Preparation method of sodium percarbonate

A technology of sodium percarbonate and sodium carbonate decahydrate is applied in the field of chemical engineering and achieves the effects of good economic benefit, environmental protection and simple implementation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

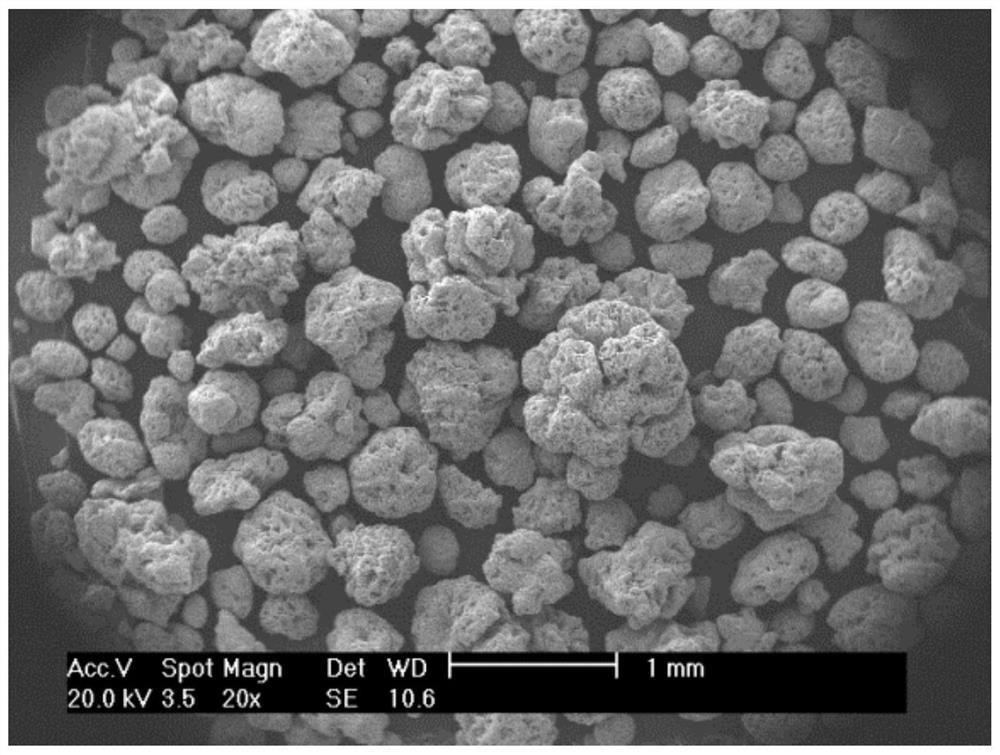

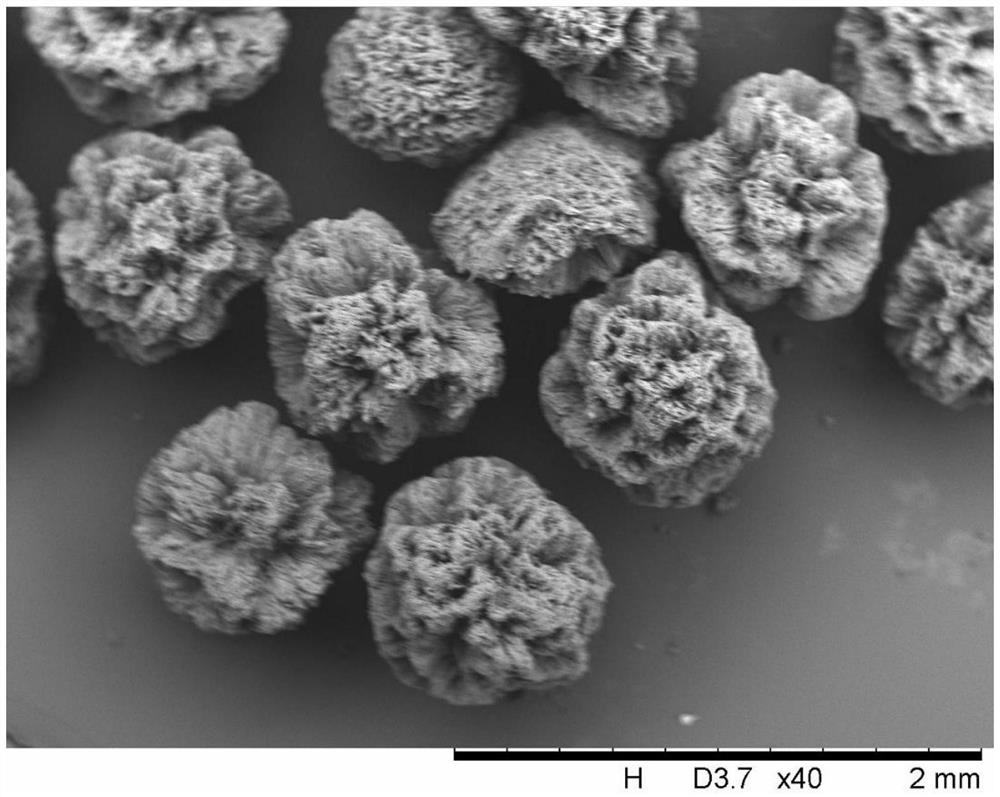

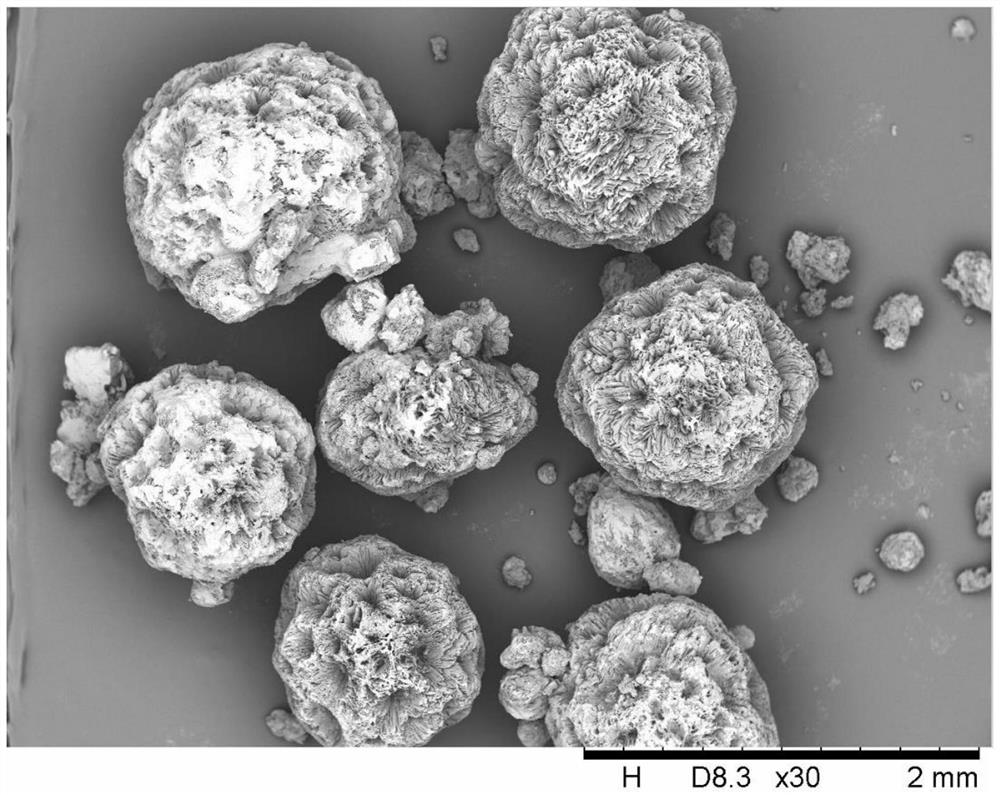

Image

Examples

Embodiment 1

[0048] Add sodium carbonate decahydrate and circulating mother liquor to the slurry tank at a mass ratio of 2:1, heat up to 30-40°C to dissolve, then add sodium chloride, so that the mass content of sodium chloride in the slurry is 15%, and the obtained The first reaction solution: Add 5 g of ethylenediaminetetraacetic acid (EDTA) and 5 g of aminotrimethylene phosphonic acid (ATMP) into a hydrogen peroxide solution with a mass concentration of 50% per kilogram, stir and dissolve to make a hydrogen peroxide mixed solution, which is the second The reaction solution was cooled to 0-10°C for later use; 100 g of sodium pyrophosphate was added to every kilogram of water, stirred and dissolved to obtain the third reaction solution.

[0049] Add circulating mother liquid into the reaction kettle as the bottom liquid, control the reaction temperature at 18-30°C, and prepare the prepared sodium carbonate decahydrate slurry (first reaction liquid) at 3.41m 3 / h, hydrogen peroxide mixed s...

Embodiment 2

[0051] Add sodium carbonate decahydrate and circulating mother liquor to slurry tank 1 at a mass ratio of 2:1, heat up to 30-40°C to dissolve, then add sodium chloride, so that the mass content of sodium chloride in the slurry is 15-18% , to obtain a first-level first reaction solution; sodium carbonate decahydrate and circulating mother liquor are added to the slurry tank 2 with a mass ratio of 2:1, heated to 30-40 ° C for dissolution, and then sodium chloride is added to make the chlorination in the slurry The mass content of sodium is 26-30%, and the secondary first reaction solution is prepared; 0.5 g of sodium polyacrylate and 0.8 g of hydroxyethylene diphosphoric acid are added to the hydrogen peroxide solution with a mass concentration of 27.5% per kilogram, and stirred and dissolved to prepare The hydrogen peroxide mixed solution is used as the second reaction solution, cooled to 0-10°C for later use; 150 g of sodium tripolyphosphate is added to each kilogram of water, ...

Embodiment 3

[0054] Add sodium carbonate decahydrate and circulating mother liquor to No. 1 slurry tank at a mass ratio of 2:1, heat up to 30-40°C to dissolve, then add sodium chloride, so that the mass content of sodium chloride in the slurry is 15-18 %, to obtain a first-level first reaction solution; aqueous sodium carbonate and circulating mother liquor are added to the No. 2 slurry tank with a mass ratio of 2:1, the temperature is raised to 30-40 ° C for dissolving, and then sodium chloride is added to make the slurry in the slurry The mass content of sodium chloride is 18-26%, and the secondary first reaction solution is obtained; Sodium carbonate decahydrate and circulating mother liquor are added to No. 3 slurry tank with a mass ratio of 2:1, and the temperature is raised to 30-40°C for dissolution , add sodium chloride again, make the mass content of the sodium chloride in the slurry be 26-30%, make three-stage first reaction liquid; Add magnesium sulfate 0.2g, 0.5g of EDTA and 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com