266-nanometer high-power laser antireflection film and preparation method thereof

A high-power, anti-reflection coating technology, used in optics, optical components, instruments, etc., can solve the problems of short life, low transmittance, and low light damage threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

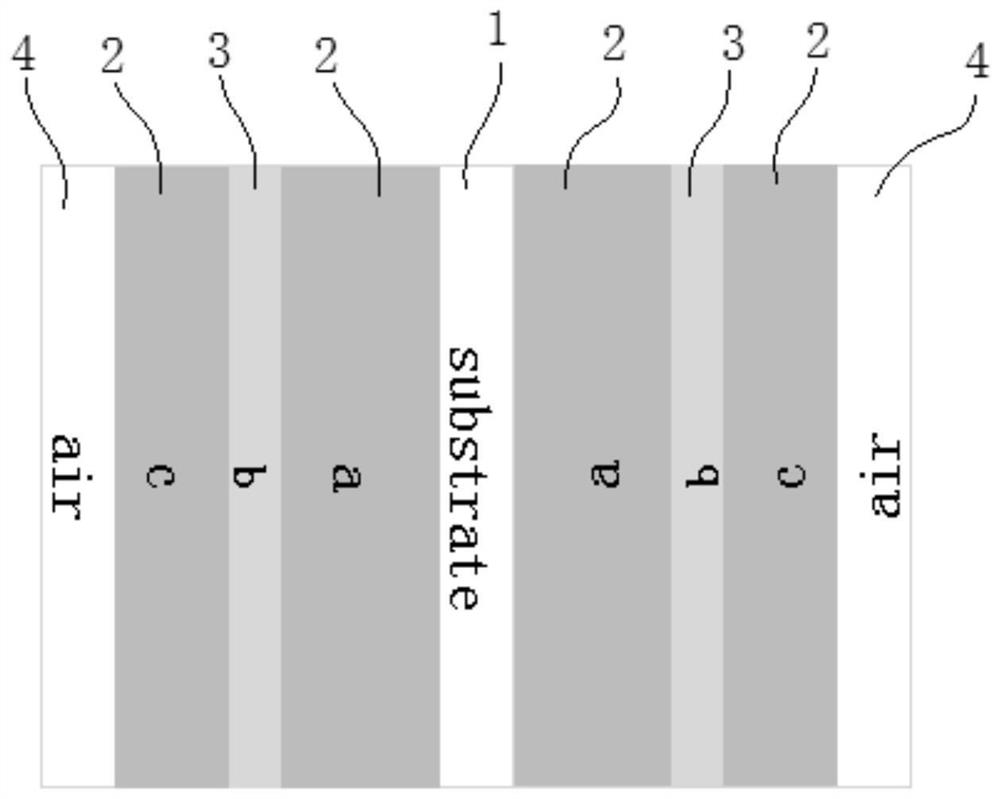

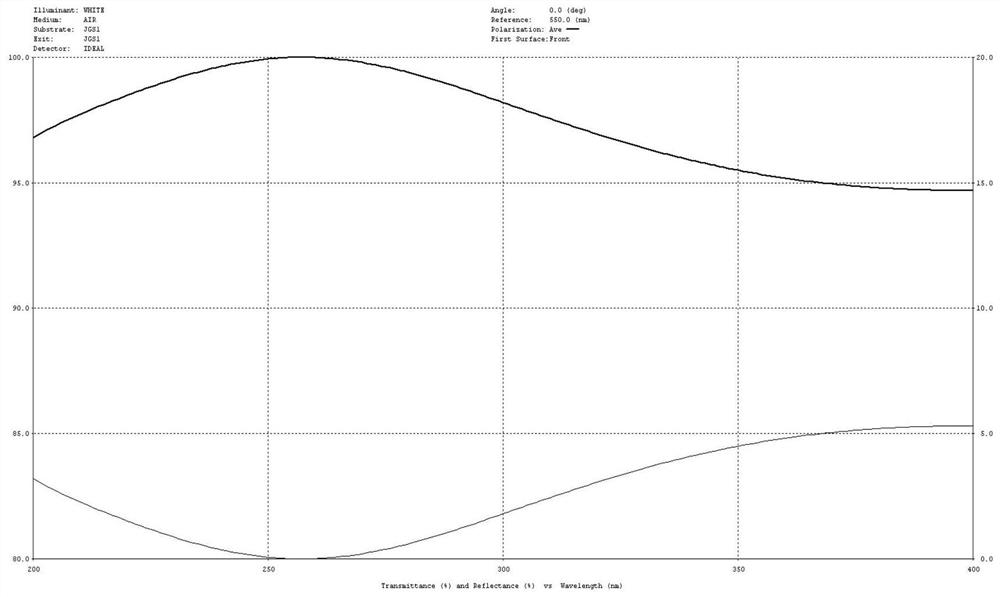

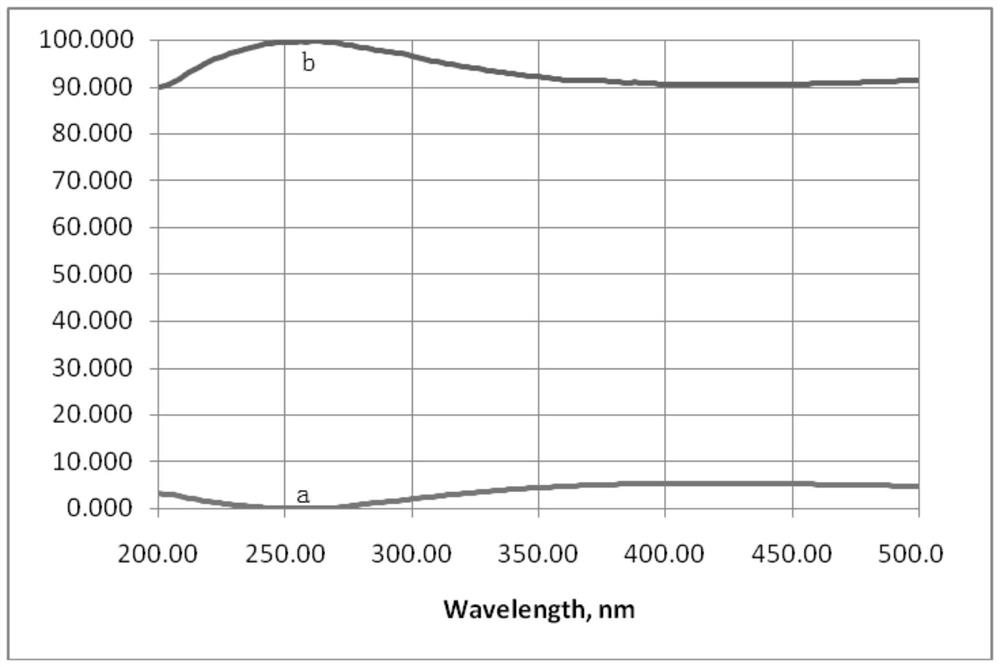

[0028] Such as figure 1 As shown, the 266nm high-power laser anti-reflection coating, the film layer structure is: A / cL / bH / aL / SUB / aL / bH / cL / A, where SUB stands for fused silica substrate; A stands for air; H stands for AL 2 o 3 film layer; L stands for MgF 2 film layer; a﹑b﹑c are the coefficients of the quarter reference wavelength optical thickness of each film layer, a is 1.6, b is 0.53, c is 1.13, and the physical thickness of each film layer is A / 52.36nm / 20nm / 75.44nm / SUB / 75.44nm / 20nm / 52.36nm / A.

[0029] The preparation of the above-mentioned 266 nanometer high-power laser anti-reflection coating comprises the following steps:

[0030] (1) Evaporation environment maintenance: add an isolation baffle between the evaporation source and the glass substrate to block and absorb ineffective evaporation materials, reduce pollution near the glass substrate, and reduce the probability of film defect formation;

[0031] (2) Ultrasonic cleaning: remove the microscopic particles at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com