Bulletproof helmet

A bulletproof helmet and helmet technology, applied in the field of bulletproof clothing, can solve the problems of high cost, heavy metal material, heavy wearing, etc., and achieve the effects of low cost, small specific gravity, and light wearing on the head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

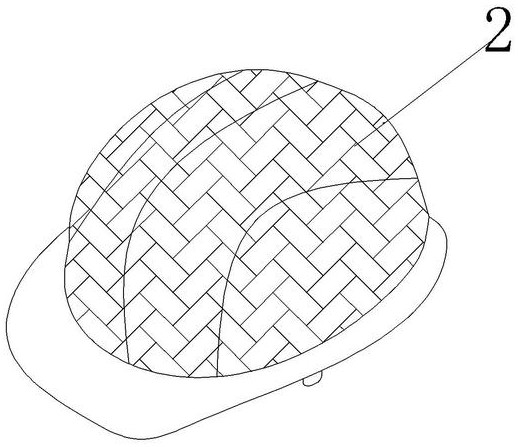

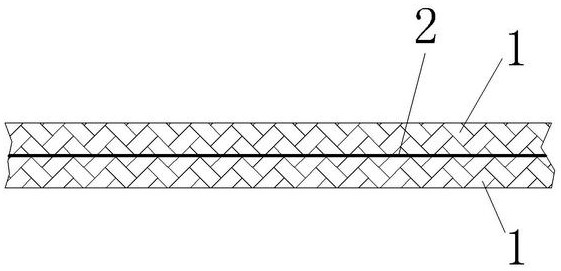

[0009] Such as figure 1 and figure 2 Shown, a kind of ballistic helmet, it is to arrange high-strength titanium alloy wire mesh interlayer 2 in the body 1 of helmet.

[0010] High-strength titanium alloy wire mesh is made of high-strength titanium alloy wire. The advantages of high-strength titanium alloy are high strength, strong bulletproof ability, small specific gravity, and light headwear. The tensile strength of high-strength titanium alloy at room temperature is 1100-1400MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com