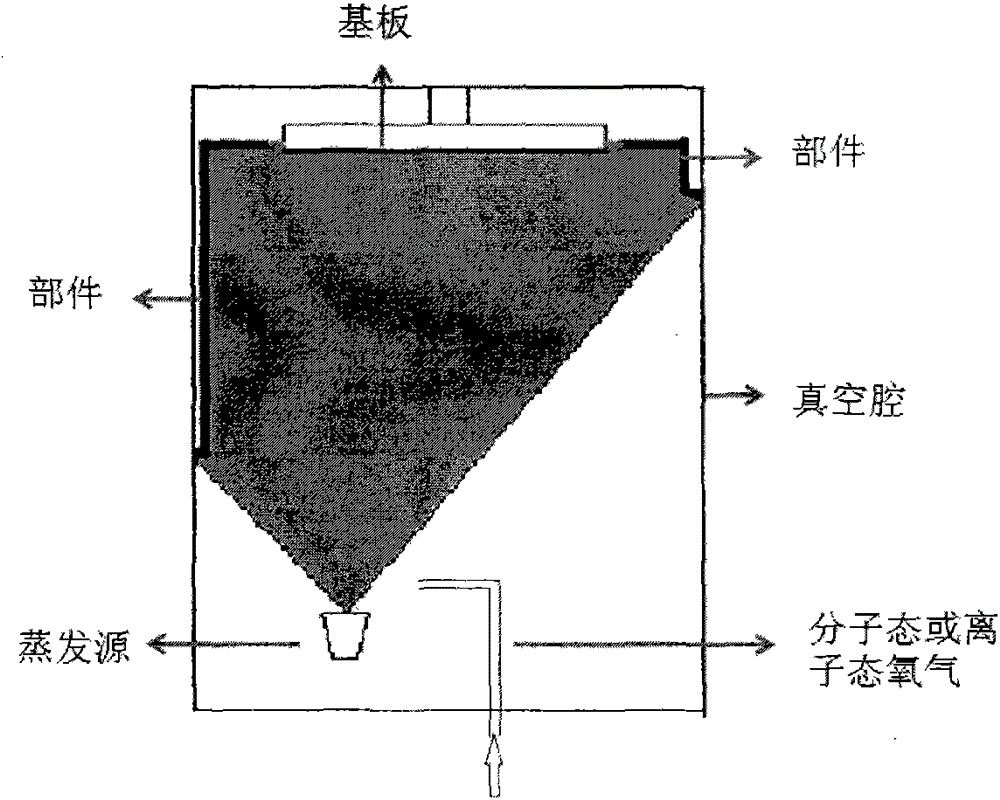

An Evaporation Method for Improving the Anti-laser Damage Threshold of Oxide Thin Films

An oxide film, damage threshold technology, applied in vacuum evaporation coating, optics, optical components, etc., can solve the problems of nodule formation, contamination of film, lower film threshold, etc., to reduce extinction coefficient, reduce intrinsic absorption, The effect of the simple structure of the baffle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

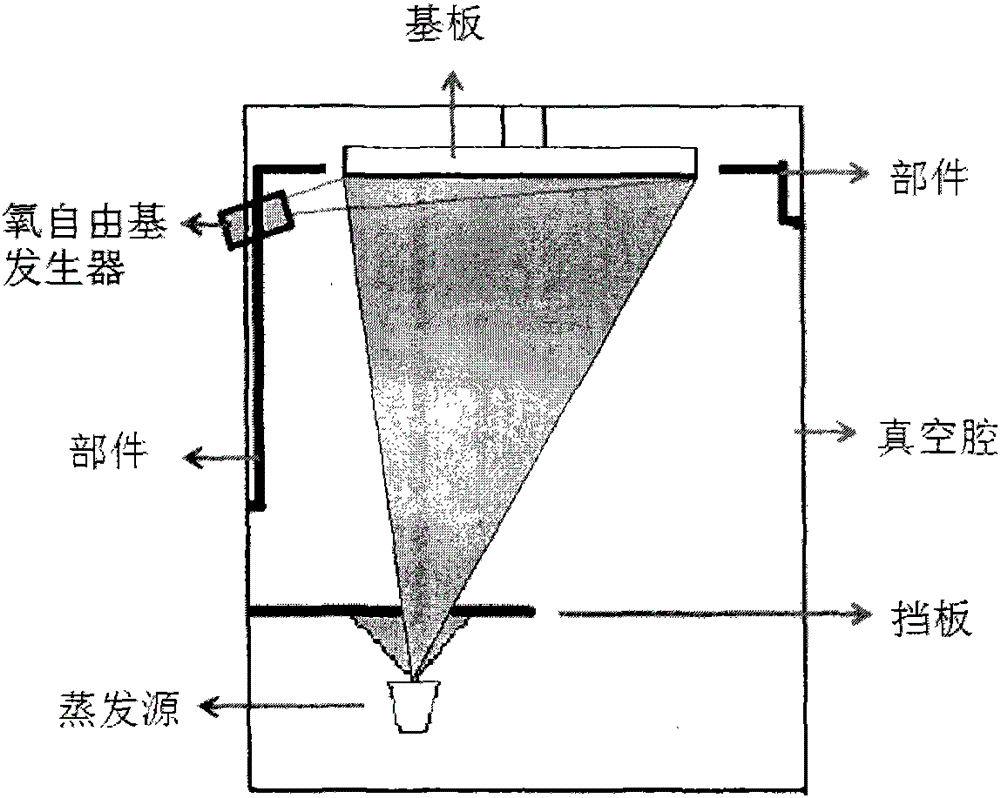

Embodiment 1

[0032] Using quartz glass as the substrate, first put it into the cleaning solution and ultrasonically clean it for 7 minutes, then wash it with deionized water, take it out and blow it dry with high-purity nitrogen, and then put it on the workpiece rack in the coating equipment; control the inside of the coating machine The background vacuum of the vacuum chamber is 1×10 -4 Pa; heat the substrate to 220 degrees and keep the temperature constant for 100 minutes, then use electron beam thermal evaporation to plate metal Hf, the evaporation rate is 0.015nm / s; introduce oxygen free radical gas at an angle of 80 degrees, and the flow rate is 4.5×10 15 Atomic number / (cm 2 s) After the coating is finished, take out the coated sample after the vacuum chamber is cooled to room temperature.

[0033] Compared with the film prepared by traditional evaporation, it was found that the extinction coefficient of the film evaporated by this method at 355nm was 2.6×10 -4 Reduced to 1×10 -5 A...

Embodiment 2

[0035] Using quartz glass as the substrate, first put it into the cleaning solution and ultrasonically clean it for 7 minutes, then wash it with deionized water, take it out and blow it dry with high-purity nitrogen, and then put it on the workpiece rack in the coating equipment; control the inside of the coating machine The background vacuum of the vacuum chamber is 1×10 -4 Pa; after heating the substrate to 200 degrees and keeping the temperature constant for 90 minutes, the hafnium dioxide was plated by electron beam thermal evaporation, the evaporation rate was 0.02nm / s; the oxygen free radical gas was introduced at an angle of 80 degrees, and the flow rate was 4.0×10 15 Atomic number / (cm 2 s); after the coating is completed, take out the coated sample after the vacuum chamber is cooled to room temperature.

[0036] Compared with the film prepared by traditional evaporation, it is found that the extinction coefficient of the film deposited by this method at 355nm is 2×10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com