Traditional Chinese medicine bone peptide composition with function of improving bone joint health and preparation method of traditional Chinese medicine bone peptide composition

A composition, bone and joint technology, applied in drug combinations, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve problems such as harmful effects, drug dependence effects, and unclear curative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

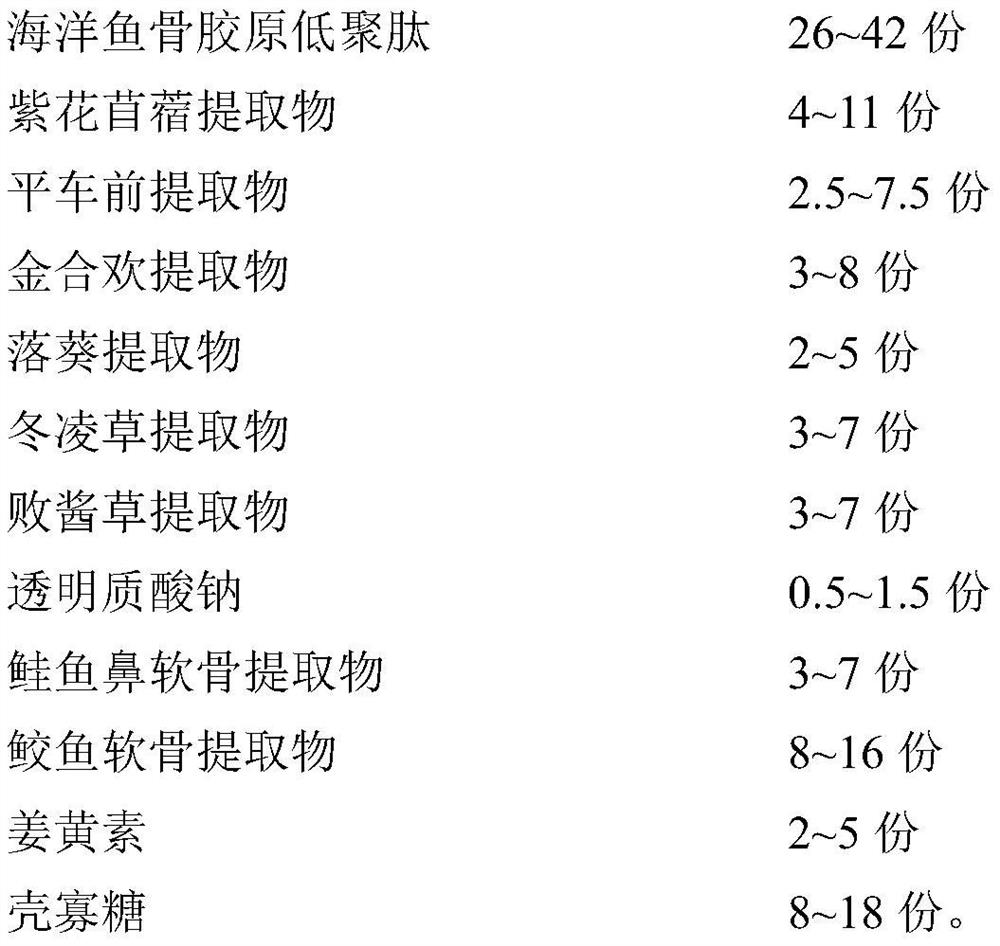

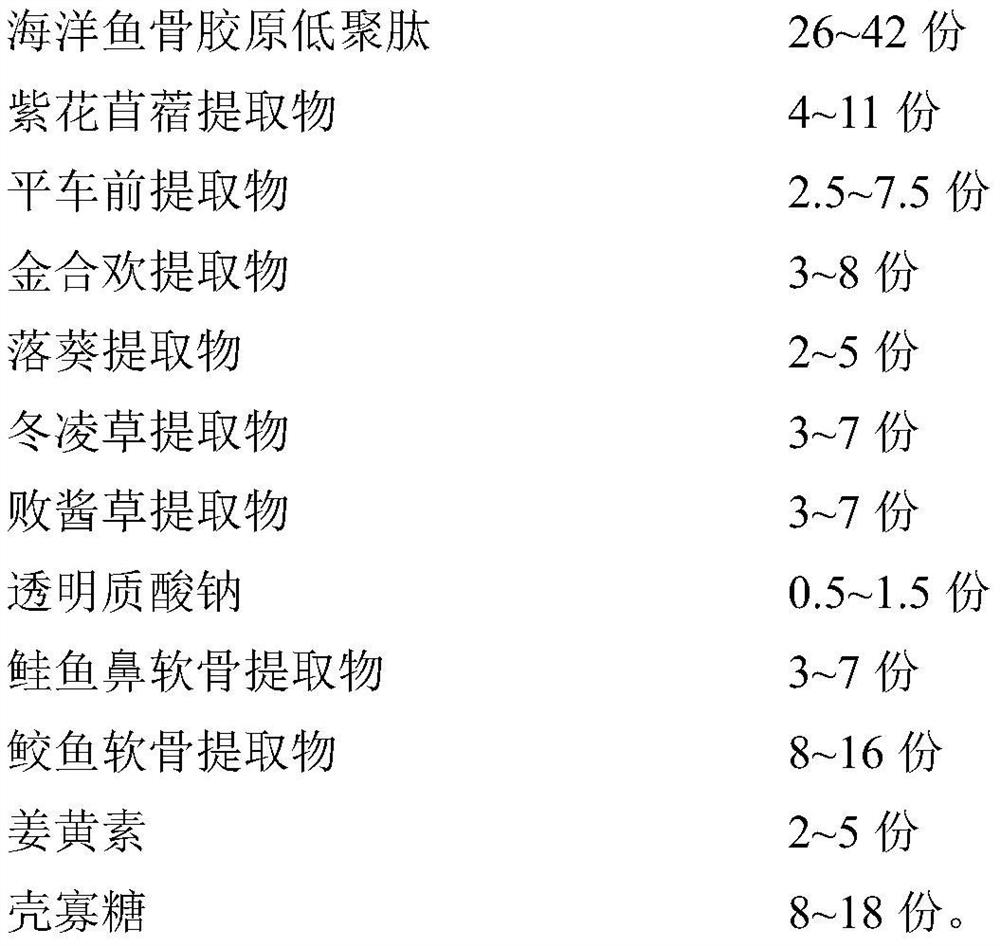

Method used

Image

Examples

Embodiment 1

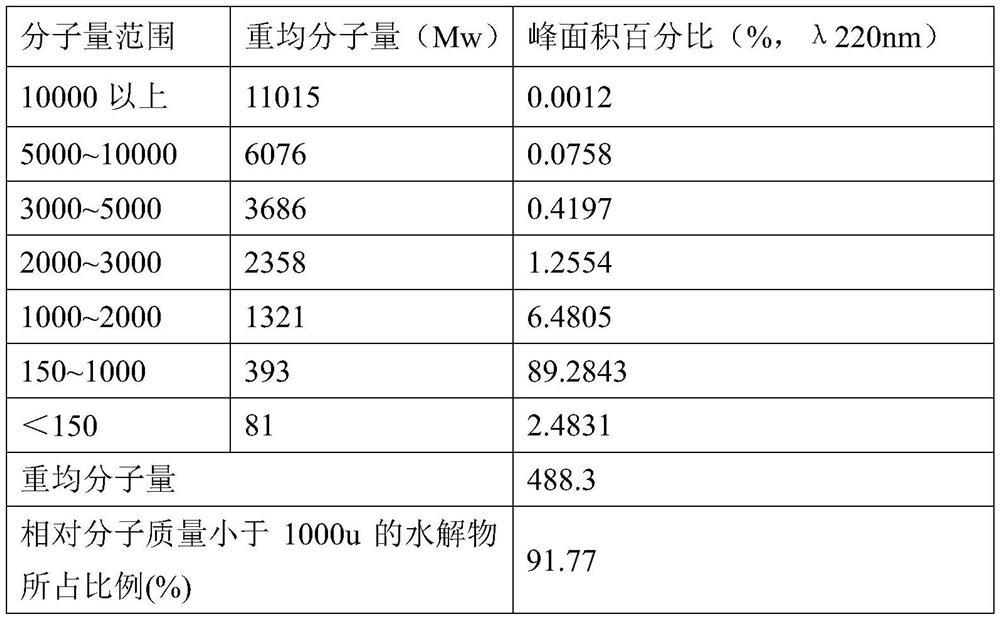

[0075] (1) The required marine fish bone collagen oligopeptide is obtained by pulverizing the marine fish bone, enzymatic hydrolysis, centrifugal filtration, concentration under reduced pressure and spray drying. The specific process is as follows:

[0076] (a) Grinding and mixing: crush the marine fish bone and pass through an 80-mesh sieve, add 12 times of pure water, mix the marine fish bone meal evenly, and disperse it in the aqueous solution to prepare a marine fish bone meal dispersion liquid to adjust the dispersion of the marine fish bone meal Solution pH to 8.0;

[0077] (b) Enzymolysis: heat and keep the temperature at 37°C, add trypsin and neutral protease into the marine fish bone powder dispersion, stir evenly for 1.5 hours, raise the temperature to 56°C, continue to stir for 2 hours, and trypsin The added amount of protease is 0.3wt% of the substrate content, and the added amount of neutral protease is 0.4wt% of the substrate content. After the enzymolysis is com...

Embodiment 2

[0102] (1) Crush marine fish bones and pass through a 100-mesh sieve, add pure water 20 times the weight of the material to prepare a dispersion, adjust the pH to 8.5, heat and keep at 37°C, add trypsin and neutral protease, and stir for 2.5 hours to enzymatically hydrolyze. Heat up to 52°C, continue enzymolysis for 2 hours to obtain an enzymolysis liquid, the amount of trypsin added is 0.35wt% of the substrate amount, the amount of neutral protease added is 0.25wt% of the substrate amount, and the enzyme is deactivated after the enzymolysis; enzymolysis The liquid was centrifuged at 12000rpm, the clear liquid was collected, and filtered through a microporous membrane with a thickness of 60μm, a pore size of 3μm, and a pressure of 0.1MPa to remove the filter residue; the filtrate was desalted and decolorized by ion exchange columns and activated carbon columns, and free Amino acids; the filtrate is concentrated under reduced pressure at a concentration temperature of 65°C and a...

Embodiment 3

[0107] (1) Crush marine fish bones and pass through a 60-mesh sieve, add pure water 10 times the weight of the material to prepare a dispersion, adjust the pH to 6.5, heat and keep it at 38°C, add trypsin and neutral protease, and stir for 1.5 hours to enzymatically hydrolyze. Heat up to 58°C, continue enzymolysis for 2.5 hours to obtain enzymolysis solution, the amount of trypsin added is 0.35wt% of the substrate amount, the amount of neutral protease added is 0.3wt% of the substrate amount, and the enzyme is extinguished after the end of the enzymolysis; The solution was centrifuged at 14000rpm, the clear liquid was collected, and filtered through a microporous membrane with a thickness of 90μm, a pore size of 5μm, and a pressure of 0.1MPa to remove the filter residue; the filtrate was desalted and decolorized by an ion exchange column and an activated carbon column, and removed Free amino acids; the filtrate was concentrated under reduced pressure at a concentration temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com