System and method for joint production of electronic chlorine and electronic hydrogen chloride

A technology of hydrogen chloride and chlorine gas, which is applied in the direction of chlorine/hydrogen chloride, chlorine/hydrogen chloride purification, hydrogen chloride preparation, etc., which can solve the problems of high raw material cost and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

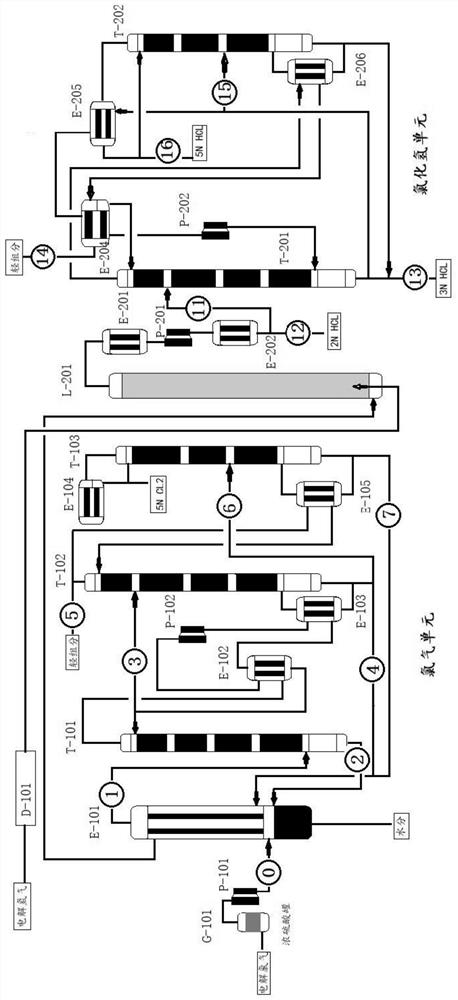

[0095] Such as figure 1 As shown, the electrolytic chlorine gas is initially dewatered through the concentrated sulfuric acid tank, then pressurized by the compressor P-101, and enters the tube of the falling film condenser E-101 to condense and dewater. The dehydrated chlorine gas discharged from the top of the falling film condenser E-101 enters the lower part of the low-temperature heat pump dehydration tower T-101 to remove residual water in the chlorine gas. The water-containing chlorine stream produced from the lower part of the tower also enters the tube of the falling film condenser E-101; while the low-temperature dehydrated chlorine stream produced from the top of the low-temperature heat pump dehydration tower T-101 passes through the tube-and-tube heat exchanger E- After 102 heat exchange, the compressor P-102 compresses and heats up, and the high-temperature chlorine stream is used as the heat source of the double-effect light removal tower T-102 tower kettle, so ...

Embodiment 2

[0104] refer to figure 2 , the chlorine production unit of this embodiment system is the same as the above-mentioned figure 1 The chlorine gas production unit is the same and will not be repeated here.

[0105] Introduced below figure 2 Hydrogen Chloride Production Units:

[0106] The synthetic hydrogen chloride gas discharged from the synthesis furnace L-201 is pressurized to a higher pressure by the compressor P-201, and then condensed and liquefied by a water cooler, most of which can be used as 2N industrial grade hydrogen chloride products; and the other part The liquid enters the upper part of the double-effect light removal tower T-201 to remove light components.

[0107] Double-effect light removal tower T-201 is a high-pressure double-effect rectification tower with high pressure and high saturation temperature, and gaseous hydrogen chloride containing light components is extracted from the top of the tower. This hydrogen chloride gas can be used as the heat sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com