High-silicon high-temperature strengthened domestic porcelain and preparation method thereof

A high-temperature strengthening and high-silicon technology, applied in the field of ceramics, can solve the problems of affecting the quality of ceramics, impossibility of long-term use, low hardness of ceramics, etc., and achieve the effect of improving multi-practicability, increasing strength and low moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

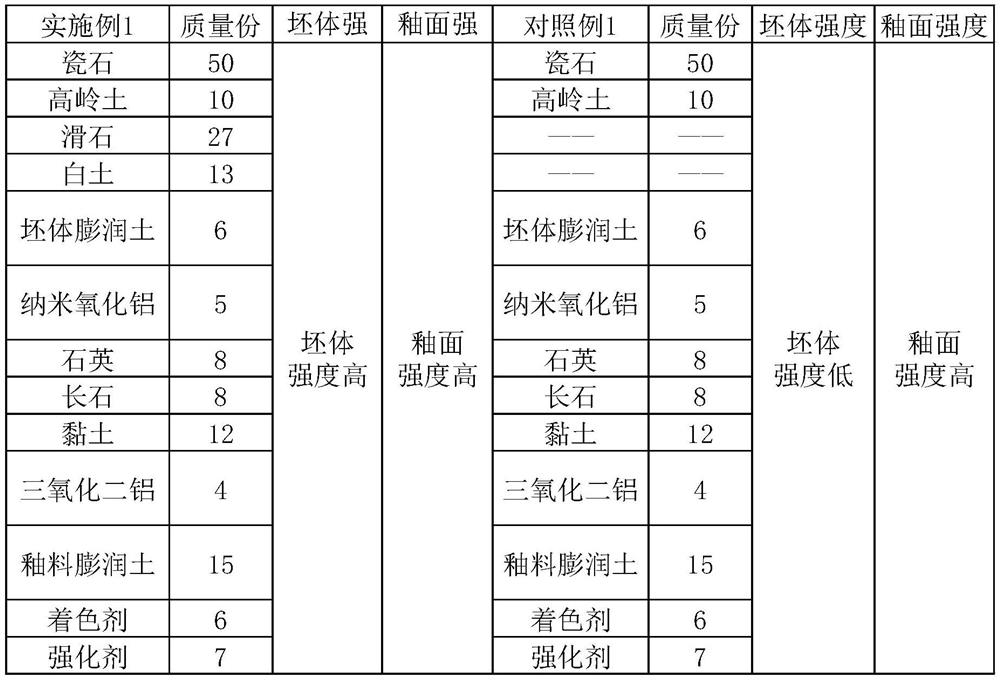

Embodiment 1

[0029] A high-silicon high-temperature strengthened daily-use porcelain and a preparation method thereof. The body raw materials are specifically: 50 parts by mass of porcelain stone, 10 parts by mass of kaolin, 27 parts by mass of talc, 13 parts by mass of white clay, 6 parts by mass of green body bentonite, nano 5 parts by mass of alumina; the glaze raw materials are specifically: 8 parts by mass of quartz, 8 parts by mass of feldspar, 12 parts by mass of clay, 4 parts by mass of aluminum oxide, 15 parts by mass of glaze bentonite, 6 parts by mass of colorant, strengthening 7 mass parts of agent.

[0030] The preparation method in the present embodiment comprises the following steps:

[0031] Step 1: Take porcelain stones from the mining area, and then put a certain proportion of porcelain stones into the coarse aggregate crusher to crush the porcelain stones, and then put the crushed porcelain stones into the fine aggregate crusher to crush the porcelain stones to powder, ...

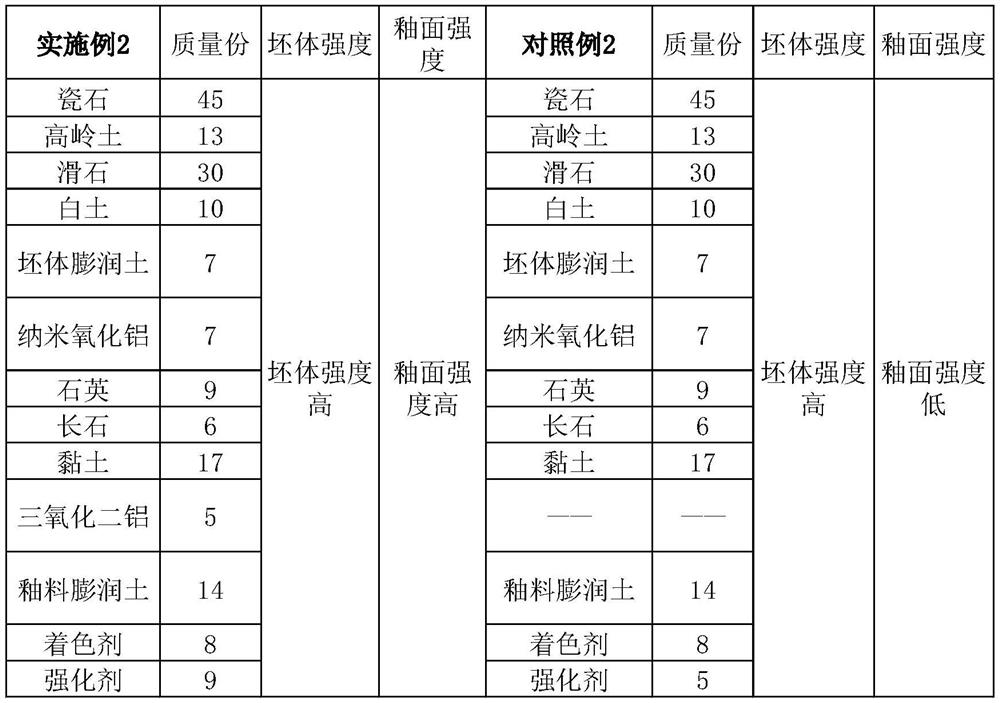

Embodiment 2

[0040] A high-silicon high-temperature strengthened daily-use porcelain and its preparation method. The raw materials of the green body are specifically: 45 parts by mass of porcelain stone, 13 parts by mass of kaolin, 30 parts by mass of talc, 10 parts by mass of white clay, 7 parts by mass of green body bentonite, nano 7 parts by mass of alumina; the glaze raw materials are specifically: 9 parts by mass of quartz, 6 parts by mass of feldspar, 17 parts by mass of clay, 5 parts by mass of aluminum oxide, 14 parts by mass of glaze bentonite, 8 parts by mass of colorant, strengthening 9 parts by mass.

[0041] The preparation method in the present embodiment comprises the following steps:

[0042] Step 1: Take porcelain stones from the mining area, and then put a certain proportion of porcelain stones into the coarse aggregate crusher to crush the porcelain stones, and then put the crushed porcelain stones into the fine aggregate crusher to crush the porcelain stones to powder,...

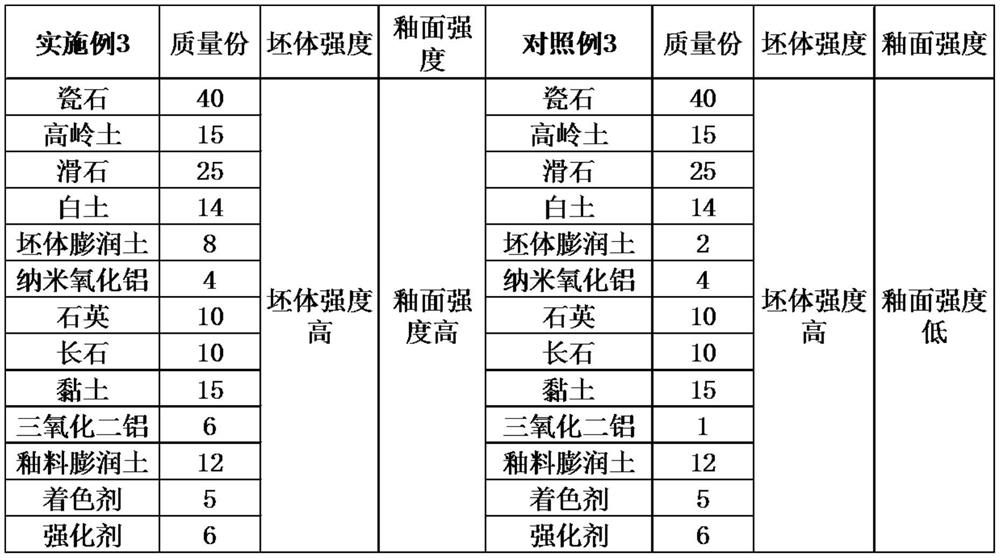

Embodiment 3

[0051] A high-silicon high-temperature strengthened daily-use porcelain and its preparation method. The raw materials of the green body are specifically: 40 parts by mass of porcelain stone, 15 parts by mass of kaolin, 25 parts by mass of talc, 14 parts by mass of white clay, 8 parts by mass of green body bentonite, nano 4 parts by mass of alumina; the glaze raw materials are specifically: 10 parts by mass of quartz, 9 parts by mass of feldspar, 15 parts by mass of clay, 6 parts by mass of aluminum oxide, 12 parts by mass of glaze bentonite, 5 parts by mass of colorant, strengthening 6 mass parts of agent.

[0052] The preparation method in the present embodiment comprises the following steps:

[0053] Step 1: Take porcelain stones from the mining area, and then put a certain proportion of porcelain stones into the coarse aggregate crusher to crush the porcelain stones, and then put the crushed porcelain stones into the fine aggregate crusher to crush the porcelain stones to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com