Filling material formed by recycling non-metal powder of waste circuit boards and preparation method of filling material

A technology for waste circuit boards and fillers, which is applied to the field of fillers formed by recycling waste circuit board non-metallic powders and its preparation, and can solve the problems of diversity and low cost of recycling non-metallic powders of waste electronic circuit boards that have not been proposed. problem, to achieve the effect of reducing product cost, simple preparation process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

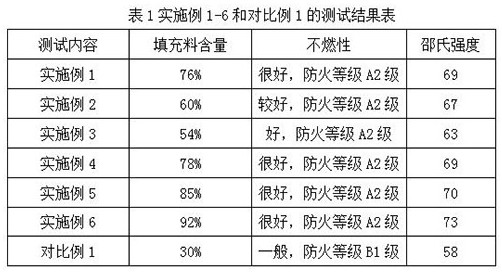

Examples

Embodiment 1

[0035] A filler for recycling waste circuit board non-metal powder, which consists of the following components by weight: 30% solid plastic, 60% 20-mesh waste circuit board non-metal powder, 10% processing aids, of which solid The plastic is PE, the diameter is less than 5mm, and the processing aids are 2% lubricant, 3% stabilizer, 3% compatibilizer, and 2% toner.

Embodiment 2

[0037] A filler for recycling waste circuit board non-metal powder, which consists of the following components by weight: 64% solid plastic, 27.7% 20-mesh waste circuit board non-metal powder, 8.3% processing aids, of which solid The plastic is waste PVC, and the processing aids are 2% lubricant, 2% stabilizer, 2% compatibilizer, 2% toner, and 0.3% titanate coupling agent.

Embodiment 3

[0039] A filler for recycling waste circuit board non-metal powder, which consists of the following components by weight: 45% solid plastic, 46% 20-mesh waste circuit board non-metal powder, 9% processing aids, of which solid The plastic is waste PA, and the processing aids are 2% lubricant, 2% stabilizer, 2% compatibilizer, 2% toner, and 1% titanate coupling agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com