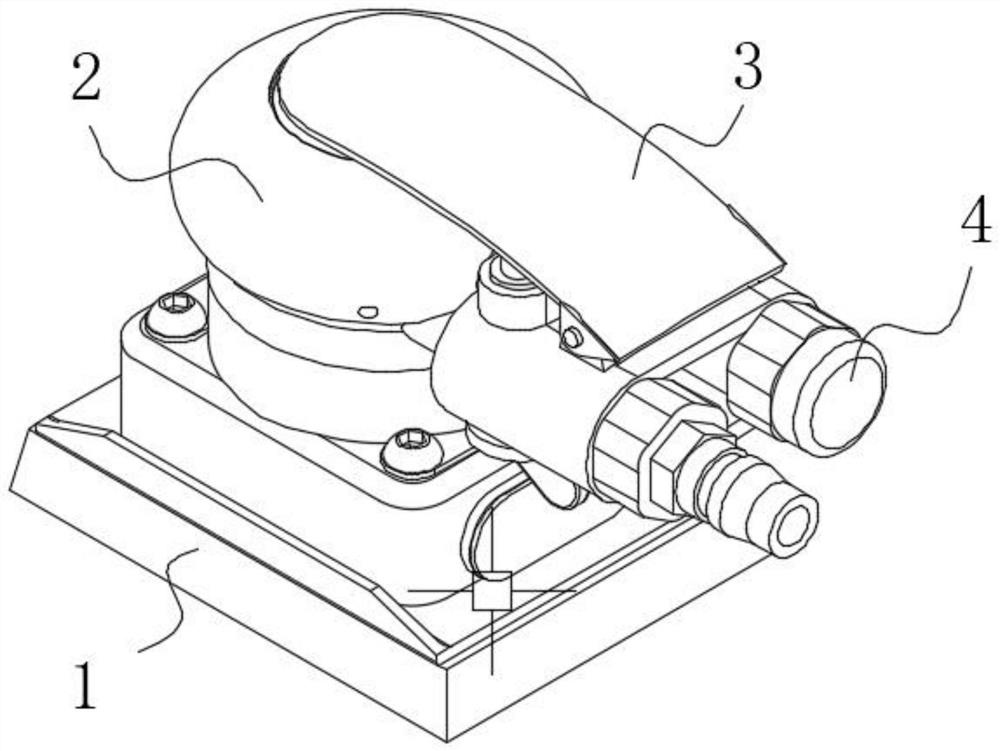

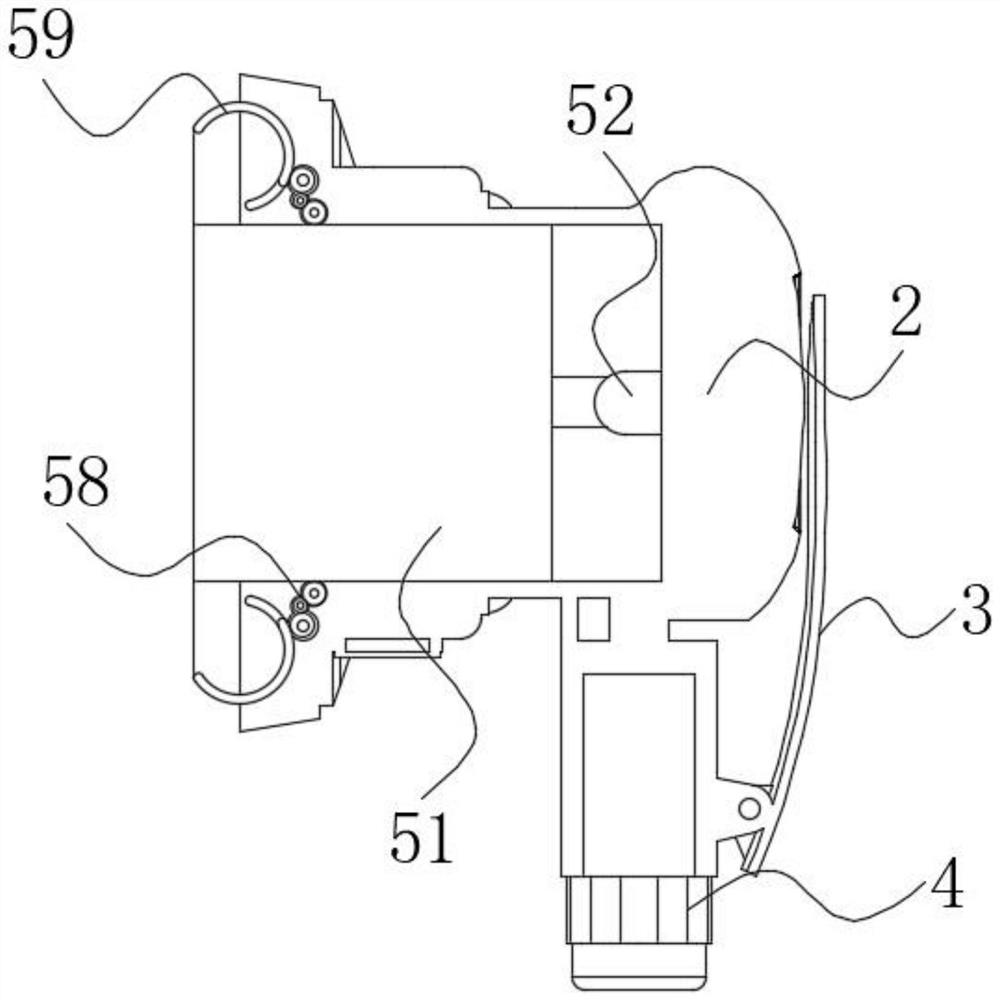

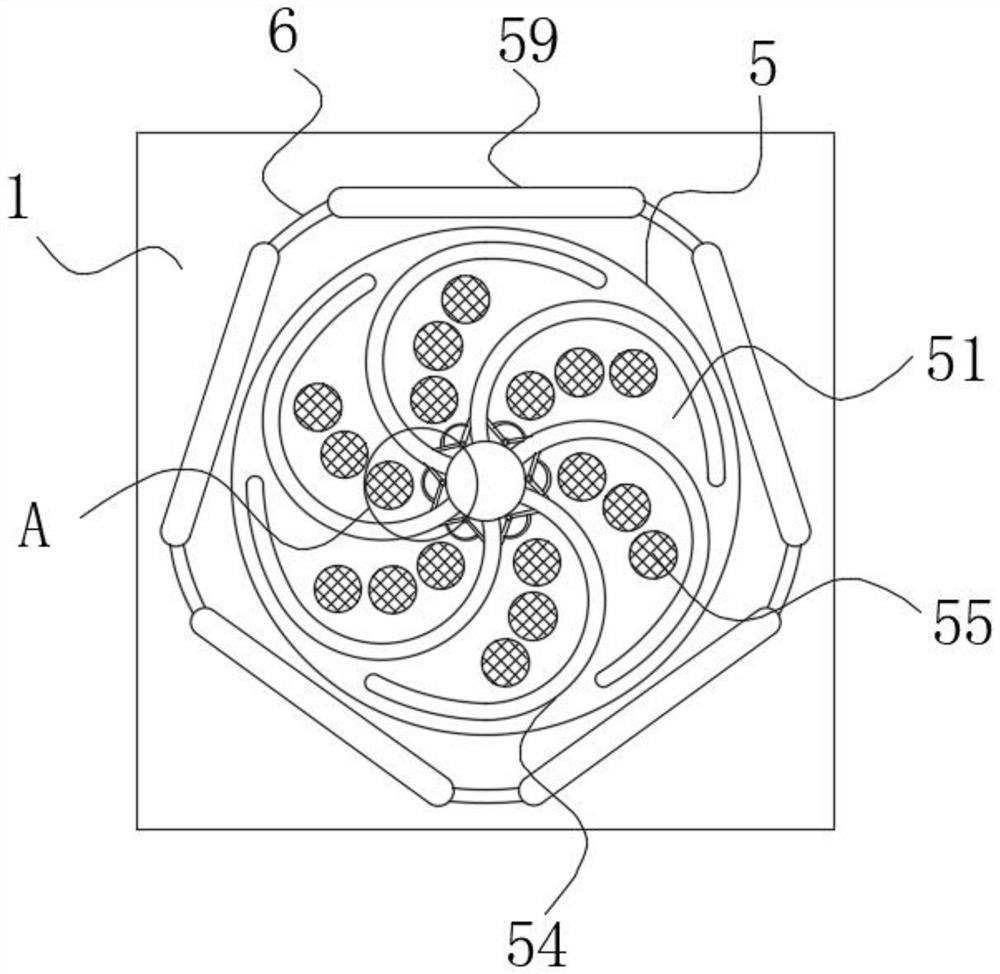

[0022] use Figure 1-Figure 6 An environmentally friendly grinding device according to an embodiment of the present invention will be described as follows.

[0023] Such as Figure 1-Figure 6As shown, a kind of environmental protection polishing device described in the present invention comprises installation block 1, motor 2, handle 3, suction joint 4 and polishing mechanism 5; The lower end of described installation block 1 is set to square, and the A motor 2 is fixedly installed inside the upper end, a suction joint 4 is fixedly installed on the right end of the installation block 1, and a grinding mechanism 5 is arranged inside the installation block 1; a handle 3 is fixedly connected to the outer end of the motor 2; the grinding mechanism 5 includes a rotating block 51, a telescopic rod 52, a mounting column 53, a scraper 54, a filter screen 55, a hinged plate 56, an expansion film 57, a gear set 58 and an arc plate 59; the inner end of the telescopic rod 52 is fixedly s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com