Preparation method of composite coated ternary positive electrode material

A technology of positive electrode materials and ternary materials, which is applied in the field of preparation of composite coated ternary positive electrode materials, can solve the problems of poor conductivity of positive electrode materials, achieve the effects of improving rate performance, protecting interfaces, and improving ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The present invention provides the following technical scheme: a method for preparing a composite coated lithium-ion battery ternary material, the specific process steps are as follows:

[0025] The ternary precursor Ni 0.8 co 0.15 mn 0.05 (OH) 2 Mix it with lithium hydroxide, where Li / Me=1.05, mix it with a high-speed mixer for 10 minutes, and then burn it at 800°C for 15 hours to obtain a nickel-cobalt-manganese ternary material. The obtained nickel-cobalt-manganese ternary material and Al(OH) 3 mixed, where Al(OH) 3 The molar ratio is 0.5mol%, and it is sintered at 550°C for 11 hours to obtain an oxidized coated ternary material. Coating ternary materials and LiAlO with oxide type 2 mixed, where LiAlO 2 The molar ratio is 0.2mol%, and it is sintered at 500°C for 10h to obtain a composite coated ternary material.

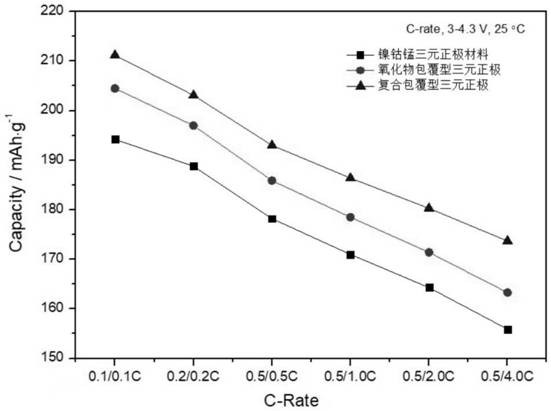

[0026] The nickel-cobalt-manganese ternary materials, oxide-coated ternary materials and composite-coated ternary materials prepared in this exampl...

Embodiment 2

[0028] The present invention provides the following technical scheme: a method for preparing a composite coated lithium-ion battery ternary material, the specific process steps are as follows:

[0029] The ternary precursor Ni 0.83 co 0.1 mn 0.07 (OH) 2 Mix it with lithium hydroxide, where Li / Me=1.06, mix it with a high-speed mixer for 15 minutes, and then burn it at 805°C for 14 hours to obtain a nickel-cobalt-manganese ternary material. The obtained nickel-cobalt-manganese ternary material and Mg(OH) 2 mixed, where, Mg(OH) 2 The molar ratio is 0.5mol%, and sintered at 550°C for 12h to obtain an oxidized coated ternary material. Mix the oxidized coated ternary material with LiAlO2, where LiAlO 2 The molar ratio is 0.3mol%, and it is sintered at 500°C for 10h to obtain a composite coated ternary material.

Embodiment 3

[0031] The present invention provides the following technical scheme: a method for preparing a composite coated lithium-ion battery ternary material, the specific process steps are as follows:

[0032] The ternary precursor Ni 0.88 co 0.09 mn 0.03 (OH) 2 Mix it with lithium hydroxide, where Li / Me=1.06, mix it with a high-speed mixer for 15 minutes, and then burn it at 805°C for 14 hours to obtain a nickel-cobalt-manganese ternary material. The resulting nickel-cobalt-manganese ternary material and Zr(OH) 4 mixed, among them, Zr(OH) 4 The molar ratio of is 1mol%, and it is sintered at 600°C for 11h to obtain an oxidized coated ternary material. Coating ternary materials and LiZrO 2 mixed, where LiZrO 2 The molar ratio is 0.1mol%, and it is sintered at 450°C for 10h to obtain a composite coated ternary material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com