Preparation method of bionic inspired polyurethane elastomer with super toughness, super stretching, self-repairing and high resilience

A polyurethane elastomer and self-repairing technology, which is applied in the preparation of super-stretch and self-repairing high-resilience polyurethane elastomer. The effects of mechanical properties, excellent resilience, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a bionic-inspired super-tough, super-stretchable and self-repairing high-resilience polyurethane elastomer, comprising the following steps:

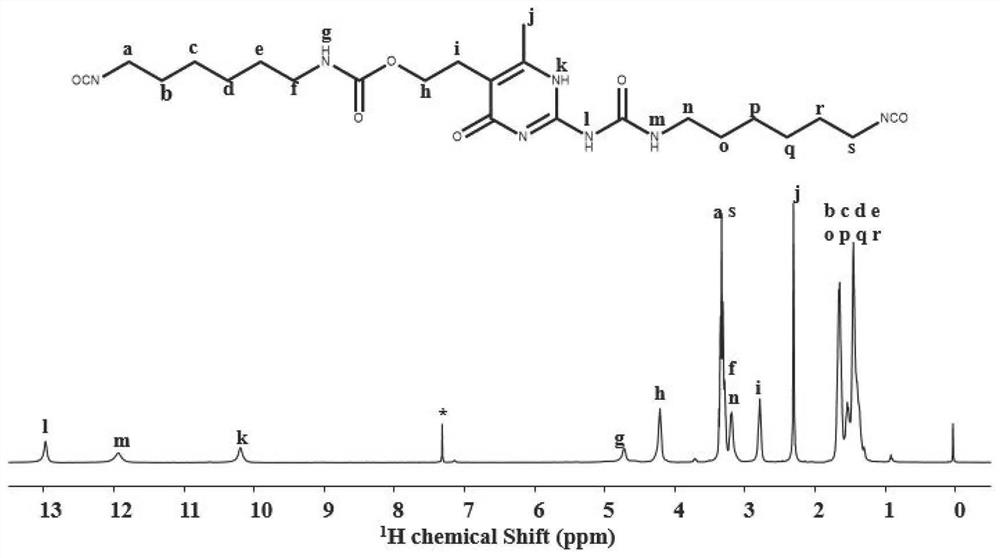

[0028] Step 1) Synthesis of Multiple Hydrogen Bond Monomer (HDI-UPy-HDI)

[0029] Step 1.1) Synthesis of multiple hydrogen bond precursors: 5.12g of 2-acetylbutyrolactone, 3.6g of guanidine carbonate and 11ml of triethylamine were dissolved in 40ml of absolute ethanol, and refluxed at 100°C for 1 hour. The mixture gradually became clear from turbidity, and the reaction was continued for 3 hours. After the reaction, the mixture was filtered to obtain a precipitate, washed three times with ethanol, and finally dried in a vacuum oven at room temperature for 24 hours to obtain a white powder solid that is a multiple hydrogen bond precursor.

[0030] Step 1.2) Add 0.85g of the precursor obtained from the above reaction, 14ml of 1,6-hexamethylene diisocyanate (HDI) and 1ml of pyridine to a 100ml round bottom flas...

Embodiment 2

[0035] A method for preparing a bionic-inspired super-tough, super-stretchable and self-repairing high-resilience polyurethane elastomer, comprising the following steps:

[0036] Step 1) Synthesis of Multiple Hydrogen Bond Monomer (HDI-UPy-HDI)

[0037] Step 1.1) Synthesis of multiple hydrogen bond precursors: 5.12g of 2-acetylbutyrolactone, 3.6g of guanidine carbonate and 11ml of triethylamine were dissolved in 40ml of absolute ethanol, and refluxed at 95°C for 1 hour. The mixture gradually became clear from turbidity, and the reaction was continued for 3 hours. After the reaction, the mixture was filtered to obtain a precipitate, washed three times with ethanol, and finally dried in a vacuum oven at room temperature for 24 hours to obtain a white powder solid that is a multiple hydrogen bond precursor.

[0038] Step 1.2) Add 0.85g of the precursor obtained from the above reaction, 14ml of 1,6-hexamethylene diisocyanate (HDI) and 1ml of pyridine to a 100ml round bottom flask...

Embodiment 3

[0043] A method for preparing a bionic-inspired super-tough, super-stretchable and self-repairing high-resilience polyurethane elastomer, comprising the following steps:

[0044] Step 1) Synthesis of Multiple Hydrogen Bond Monomer (HDI-UPy-HDI)

[0045] Step 1.1) Synthesis of multiple hydrogen bond precursors: 5.12g of 2-acetylbutyrolactone, 3.6g of guanidine carbonate and 11ml of triethylamine were dissolved in 40ml of absolute ethanol, and refluxed at 100°C for 1 hour. The mixture gradually became clear from turbidity, and the reaction was continued for 3 hours. After the reaction, the mixture was filtered to obtain a precipitate, washed three times with ethanol, and finally dried in a vacuum oven at room temperature for 24 hours to obtain a white powder solid that is a multiple hydrogen bond precursor.

[0046] Step 1.2) Add 0.85g of the precursor obtained from the above reaction, 14ml of 1,6-hexamethylene diisocyanate (HDI) and 1ml of pyridine to a 100ml round bottom flas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com