Preparation method of anti-tumor nano robot

A nano-robot and anti-tumor technology, which is applied in the field of preparation of anti-tumor nano-robots, can solve the problems that affect the application of tumor treatment, high impurity content, and large particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing an anti-tumor nanorobot, comprising the following steps:

[0026] a) The iron target is placed in the sputtering chamber, feed argon and oxygen into the sputtering chamber, start the sputtering chamber power supply and carry out magnetron sputtering; in the process of magnetron sputtering, the cavity temperature of the sputtering chamber 800~1200℃;

[0027] b) After the magnetron sputtering is finished, maintain the cavity temperature of the sputtering chamber at 800-1200°C, and feed acetylene gas into the sputtering chamber;

[0028] c) After passing the acetylene gas, pass the protective gas into the sputtering chamber, and reduce the cavity temperature of the sputtering chamber to 100-300° C. within 5-15 minutes to obtain an anti-tumor nanorobot.

[0029] In the preparation method provided by the present invention, an iron target is first placed in a sputtering chamber. Among them, the iron target is preferably iron oxi...

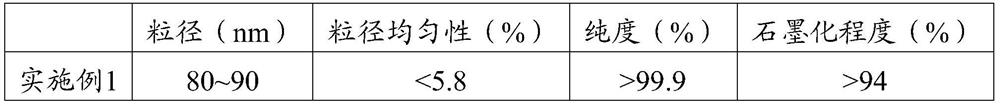

Embodiment 1

[0038] The preparation of anti-tumor nanorobots comprises the following steps:

[0039] 1) Cleaning: First wipe the glass workpiece fixture with alcohol, then put it into an ultrasonic cleaner, super-wash with deionized water, and super-clean with alcohol, and finally put the workpiece fixture in alcohol steam for drying. When the workpiece fixture is cleaned by steam When taken out, the workpiece holder can be dried quickly because the condensed steam evaporates from the surface;

[0040] 2) Paste the protective film: paste the cleaned workpiece fixture with polyethylene film to protect the cleanliness of the workpiece fixture and protect the workpiece fixture from damage;

[0041] 3) Install the film-attached workpiece fixture on the running track of the magnetron sputtering device, and tear off the protective film before entering the film feeding chamber;

[0042] 4) The working fixture moves to the film feeding chamber of the magnetron sputtering device, then closes the v...

Embodiment 2

[0050] The preparation of anti-tumor nanorobots comprises the following steps:

[0051] 1) Cleaning: First wipe the glass workpiece fixture with alcohol, then put it into an ultrasonic cleaner, super-wash with deionized water, and super-clean with alcohol, and finally put the workpiece fixture in alcohol steam for drying. When the workpiece fixture is cleaned by steam When taken out, the workpiece holder can be dried quickly because the condensed steam evaporates from the surface;

[0052] 2) Paste the protective film: paste the cleaned workpiece fixture with polyethylene film to protect the cleanliness of the workpiece fixture and protect the workpiece fixture from damage;

[0053] 3) Install the film-attached workpiece fixture on the running track of the magnetron sputtering device, and tear off the protective film before entering the film feeding chamber;

[0054] 4) The working fixture moves to the film feeding chamber of the magnetron sputtering device, then closes the v...

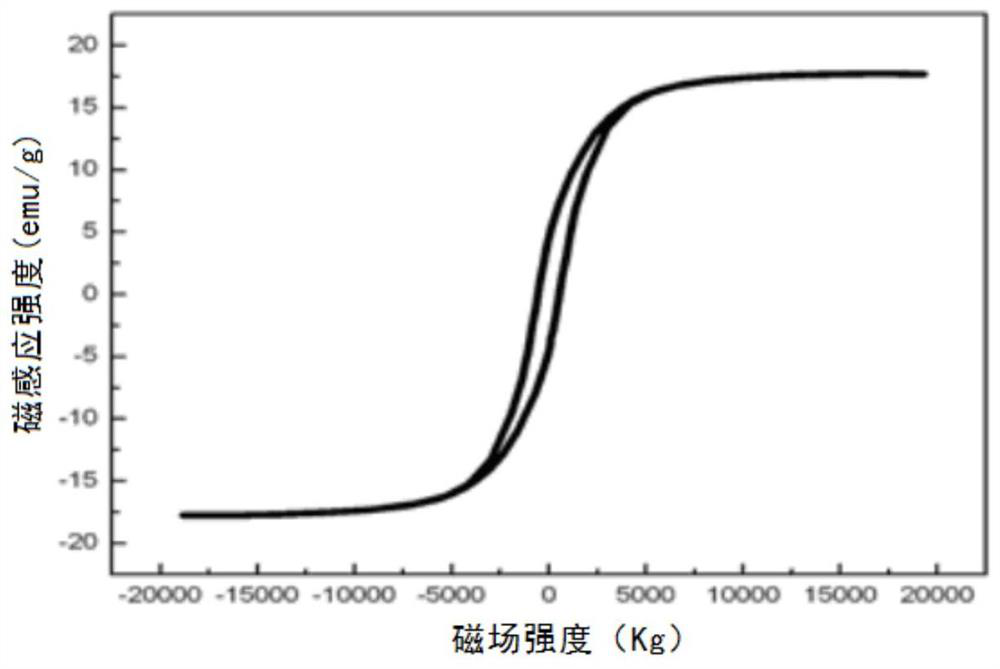

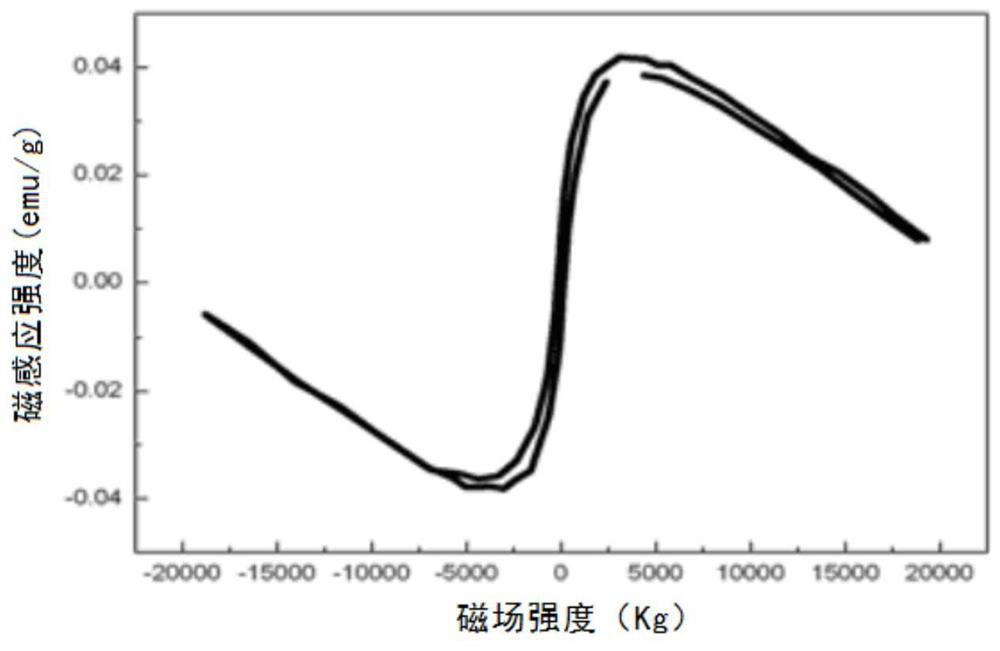

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Residual magnetization | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com