Treatment method of high-fluorine-chlorine secondary zinc oxide slag

A treatment method and high fluorine and chlorine times technology, applied in the direction of zinc sulfate, process efficiency improvement, instruments, etc., can solve the problems of difficult operation, complicated procedures, and too much soda ash.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

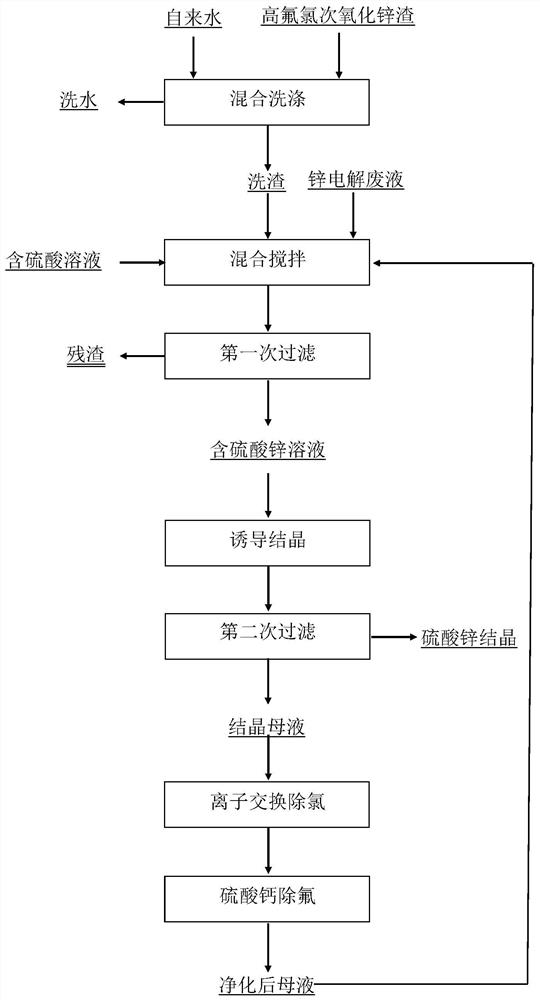

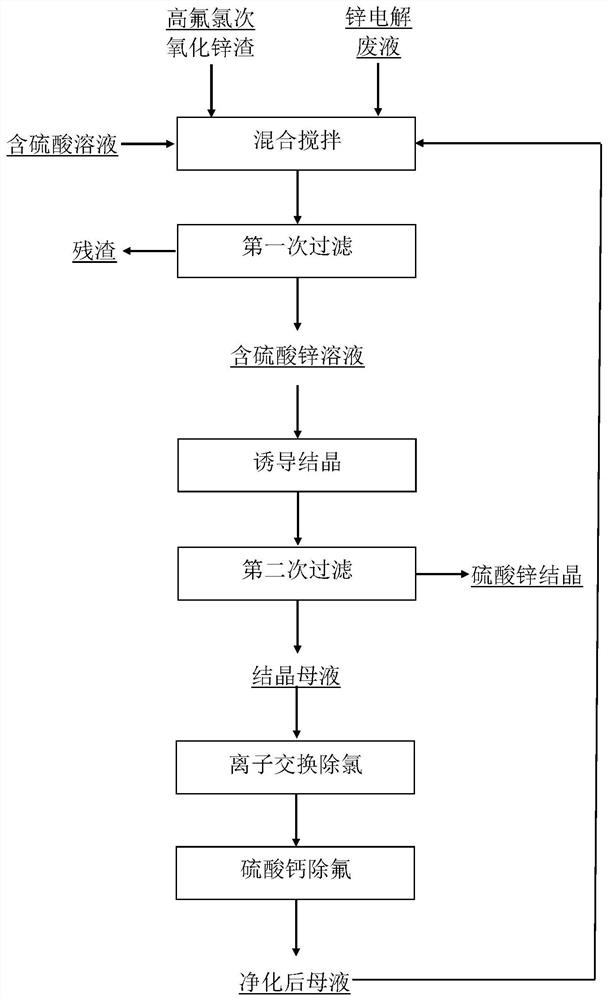

Method used

Image

Examples

Embodiment 1

[0051] The composition of high-fluorine chlorine suboxide zinc oxide waste residue is as follows:

[0052] The mass fraction of Zn is 58%, the mass fraction of O is 26%, the mass fraction of Pb is 0.017%, the mass fraction of F is 0.68%, the mass fraction of Cl is 0.36%, and the mass fraction of S is 7.5%.

[0053] The composition of zinc electrolytic waste liquid is as follows:

[0054] The zinc concentration is 160g / L, the sulfate radical concentration is 240g / L, the fluoride ion concentration is 20mg / L, and the chloride ion concentration is 20mg / L.

[0055] S1. Mix 40g of secondary zinc oxide waste residue and 80mL of tap water according to the solid-to-liquid ratio of 1:2, wash for 1 hour, and filter to obtain 57.1mL of washing residue and 62.9mL of washing water.

[0056] After testing, the fluoride ion concentration in the washing water was 550 mg / L, and the chloride ion concentration was 1215 mg / L.

[0057] S2. Mix 57.1mL of slag washing, 400mL of zinc electrolysis wa...

Embodiment 2

[0066] The composition of high-fluorine chlorine suboxide zinc oxide waste residue is as follows:

[0067] The mass fraction of Zn is 58%, the mass fraction of O is 26%, the mass fraction of Pb is 0.017%, the mass fraction of F is 0.68%, the mass fraction of Cl is 0.36%, and the mass fraction of S is 7.5%.

[0068] The composition of zinc electrolytic waste liquid is as follows:

[0069] The zinc concentration is 155g / L, the sulfate radical concentration is 230g / L, the fluoride ion concentration is 20mg / L, and the chloride ion concentration is 20mg / L.

[0070] S1. Mix 40g of secondary zinc oxide waste residue and 400mL of tap water according to the solid-to-liquid ratio of 1:10, wash for 1 hour, and filter to obtain 56mL of washing residue and 384mL of washing water.

[0071] After testing, the fluoride ion concentration of the washing water is 378 mg / L, and the chloride ion concentration is 552 mg / L.

[0072] S2. Mix 56mL of slag washing, 400mL of zinc electrolysis waste li...

Embodiment 3

[0081] The composition of high-fluorine chlorine suboxide zinc oxide waste residue is as follows:

[0082] The mass fraction of Zn is 58%, the mass fraction of O is 26%, the mass fraction of Pb is 0.017%, the mass fraction of F is 0.68%, the mass fraction of Cl is 0.36%, and the mass fraction of S is 7.5%.

[0083] The composition of zinc electrolytic waste liquid is as follows:

[0084] The zinc concentration is 160g / L, the sulfate radical concentration is 240g / L, the fluoride ion concentration is 20mg / L, and the chloride ion concentration is 20mg / L.

[0085] S1. Mix 20g of secondary zinc oxide waste residue and 40mL of tap water according to the solid-to-liquid ratio of 1:2, wash for 1 hour, and filter to obtain 28.6mL of washing residue and 31.4mL of washing water.

[0086] After testing, the fluoride ion concentration of the mixed washing water was 552 mg / L, and the chloride ion concentration was 1203 mg / L.

[0087] S2. Mix 28.6mL washing residue, 400mL zinc electrolysis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com