Quantum dot color conversion layer and preparation method thereof

A technology of color conversion layer and quantum dots, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of lower conversion efficiency, difficulty in realization, and degradation of quantum dots, and achieve high material utilization, high preparation accuracy, and suppression stray light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

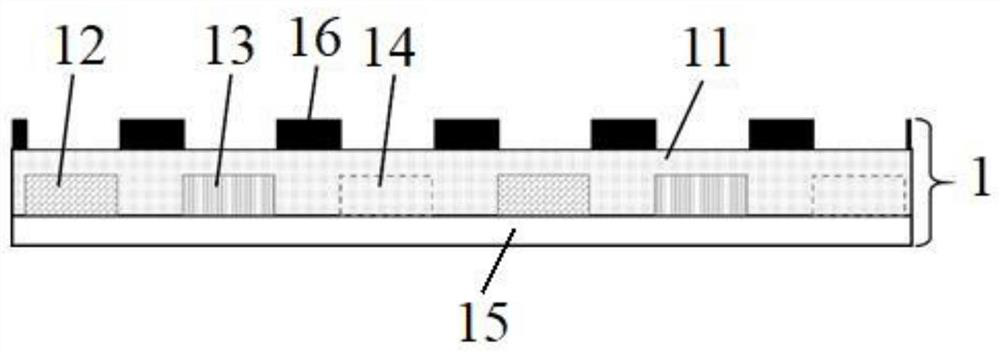

[0045] figure 1 Shown is the structure of the quantum dot color conversion layer according to Embodiment 1 of the present invention.

[0046] like figure 1 As shown, the quantum dot color conversion layer 1 provided by Embodiment 1 of the present invention includes: a microfluidic substrate 11 and a transparent substrate 15, the transparent substrate 15 is pressed on the bottom side of the microfluidic substrate 11, and the microfluidic substrate 11 Red light quantum dots 12, green light quantum dots 13 and transmission areas 14 are formed inside, the red light quantum dots 12 are used to convert blue light into red light, the green light quantum dots 13 are used to convert blue light into green light, and the transmission area 14 is used to make blue light Shot directly without changing the color.

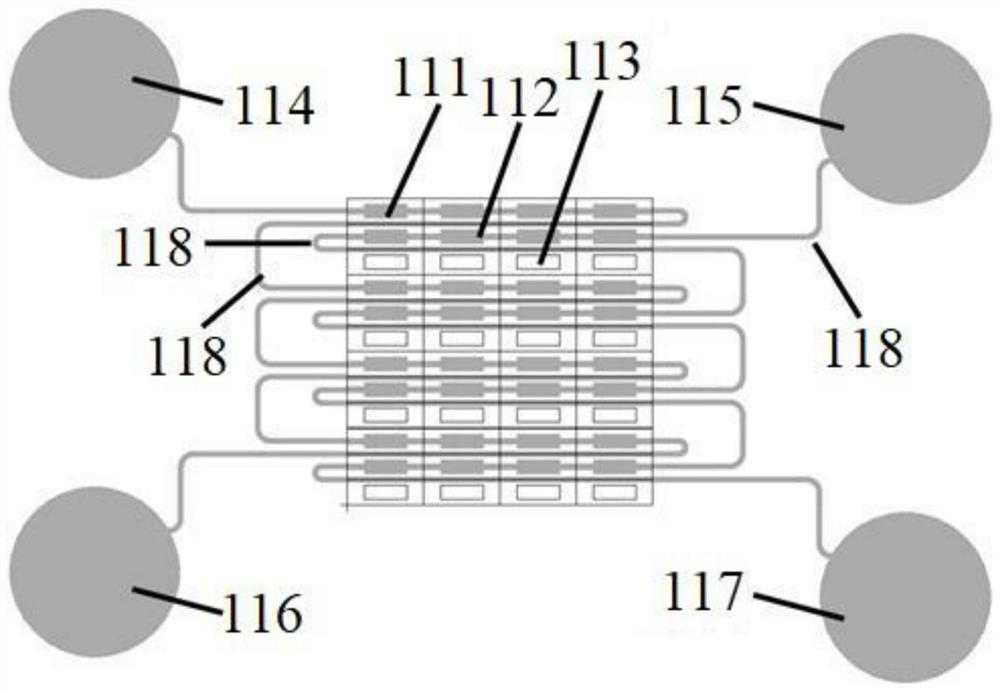

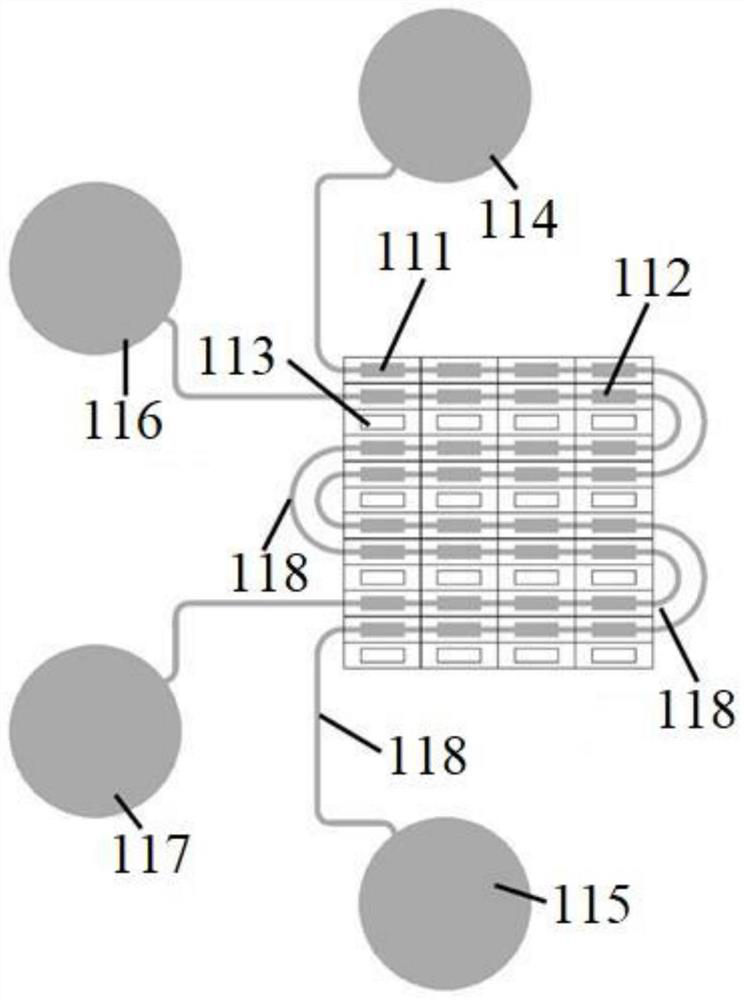

[0047] figure 2 A structure of a microfluidic channel substrate according to Embodiment 1 of the present invention is shown.

[0048] like figure 2As shown, the microfluidi...

Embodiment 2

[0071] Figure 5 The structure of the quantum dot color conversion layer according to the second embodiment of the present invention is shown.

[0072] like Figure 5 As shown, the quantum dot color conversion layer 1 of Embodiment 2 of the present invention includes a microfluidic substrate 11 and a transparent substrate 15. The difference from Embodiment 1 is that the transparent substrate 15 is pressed on the top side of the microfluidic substrate 11, and the isolation barrier 16 is prepared on the transparent substrate 15. The specific structure of the micro-channel substrate 11 is the same as that of the micro-channel substrate 11 in the first embodiment, so it will not be repeated here.

[0073] Image 6 It is the integration of the quantum dot color conversion layer and the background light Micro-LED array according to the second embodiment of the present invention

[0074] like Image 6 As shown, after the fabrication of the quantum dot color conversion layer 1 is...

Embodiment 3

[0077] Figure 7 and Figure 8 The flow and dynamic process of the preparation method of the quantum dot color conversion layer according to the third embodiment of the present invention are respectively shown.

[0078] like Figure 7 and Figure 8 As shown, the preparation method of the quantum dot color conversion layer provided by the third embodiment of the present invention includes the following steps:

[0079] S1. Design and fabricate a patterned mask substrate according to the distribution of pixels.

[0080] The pixel point includes at least one group of quantum dot positions for injecting quantum dot solution to realize the color conversion of original light, and a micro flow channel for realizing flow of quantum dot solution.

[0081] The quantum dots are divided into two types according to the color, namely the red quantum dots 111 and the green quantum dots 112, the red quantum dots 111 are used to inject the red quantum dot solution, and the green quantum dots ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com