Method for reducing heavy metal cadmium in ganoderma lucidum spore powder

A technology of Ganoderma lucidum spore powder and heavy metals, which is applied in chemical instruments and methods, functions of food ingredients, and other chemical processes, and can solve problems such as difficult excretion and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

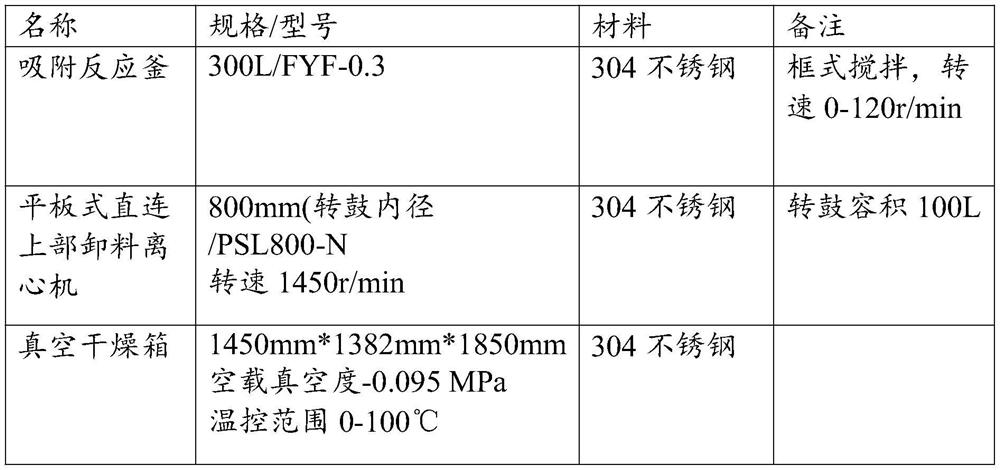

[0021] The method for reducing the heavy metal cadmium in Ganoderma lucidum spore powder comprises the following steps:

[0022] 1. Adsorption

[0023] Pour 200L of 14% phytic acid solution into a 300L soaking reactor, put in 20Kg of Ganoderma lucidum spore powder raw material at a speed of 40r / min, raise the temperature to 45°C, keep it warm for 2 hours, drop the material to 28°C, and start dehydration and separation.

[0024] 2. Separation

[0025] The centrifuge uses a 300-mesh filter bag to separate the solid from the liquid and reuse the filtrate. The solid Ganoderma lucidum spore powder is washed and then dried, and placed in a stainless steel material tray to enter the drying process.

[0026] 3. Drying

[0027] Use a vacuum drying oven with a vacuum degree of -0.08MPa and a drying temperature of 60°C to dry the Ganoderma lucidum spore powder, and collect the material when the moisture content of the material is ≤8%.

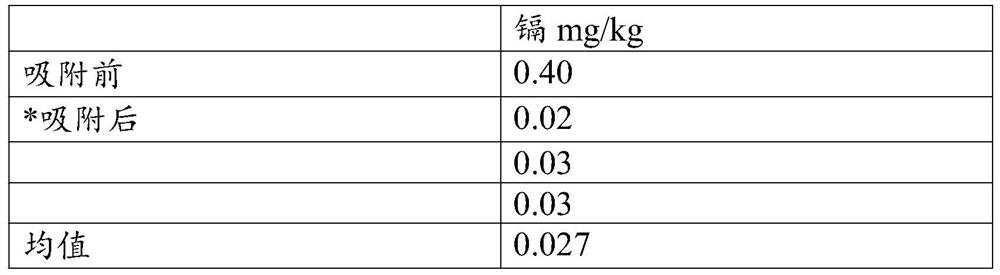

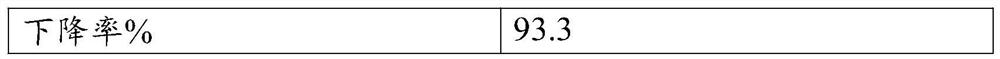

[0028] Table 1 is the comparison before and afte...

Embodiment 2

[0034] The method for reducing the heavy metal cadmium in Ganoderma lucidum spore powder comprises the following steps:

[0035] 1. Adsorption

[0036] Pour 140L of 12% phytic acid solution into a 300L soaking reactor, put in 20Kg of Ganoderma lucidum spore powder raw material at 60r / min, raise the temperature to 45°C, keep it warm for 2 hours, drop the material to 30°C, and start dehydration and separation.

[0037] 2. Separation

[0038] The centrifuge uses a 300-mesh filter bag to separate the solid from the liquid and reuse the filtrate. The solid Ganoderma lucidum spore powder is washed and then dried, and placed in a stainless steel material tray to enter the drying process.

[0039] 3. Drying

[0040] Use a vacuum drying oven with a vacuum degree of -0.08MPa and a drying temperature of 60°C to dry the Ganoderma lucidum spore powder, and collect the material when the moisture content of the material is ≤8%.

[0041] Table 2 is the comparison before and after adsorptio...

Embodiment 3

[0045] The method for reducing the heavy metal cadmium in Ganoderma lucidum spore powder comprises the following steps:

[0046] 1. Adsorption

[0047] Pour 160L of 13% phytic acid solution into a 300L soaking reactor, put in 20Kg of Ganoderma lucidum spore powder raw material at a speed of 60r / min, raise the temperature to 45°C, keep it warm for 2 hours, drop the material to 30°C, and start dehydration and separation.

[0048] 2. Separation

[0049] The centrifuge uses a 300-mesh filter bag to separate the solid from the liquid and reuse the filtrate. The solid Ganoderma lucidum spore powder is washed and then dried, and placed in a stainless steel material tray to enter the drying process.

[0050] 3. Drying

[0051] Use a vacuum drying oven with a vacuum degree of -0.08MPa and a drying temperature of 60°C to dry the Ganoderma lucidum spore powder, and collect the material when the moisture content of the material is ≤8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com