body armor

A bulletproof vest and bulletproof layer technology, applied in protective equipment, clothing, clothing, etc., can solve the problem of insufficient bulletproof effect, and achieve the effect of good bulletproof effect, enhanced bulletproof ability, and enhanced absorption and buffering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

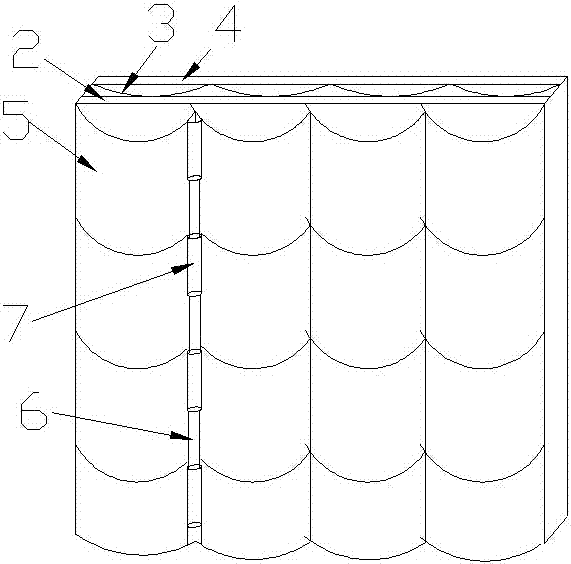

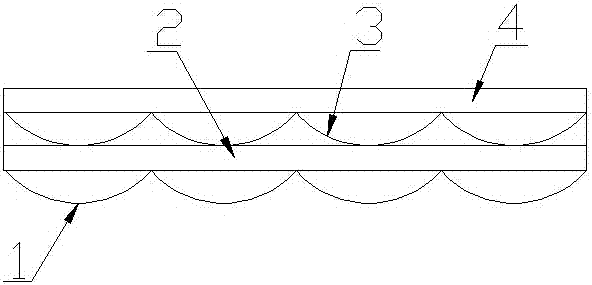

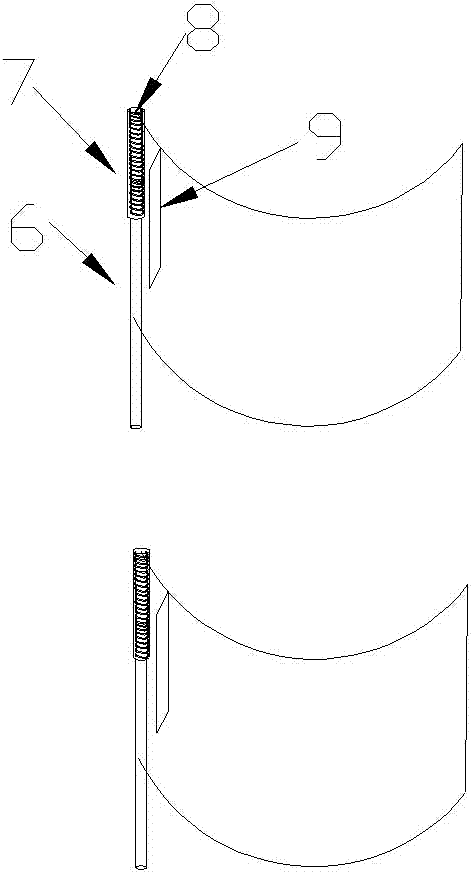

[0014] The alloy aluminum plate and high-strength nylon silk of the BPV-Ⅰ bulletproof vest are made as Figure 1 to Figure 6 , body armor, including two layers of composite bulletproof layers, respectively the first composite bulletproof layer and the second composite bulletproof layer, the first composite bulletproof layer is composed of the first hard bulletproof layer 1 and the first soft bulletproof layer 2, the second The composite bulletproof layer is composed of a second hard bulletproof layer 3 and a second soft bulletproof layer 4. The first hard bulletproof layer 1 is composed of several hard sheets 5 protruding in the direction against the ballistic direction. The second hard bulletproof layer The bullet-proof layer 3 is made of a hard sheet 5 without curvature or a plurality of hard sheets 5 protruding against the ballistic direction. The hard sheet 5 is an alloy aluminum plate. The upper and lower adjacent hard sheets 5 are hingedly connected. One side of each h...

Embodiment 2

[0016] Different from Example 1, the outer tactical vest and the KM-2 Kevlar lining (or needle-punched nonwoven felt) using the "Interceptor" body armor weigh a total of 3.8kg, and two pieces of 1.8kg each are added. The boron carbide ceramic plug-in plate has a total weight of 7.4Kg and a protection level of Ⅳ (refer to the American NIJ standard). Make the structure identical with embodiment 1, as Figure 1 to Figure 6, but the hard sheet 5 is a boron carbide ceramic plate. The first hard bulletproof layer 1 and the second hard bulletproof layer 3 have the same thickness, which is 15mm. The first soft bulletproof layer 2 and the second soft bulletproof layer 4 are made of KM-2 Kevlar or needle-punched nonwoven felt with a thickness of 17mm. With reference to NIJ, the body armor made according to the present invention can defend against 30 caliber armor-piercing bullets (U.S. military M2 AP), with a bullet weight of 10.8g, a minimum bullet speed of 900m / s, and a maximum rear...

Embodiment 3

[0018] Adopting a bulletproof vest that reached level 4 with reference to the GA141-2010 police bulletproof vest standard is raised to level 5 after re-preparing according to the structure of the present invention, which can be lower than the threat of the 56-type 7.62mm semi-automatic rifle. Specifically, two silicon carbide plates of 1.63kg, two layers of needle-punched non-woven felt, each 17mm, and the total weight of the body armor is 5.15kg. According to GA141-2010 test, it can also block the warhead, and the depth of the depression is 5mm smaller than the original 23mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com