Polypyrrole coated MoS2/C composite material and preparation method thereof

A technology of composite materials and polypyrrole, which is applied in the direction of nanotechnology for materials and surface science, active material electrodes, nanotechnology, etc., can solve problems such as complex process and insufficient environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

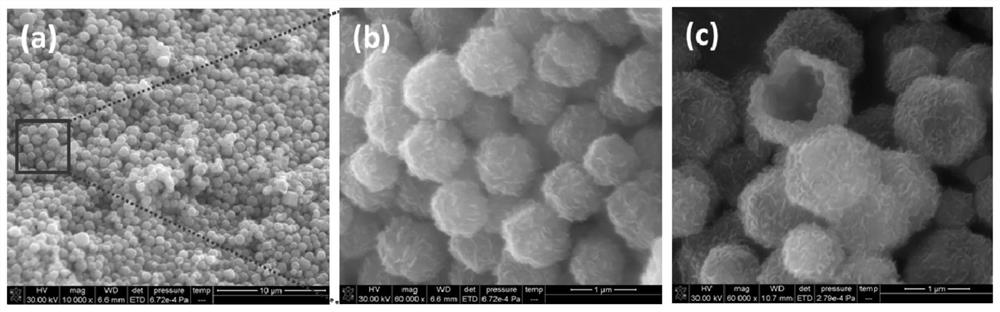

[0035] 1) Prepared from MoS 2 / C assembled hollow nanospheres: Weigh 0.24g sodium molybdate dihydrate and 0.18g thiourea and dissolve them in 40mL ethanol, add 0.1g polyvinylpyrrolidone (average molecular weight is 8000), stir for 12h (the system is a milky white suspension ) and then transferred to a 100 ml polytetrafluoroethylene liner, sealed the liner and placed it in an autoclave, heated to 230° C. to keep the reaction for 42 hours. After the autoclave was cooled, the hollow nanospheres were collected, washed alternately with ethanol and deionized water for 5 times, then dried in a vacuum oven at 70 °C for 12 h, and annealed at 800 °C for 2 hours in argon to obtain MoS 2 / C assembled hollow nanospheres. The resulting MoS was characterized by scanning electron microscopy 2 / C assembled hollow nanosphere surface morphology, such as figure 1 shown. Among them, such as figure 1 As shown in (a) and 1(b), the prepared MoS 2 The / C hollow nanosphere has a uniform size, the...

Embodiment 2

[0054] Repeat Example 1, the difference is:

[0055] In step 1), the amount of ethanol was changed to 50mL, the amount of polyvinylpyrrolidone was changed to 0.024g, and the reaction was changed to 200°C for 30h of heat preservation;

[0056] In step 2), FeCl 3 The dosage is changed by MoS 2 / C 5% of the mass of the assembled hollow nanospheres.

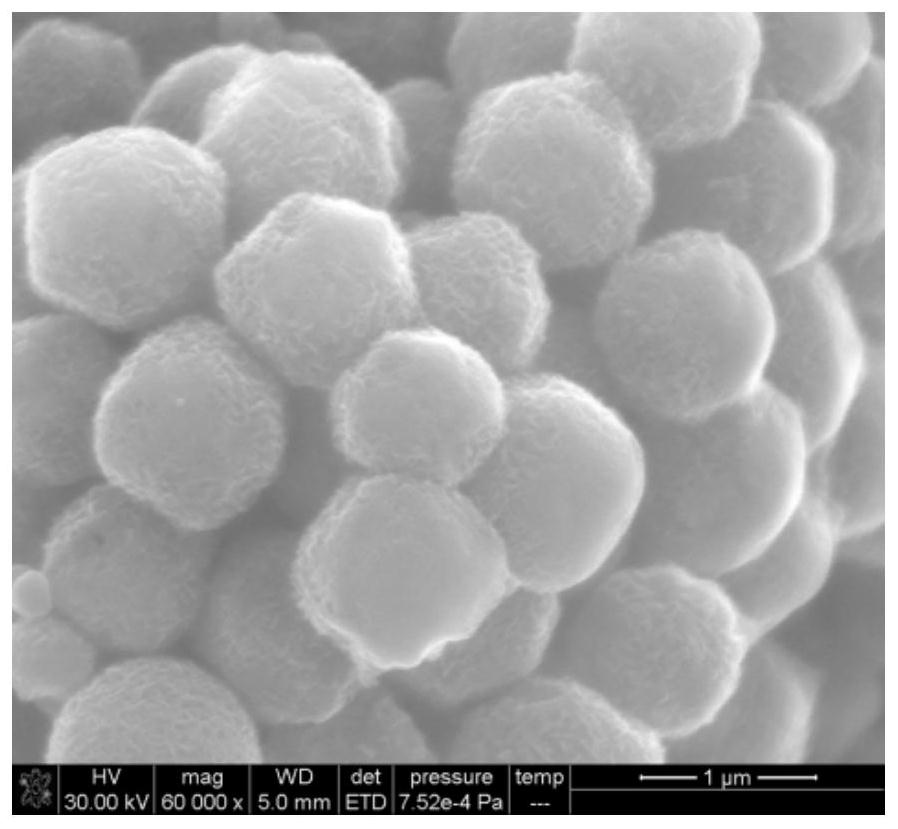

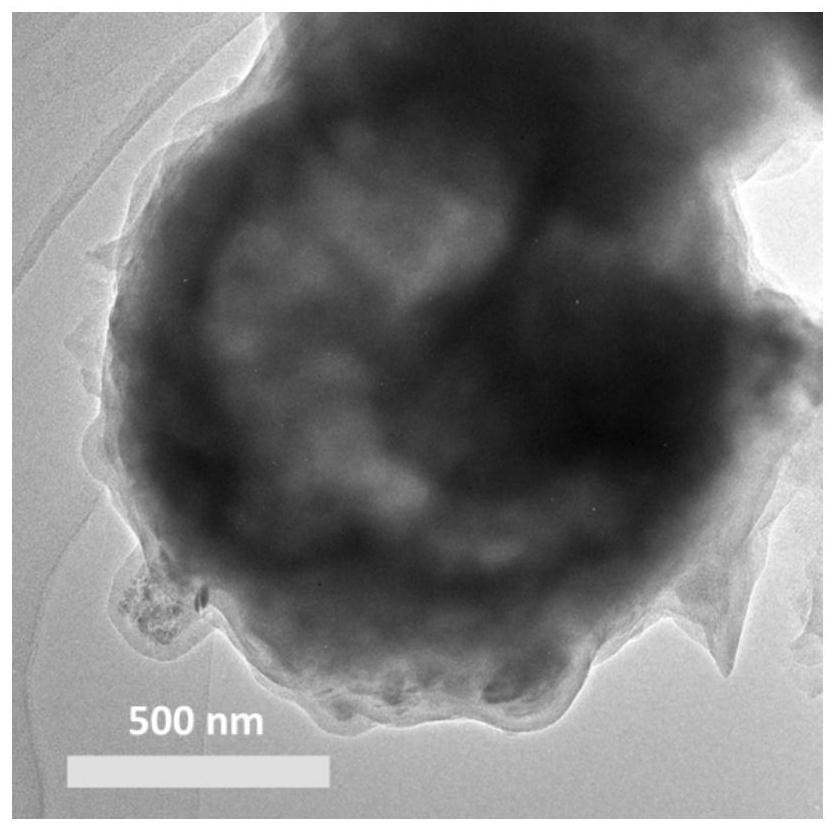

[0057] The resulting composite material was characterized by scanning electron microscopy and transmission electron microscopy, and it was determined to be polypyrrole-coated MoS with a hollow spherical structure. 2 / C Composite.

Embodiment 3

[0059] Repeat Example 1, the difference is:

[0060] In step 1), polyvinylpyrrolidone with an average molecular weight of 10,000 is used instead of polyvinylpyrrolidone with an average molecular weight of 8,000, and the reaction is changed to 150°C for 50 hours of heat preservation;

[0061] In step 2), FeCl 3 The dosage is changed by MoS 2 15% of the mass of the assembled hollow nanospheres at / C, the reaction was changed to 60° C. for 5 h.

[0062] The resulting composite material was characterized by scanning electron microscopy and transmission electron microscopy, and it was determined to be polypyrrole-coated MoS with a hollow spherical structure. 2 / C Composite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com