Highly-integrated crankcase ventilation and separation device

A crankcase ventilation and separation device technology, which is applied in crankcase ventilation, engine components, machines/engines, etc., can solve the problems of engine lubrication system threat, difficulty in cleaning, and long blow-by gas circulation path, etc., to reduce the risk of oil emulsification, The effect of simplifying the layout of parts and simplifying the design complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

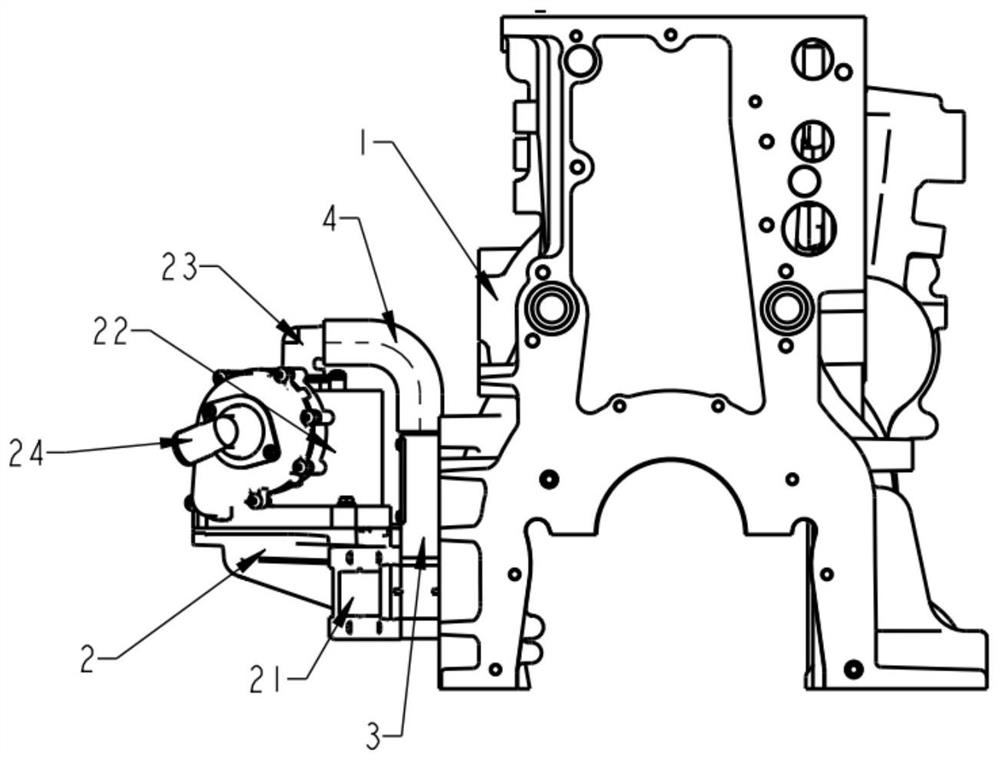

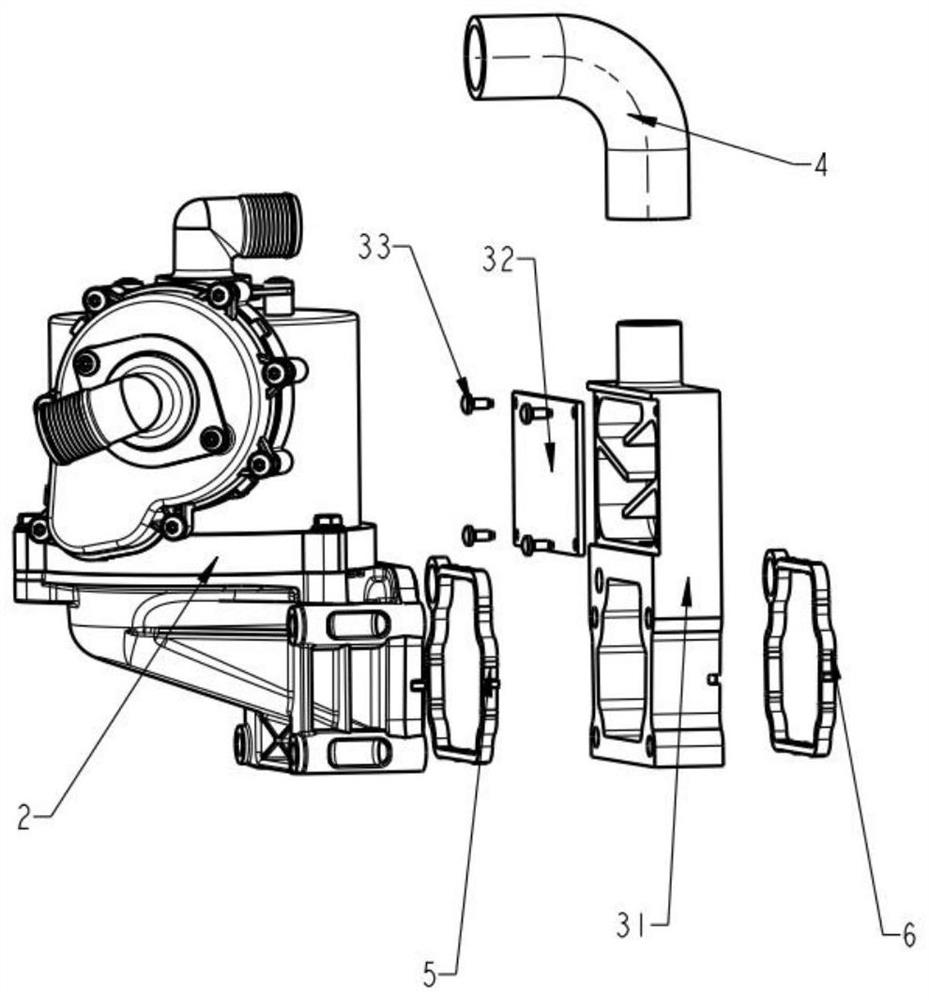

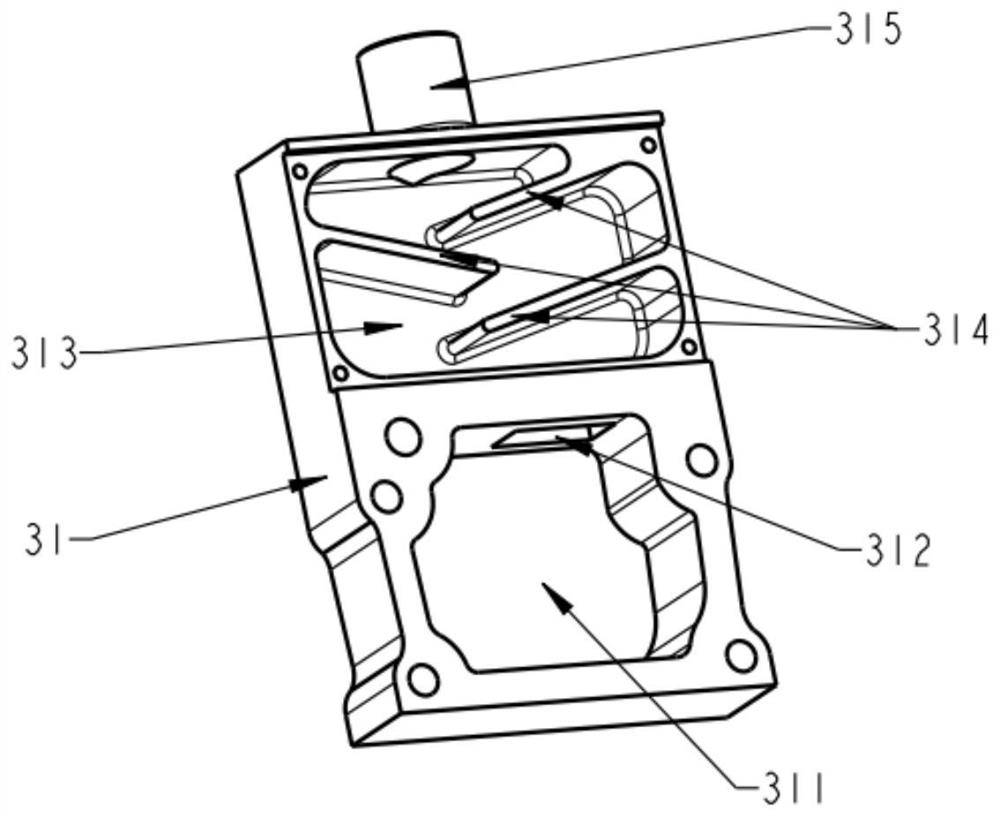

[0030] Such as Figure 1-3 As shown, the present invention includes a fine separation device 2 and a rough separation device 3, and the fine separation device 2 communicates with the rough separation device 3 through a pipeline 4; the rough separation device 3 includes a rough separation device body 31, and the rough separation device 3 The device body 31 includes an upper chamber and a lower chamber, the lower chamber is provided with a cylinder air intake port 311, and the upper chamber is provided with a separation labyrinth cavity 313, and the upper chamber and the lower chamber are communicated through the coarse separation device air intake port 312, so The air outlet 315 of the coarse separation device is opened on the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com