Nickel electrode slurry, preparation method and application thereof

A nickel electrode and slurry technology, applied in the direction of fixed capacitor electrodes, circuits, capacitors, etc., can solve the problems of large spacing, reducing the oxidation resistance of nickel particles, and low pulping efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

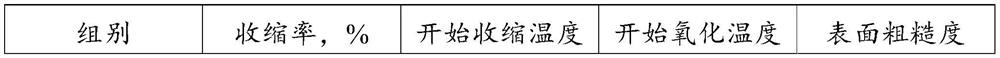

Examples

Embodiment 1

[0059] A nickel electrode slurry, which consists of the following components in mass fraction: coated nickel powder 54%, barium titanate particles 3%, binder 6.5%, dispersant 2.5%, solvent 24% and thinner 10% %; In coated nickel powder, the mass fraction of nickel powder in the nickel electrode slurry is 50%, and the mass fraction of the barium titanate coating layer in the nickel electrode slurry is 4%. The dispersant is SC-0505K dispersant; the solvent is dihydroterpineol; the diluent is MSA; the adhesive is composed of EC resin and PVB resin, and the mass ratio of EC resin to PVB resin is 2:1; coating type In the nickel powder, the particle size of the nickel powder is 300nm, the thickness of the barium titanate coating layer is 10nm; the particle size of the barium titanate particles is 50nm.

[0060] The preparation method of the nickel electrode slurry of embodiment 1 comprises following preparation steps:

[0061] (1) Preparation of nickel master slurry: mix coated nic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com