Al-Ga-In-Sn-Cu alloy for hydrogen production, preparation method of Al-Ga-In-Sn-Cu alloy and application to fuel cells

An al-ga-in-sn, fuel cell technology, applied in the field of aluminum alloy hydrogen production, can solve the problems of unsatisfactory hydrogen production performance, large demand for metal In, insufficient transportation and storage, etc., to reduce energy consumption, The effect of reducing production costs and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0035]Preparation of Al-Ga-In-Sn-Cu Alloy

[0036] (1) The alloy composition is shown in Table 1:

[0037] The alloy element composition mass percent (wt%) of table 1 embodiment 1-4

[0038]

[0039] (2) Preparation process:

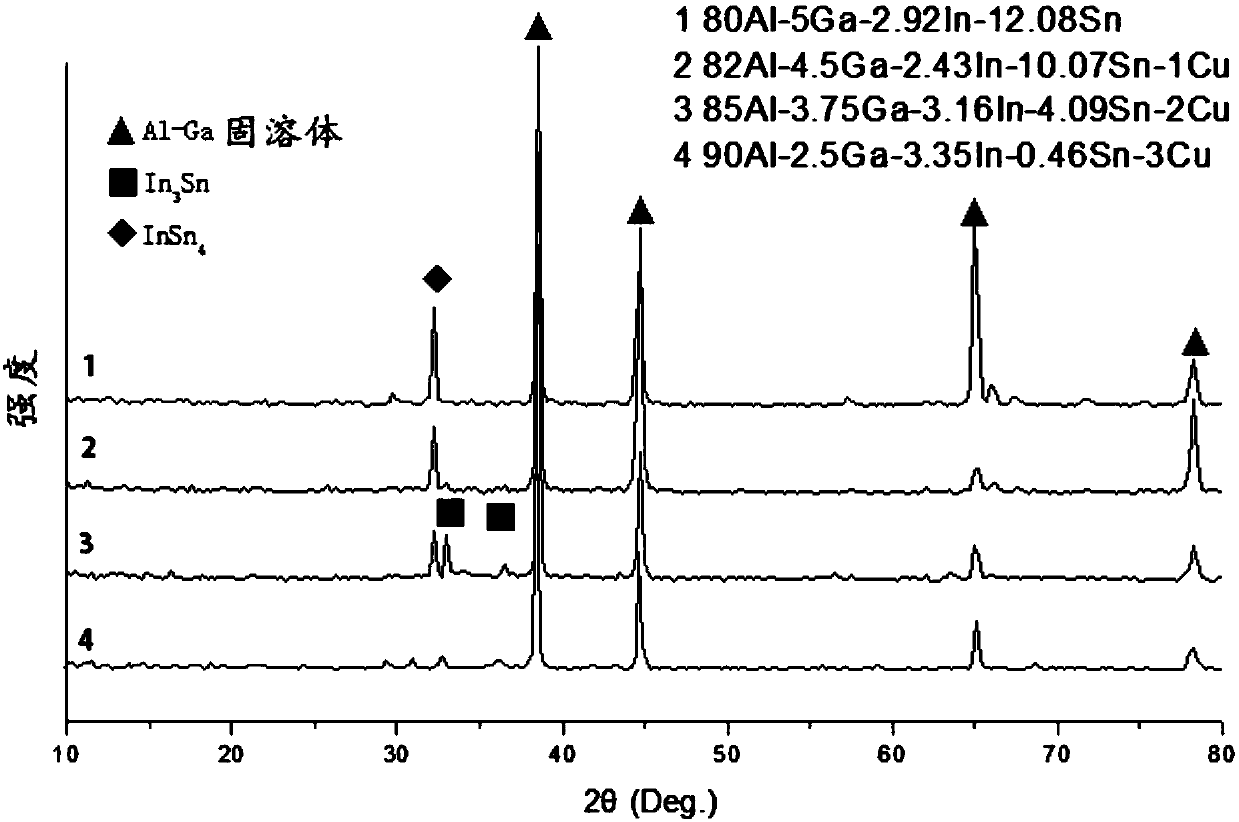

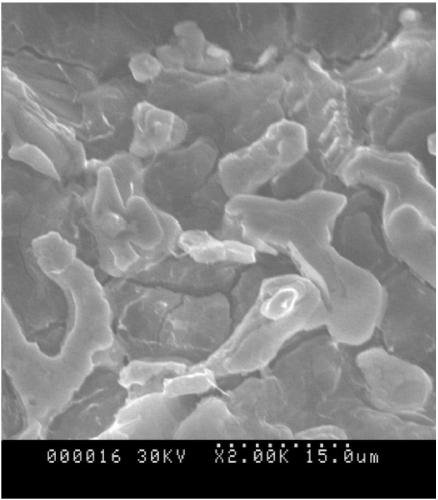

[0040] The purity of the raw material is ≥99wt%, and the weighed metal is placed in a high-temperature furnace under the protection of nitrogen, sintered at 800°C, and kept at 800°C for one hour. Stir and cast after heat preservation, cool under natural conditions after casting, and pack after cooling. For its XRD and SEM characterization, see figure 1 with 3 .

[0041] (3) Hydrogen production index:

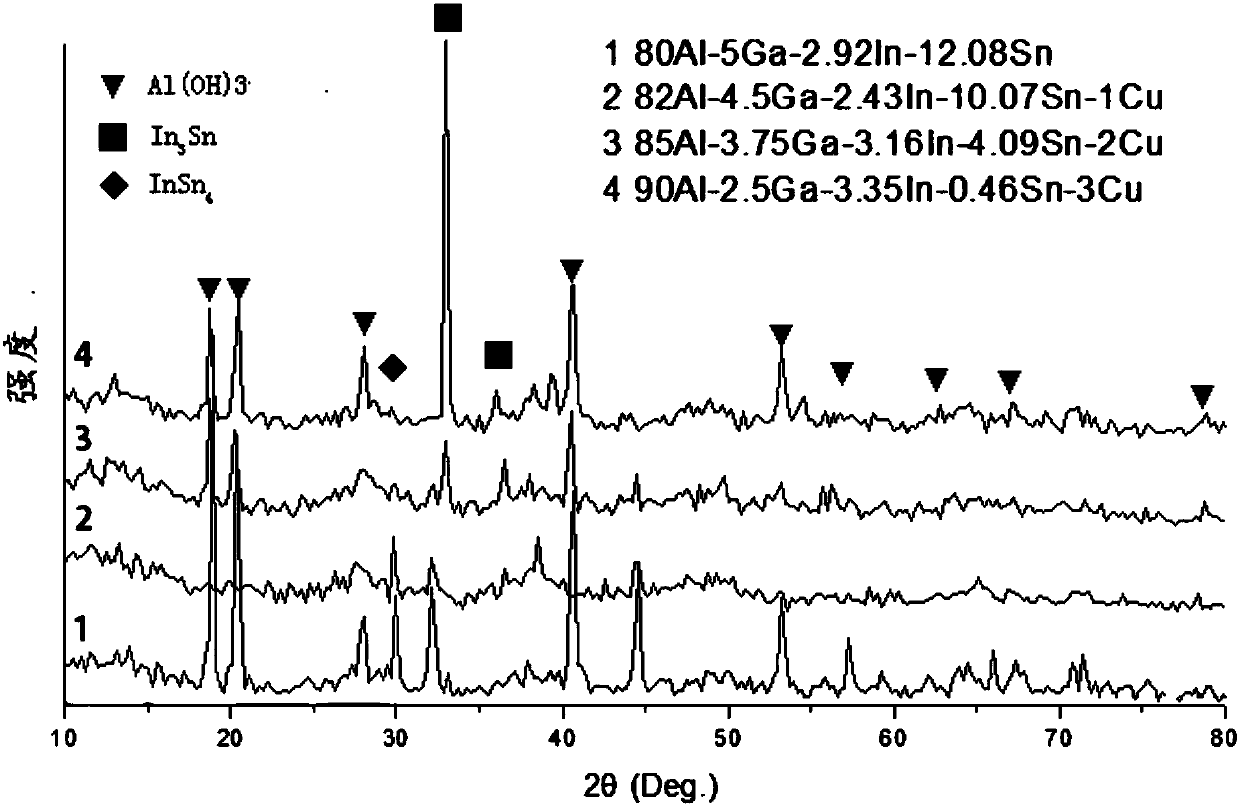

[0042] The alloys prepared in Examples 1-4 were reacted violently in water at 40° C. to generate a large amount of hydrogen, and the amount of hydrogen produced is shown in Table 2. The XRD characterization of the alloy residue after hydrogen production is shown in figure 2 .

[0043] Table 2 The amount of hydrogen produced by the aluminum all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com