Non-quenched and tempered steel plate and production method thereof

A technology of non-quenched and tempered steel and production method, which is applied in the field of steel plate rolling, can solve the problems of segregation of C and Mn elements, and achieve the effects of reducing grain boundary strengthening, fine and uniform structure, and delaying the precipitation of cementite in the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

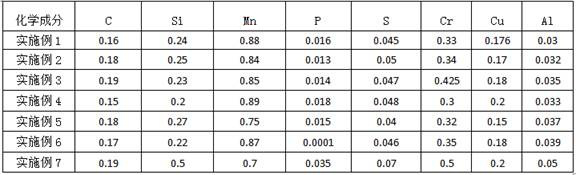

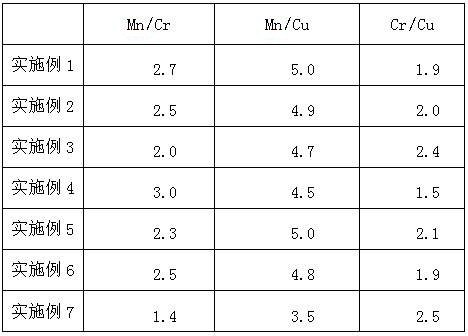

Embodiment 1

[0024] The chemical composition of the plate and its weight percentage are shown in Table 1. The production process includes continuous casting, slab heating, rough rolling, finishing, laminar cooling, stack cooling, and continuous casting. 400A, the slab is surface quenched at the end of continuous casting, the surface of the slab is cooled to 350°C, and the reddening temperature of the slab is 450°C. In the slab heating process, the slab temperature is heated to 1100°C, and the total heating time is calculated according to the thickness of 4.5min / cm. In the rough rolling process, the single-pass reduction rate is 15%, and the total reduction rate is 50%. In the finishing rolling process, the single-pass reduction rate is 10%, and the total reduction rate is 30%; the opening rolling temperature is 850 °C, and the final rolling temperature is 750 °C. In the laminar cooling process, the final cooling temperature is 550°C. In the stacking cooling process, after the straighteni...

Embodiment 2

[0026] The chemical composition of the plate and its weight percentage are shown in Table 1. The production process includes continuous casting, slab heating, rough rolling, finishing, laminar cooling, stack cooling, and continuous casting. At 350A, the slab is surface quenched at the end of continuous casting, the surface of the slab is cooled to 377°C, and the reddening temperature of the slab is 473°C. In the slab heating process, the slab temperature is heated to 1117°C, and the total heating time is calculated according to the thickness of 4.71 min / cm. In the rough rolling process, the single-pass reduction rate is 16.4%, and the total reduction rate is 53.7%. In the finishing rolling process, the single-pass reduction rate is 12%, and the total reduction rate is 33.3%; the opening rolling temperature is 864 °C, and the final rolling temperature is 767 °C. In the laminar cooling process, the final cooling temperature is 573°C. In the stack cooling process, after the str...

Embodiment 3

[0028] The chemical composition of the plate and its weight percentage are shown in Table 1. The production process includes continuous casting, slab heating, rough rolling, finishing, laminar cooling, stack cooling, and continuous casting. 420A, the slab is surface quenched at the end of continuous casting, the slab surface is cooled to 406°C, and the reddening temperature of the slab is 498°C. In the slab heating process, the slab temperature is heated to 1132°C, and the total heating time is calculated according to the thickness of 4.93 min / cm. In the rough rolling process, the single-pass reduction rate is 17.8%, and the total reduction rate is 57%. In the finishing rolling process, the single-pass reduction rate is 13%, and the total reduction rate is 36.5%; the opening rolling temperature is 877 °C, and the final rolling temperature is 781 °C. Laminar cooling process, the final cooling temperature is 599 ℃. In the stacking cooling process, after the straightening is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com