Device and method for detecting compatibility and gas generation features of solid material and liquid material

A compatibility and characteristic technology, applied in the direction of measuring devices, color measuring devices, material inspection products, etc., can solve the problems of insulating oil volume increase, processing difficulties, repetitive work, etc., to ensure test accuracy, improve accuracy, The effect of improving airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

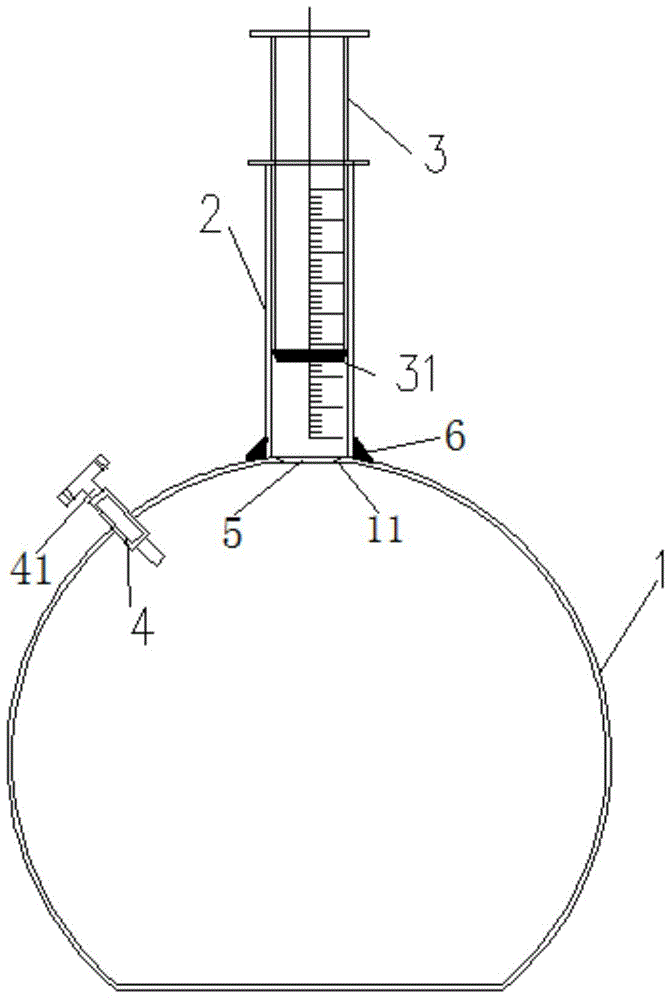

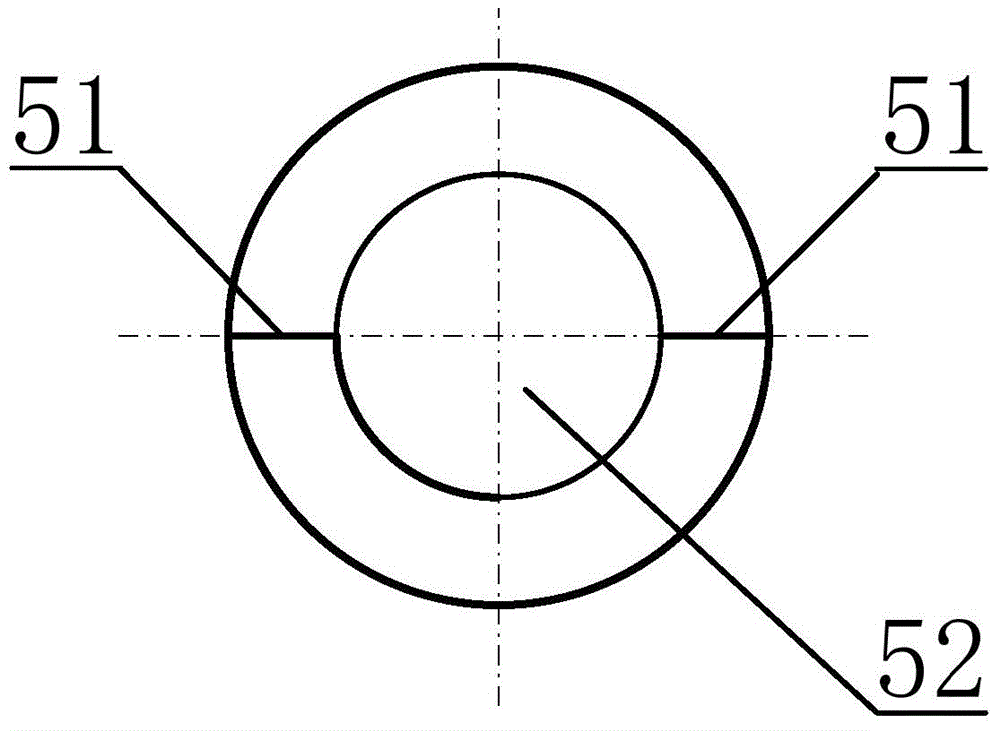

[0048] The device for testing solid-liquid material compatibility and gas production characteristics provided by the embodiments of the present invention, such as Figures 1 to 7 As shown, it includes: container 1, measuring tube 2, push rod 3, vent hole 4, packing plate 5, measuring hole 11, rubber plug 31, three-way switch 41, air gap 51, inlet hole 52, sealing rubber ring 6. The container 1 is a sphere with a flat bottom and is respectively provided with a measuring hole 11 and an exhaust hole 4, and a three-way switch 41 is installed in the exhaust hole 4; After the measuring tube 2 and the container 1 are bonded, the sealing rubber ring 6 is installed, and the measuring tube 2 is provided with a push rod 3, and a rubber plug 31 is installed on the top of the pushing rod 3 to isolate the air exchange inside and outs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com