Underground goaf filling material and preparation method and application thereof

A filling material and goaf technology, which is applied in the field of underground goaf filling materials and their preparation, can solve the problems of filling underground goafs, outstanding safety hazards, and no filling materials, etc., so as to ensure safe mining and eliminate safety hidden dangers and the effect of reducing cement consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention provides the preparation method of underground goaf filling material described in the above technical solution, comprising the following steps:

[0030] The fly ash, desulfurized gypsum, ordinary portland cement and water are fully stirred to obtain the underground gob filling material.

[0031] In the present invention, the fly ash, desulfurized gypsum and ordinary Portland cement are preferably first stirred and mixed to obtain a mixed dry material; then the mixed dry material is mixed with water for a second time to obtain an underground goaf filling material. In the present invention, the time for the first stirring and mixing and the second stirring and mixing is preferably independently 2-5 minutes. The present invention adopts the above-mentioned mixing method, which is beneficial to ensure uniform mixing and dispersion of each component. In the present invention, there is no special limitation on the stirring rate during the mixing process...

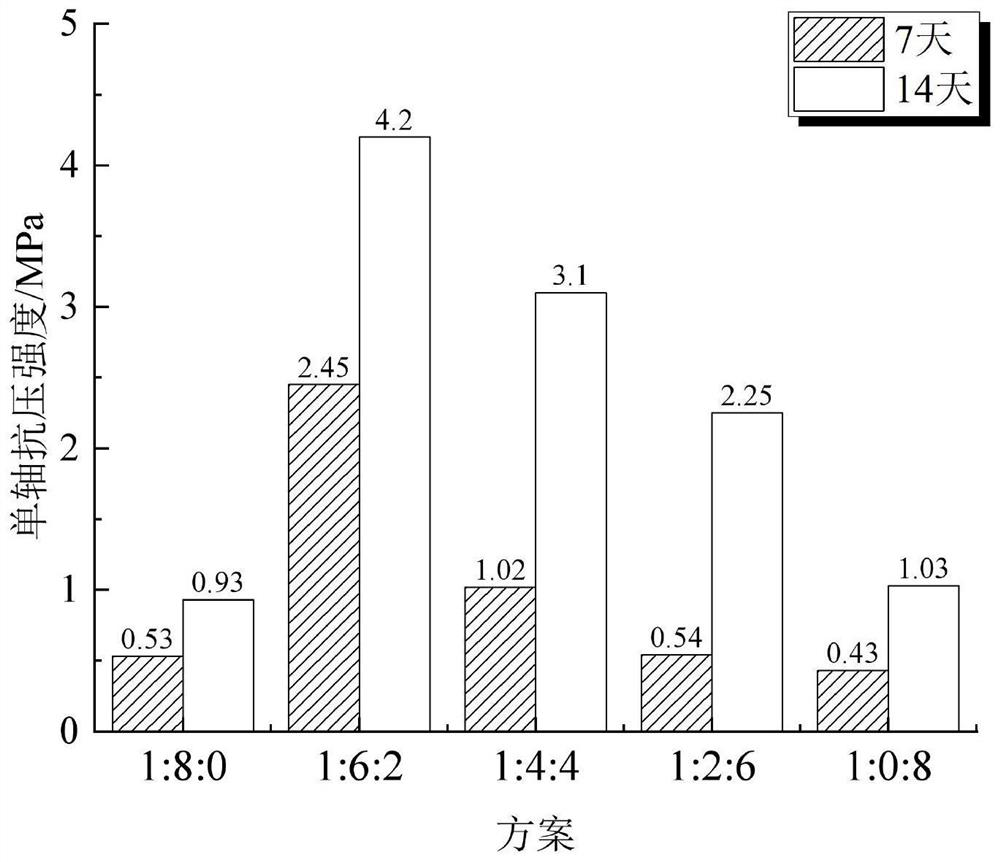

Embodiment 1~3

[0037] Stir and dry fly ash, desulfurized gypsum and ordinary Portland cement P.O.42.5R for 3 minutes to obtain a mixed dry material; stir and mix the mixed dry material with water to obtain an underground goaf filling material; wherein, the powder The main chemical components of coal ash, desulfurized gypsum and ordinary Portland cement P.O.42.5R are shown in Table 1, and the particle size distribution and specific surface area of the fly ash and desulfurized gypsum are shown in Table 2. The dosage of each component in the zone filling material is shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com