Solid waste large-mixing-amount concrete prefabricated laminated slab and preparation method thereof

A concrete and large-volume technology, applied in solid waste management, manufacturing tools, sustainable waste treatment, etc., can solve problems such as the difficulty in erecting laminated slab pipelines, increase the bonding strength of prefabricated layers and laminated layers, and relieve environmental pressure , Improving impermeability, improving the effect of compressive strength in the later stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention has no special requirements for the preparation method of the concrete with a large amount of solid waste, and the above-mentioned components can be uniformly mixed by using a method well known in the art. The present invention uses the concrete described in the above scheme to prepare prefabricated laminated panels, which can promote the multi-scale channel consumption of bulk industrial solid waste, and realize the "dual integration" of prefabricated buildings and solid waste recycling in terms of technology, management and industrial chain. production fusion".

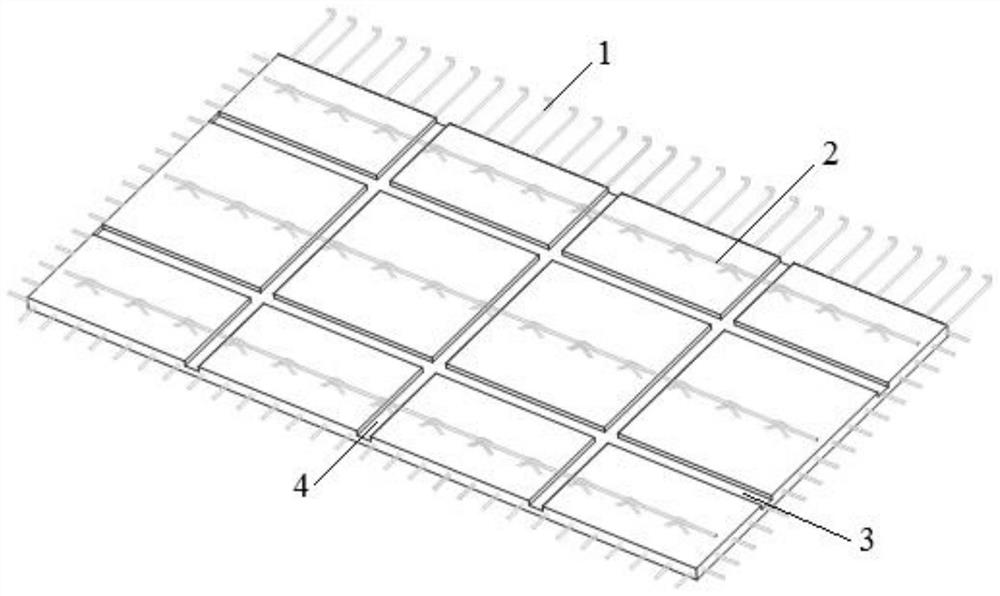

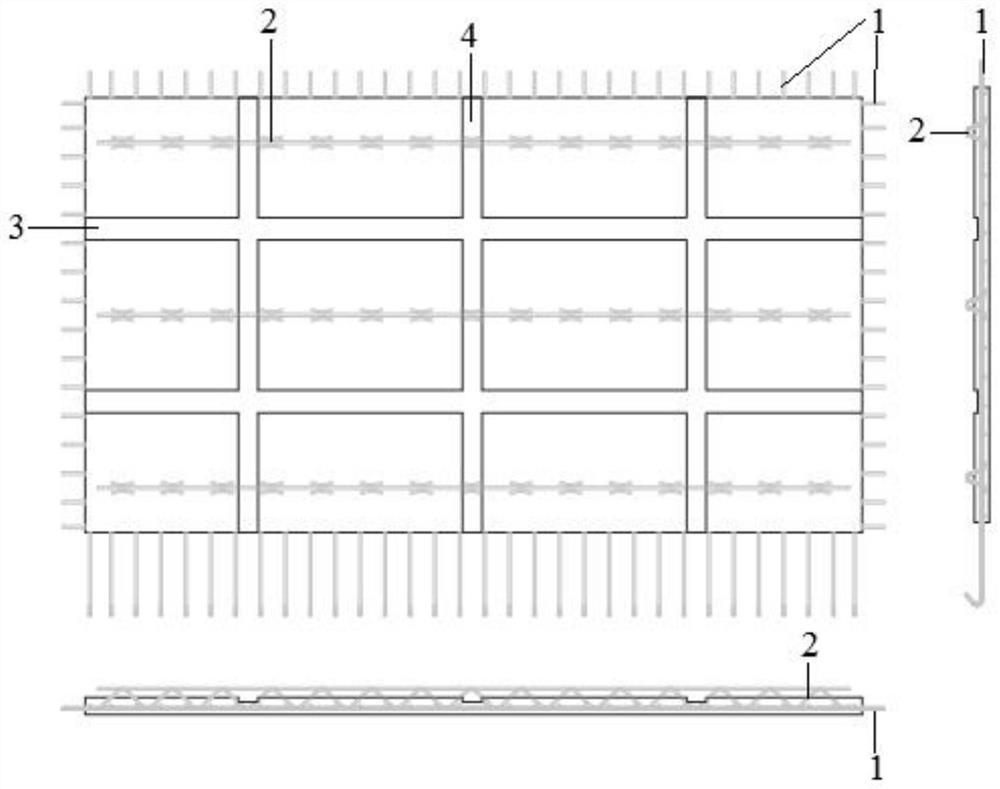

[0037] The prefabricated laminated concrete slab with a large volume of solid waste provided by the present invention includes a prefabricated layer and a laminated layer, and a reinforcement cage is arranged in the prefabricated layer. In the present invention, the surface of one side of the prefabricated layer is provided with several transverse grooves and several longitudinal grooves...

Embodiment 1

[0064] A kind of concrete with a large amount of solid waste, the preparation raw material is: cement 370kg / m 3 , primary fly ash 41kg / m 3 , tailings waste rock 950kg / m 3 , activated iron tailings 20kg / m 3 , tailings fine sand 870kg / m 3 , water 165kg / m 3 , additives (including polycarboxylate water reducer, cellulose ether and dextrin, of which polycarboxylate water reducer 4kg / m 3 , cellulose ether is 0.15% of the quality of polycarboxylate water reducer, dextrin is 1.5% of the quality of polycarboxylate water reducer);

[0065] Among them, the tailings and waste rocks are continuously graded from 5 to 20 mm, the cement is P O42.5 ordinary Portland cement, the fineness modulus of tailings fine sand is 2.1 to 2.2, and the average particle size of activated iron tailings is 10 μm the following.

[0066] The above components were mixed to obtain concrete, and the concrete was naturally cured, and its performance was tested. The results are shown in Table 1:

[0067] Table...

Embodiment 2

[0070] The solid waste large-volume concrete in Example 1 is used to prepare a laminated slab, the laminated slab includes a prefabricated layer and a laminated layer, wherein the thickness of the prefabricated layer is 60 mm, the thickness of the laminated layer is 60 mm, and the surface of the prefabricated layer is provided with transverse grooves and the longitudinal groove, the notch width of the transverse groove and the longitudinal groove is 50mm, the depth is 15mm, the distance between two adjacent transverse grooves is 1 / 3 of the span of the prefabricated layer, and the distance between two adjacent longitudinal grooves 1 / 4 of the span of the prefabricated floors.

[0071] Concrete preparation steps are as follows:

[0072] (1) Clean the template, apply the release agent, and then assemble it according to the size of the laminated board to obtain the mold, brush the interface agent on the surface of the mold, then bind the steel cage, and then install the embedded pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com