Cement-based capillary crystalline waterproof material

A osmotic crystalline waterproof and cement-based technology, applied in the field of building materials, can solve the problems of poor compressive and flexural properties, impermeability and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: The performance of the waterproof material of the present invention is shown in Table 1.

[0027] Table 1: Properties of waterproof materials

[0028] serial number Material properties illustrate 1 Withstand strong water pressure for a long time The test proves that the maximum water pressure can reach 12.3Mpa. 2 penetration depth The penetration depth of the chemical reaction reaches 30cm. 3 service life The service life is synchronized with the concrete. 4 self-healing ability When the crack width is less than or equal to 0.4mm, it can heal itself. 5 Good ventilation It can block water but not block air, and does not affect the breathing of concrete. 6 High temperature resistance, oxidation resistance, carbonization resistance It can work normally at -32℃~-130℃. 7 Corrosion resistance, freeze-thaw resistance When used, it will not be damaged when the pH is between 3 and 11; it can resist...

Embodiment 2

[0030] Embodiment 2: The present invention can be used as a waterproof repair paint. In this embodiment, the waterproof material of the present invention is used to smear and repair the cracks in the sewage pool.

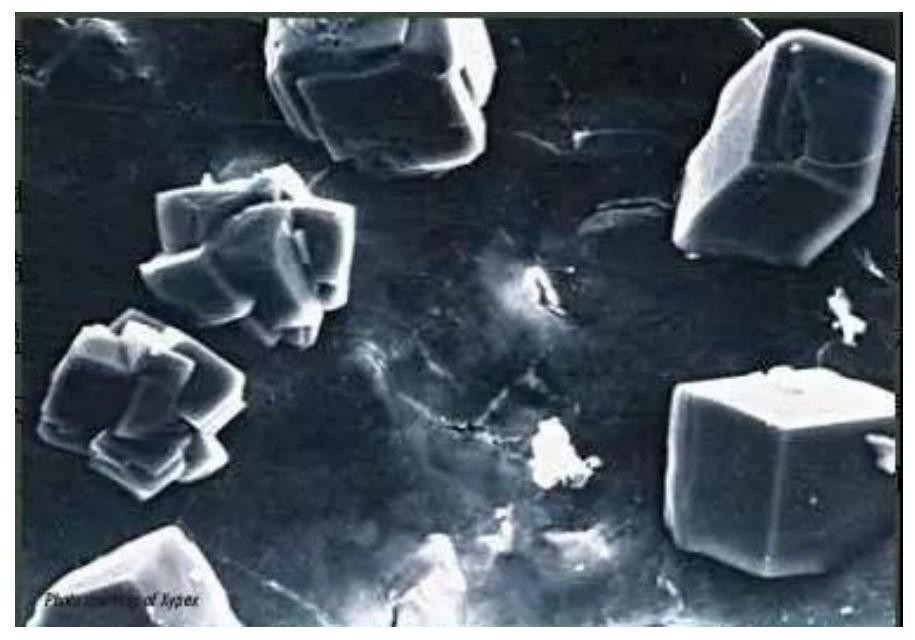

[0031] Wherein the waterproof material of the present invention The active chemical substance in the waterproof material of the present invention has stronger permeability, can use water as the carrier to infiltrate and diffuse deeply into the internal pores of cement concrete, and chemically react with calcium ions in the concrete, Generate water-insoluble calcium silicate hydrate (dendritic crystals), the crystals are filled with capillary pores and integrated with the concrete, blocking the capillary channels inside the concrete, thereby making the concrete dense, preventing water penetration, and has good anti-penetration and self-repairing functions .

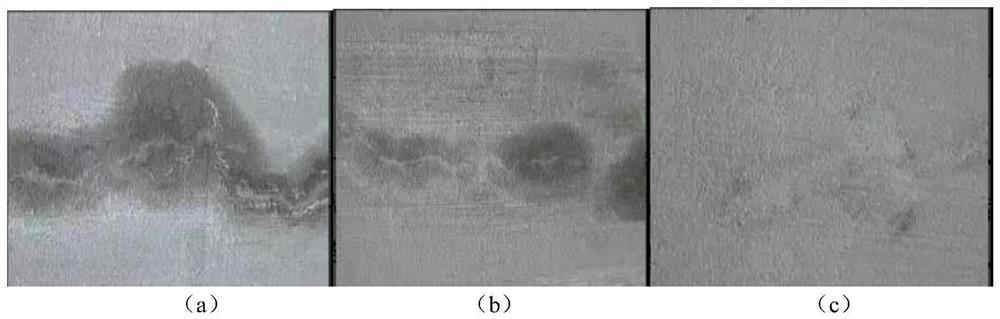

[0032] figure 1 For the concrete that has not been processed by the present invention, the surface layer of ...

Embodiment 3

[0035] Embodiment 3: The present invention can be used as repairing material to handle the crack of concrete

[0036] The waterproof material of the present invention adopts different construction methods for different cracks.

[0037](1) Treatment of concrete cracks less than 0.4mm wide

[0038] For cracks smaller than 0.4mm, when there is water flow in the crack, plug the leak first, then clean the surface of the crack, and directly apply two layers of the waterproof material of the present invention, wherein the waterproof material and water are in a volume ratio of 5:2 Dubbed as paint. After the coating is in a semi-dry state, continue curing for 72 hours. In hot or dry weather, spray water several times to strengthen maintenance and prevent premature drying of the coating. Within 48 hours after construction, avoid sun exposure, rain, frost, sewage and low temperature below 4°C. It is better to cover with wet straw bags for open-air construction.

[0039] (2) Treatment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com