Laser additive repairing method for surface defects of alloy steel rail

A laser additive and repair method technology, applied in the direction of additive processing, additive manufacturing, etc., can solve the problems of prone to wear or damage, frog failure, etc., and achieve the effects of small deformation, crack prevention, and reduced heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions in the embodiments of the present invention will be described below with reference to the drawings in the embodiments of the present invention.

[0033] The invention provides a technical proposal of a laser additive repair method suitable for surface defects of alloy steel rails, and the specifically selected alloy steel rails are fixed frog core rails.

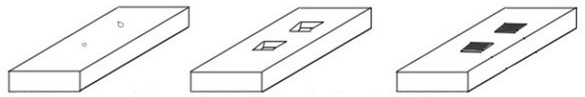

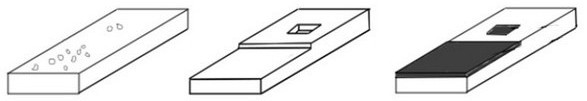

[0034] like figure 1 As shown, the repair method in the present invention is specifically realized through the following steps:

[0035] First of all, quantitatively evaluate the damage degree of the fixed frog core rail as the basis for the judgment of the repair feasibility and the selection of the repair plan (see Figure 2). Specifically, for the single damage of the fixed frog core rail , first calculate and judge whether the ratio of the maximum depth of the area to be repaired and the theoretical thickness of the part in the direction of the maximum depth does not exceed 1 / 3; at the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com