Bulletproof glass safety film

A bulletproof glass and safety film technology, applied in protective clothing, protective equipment, clothing, etc., can solve the problems that ordinary glass cannot achieve practical protection, the bulletproof glass diaphragm is not ideally resistant to strong impact, and is not easy to tear , The effect of strong bulletproof ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

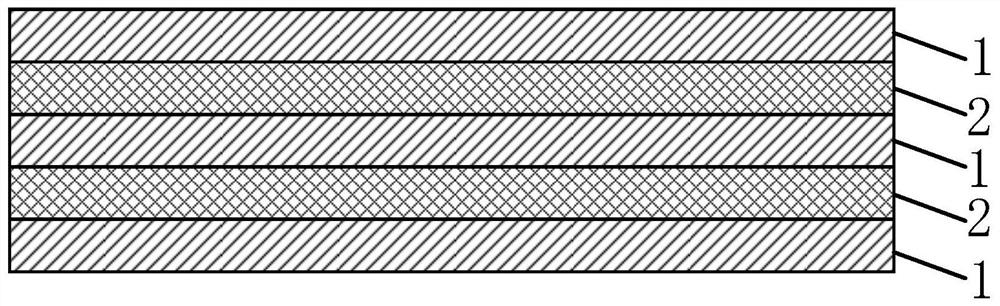

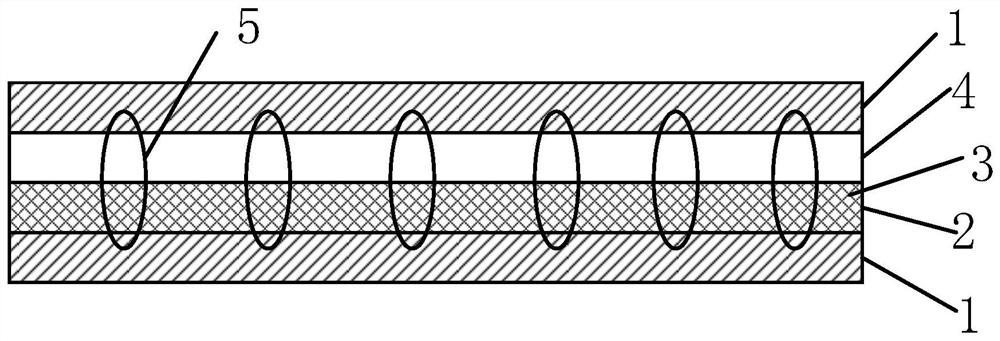

[0013] Such as figure 1 As shown, a bullet-proof glass safety film provided by an embodiment of the present invention includes: at least two layers of ultra-high molecular weight polyethylene calendered films, and bonding of pressure-sensitive adhesives between the ultra-high molecular weight polyethylene calendered films Layer, ultra-high molecular weight polyethylene calendered film is a composite film prepared by combining ultra-high molecular weight polyethylene and epoxy resin.

[0014] Among them, the bullet-proof glass safety film is a safety film with a total thickness of 0.28mm and 90% light transmission and anti-ultraviolet and anti-electromagnetic. To achieve functions such as anti-ultraviolet and anti-electromagnetic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com