Moisture-absorbing and heating knitted fabric with long-time controllable heating temperature and preparation method thereof

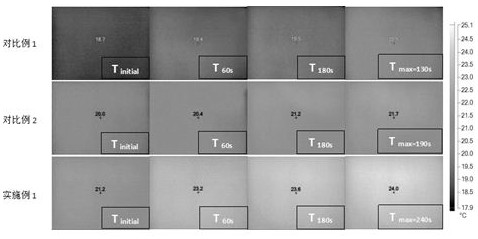

A technology of heating temperature, moisture absorption and heat generation, applied in knitting, weft knitting, fabric surface trimming, etc., can solve the problems of difficulty in delaying heat generation by moisture storage function, uneven heat, and rapid heat generation of moisture-absorbing and heating fabrics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

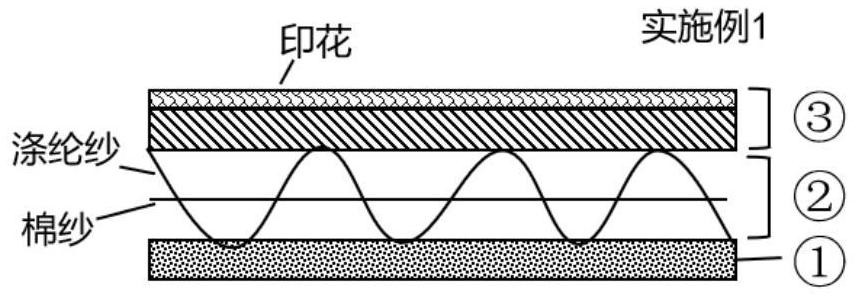

Embodiment 1

[0062] A method for preparing a moisture-absorbing and heating knitted fabric based on long-term controllable heating temperature, the specific steps are as follows:

[0063] (1) A double-sided large circular knitting machine is used to weave a three-layer moisture-absorbing uniform and slow-heating fabric with a moisture absorption gradient. The inner layer of the fabric is made of special-shaped cross-section polyester yarn and polyester / cotton blended yarn and is woven into a loop. The outer layer of the fabric is made of It is made of moisture-absorbing and heating fiber / viscose fiber blended yarn in loops. The middle layer of the fabric is made of ordinary polyester yarn. The inner and outer layers of the fabric are connected by loops, supplemented by cotton interlining weft.

[0064] (2) Pre-treatment, the technological process is: cylinder matching→oil washing→dehydration→opening→setting→rolling.

[0065] (3) The fabric is finished by padding method, and the technologic...

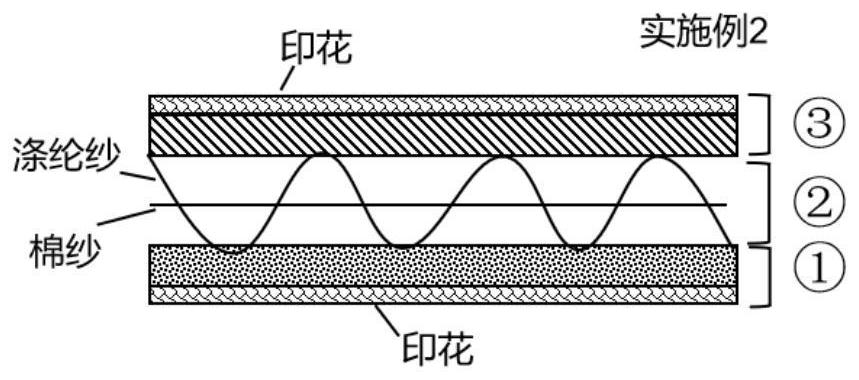

Embodiment 2

[0080] A method for preparing a moisture-absorbing and heating knitted fabric based on long-term controllable heating temperature, the specific steps are as follows:

[0081] (1) Moisture absorption and perspiration finishing of polyester cheese yarn by dipping method, the process flow is: preparation of finishing solution→dipping→pre-baking→baking→cleaning→drying. The preparation of the finishing solution is the same as step (3) in Example 1.

[0082] (2) Weaving into cloth, the fabric base structure is the moisture-absorbing uniform and slow heating fabric structure of the prior art, the concrete steps are basically the same as the step (1) in the example 1, the difference is that the connecting yarn of the middle layer of the fabric of the embodiment 2 adopts the embodiment Yarn after finishing in step (1) in 2.

[0083] (3) Use the flat screen printing method to carry out severe discontinuous hydrophilic finishing on the surface of the inner layer of the fabric. The process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com