Method for preparing large-size micro-groove bionic antifouling coating by template imprinting method

An anti-fouling coating and micro-groove technology, which can be used in coatings, devices for coating liquids on surfaces, and surface pretreatment, etc., can solve problems such as high production costs, harsh process conditions, and complex processes, and achieve low costs. , The effect of low preparation conditions and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

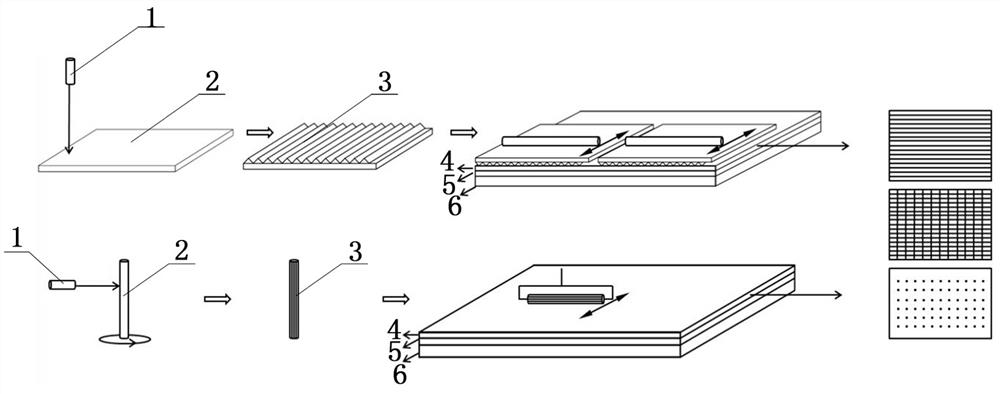

[0045] A method for preparing large-scale micro-groove biomimetic antifouling coatings by template imprinting method. This embodiment is based on a flat template, and specifically includes the following steps:

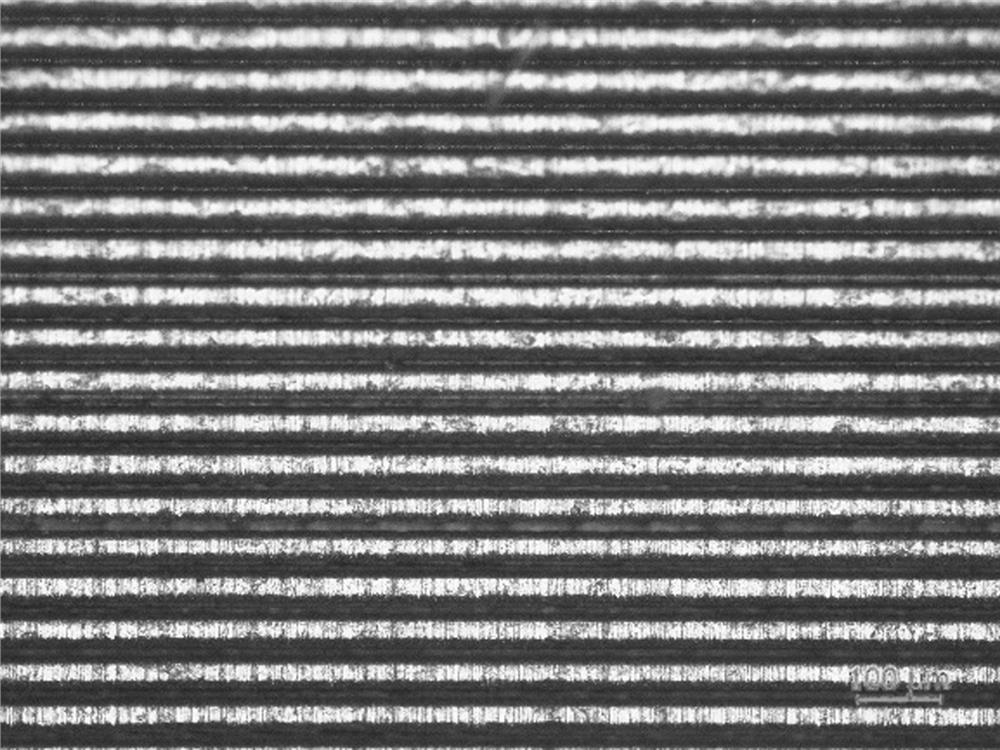

[0046] (1) Using the aluminum alloy material as a template, cut the aluminum alloy material into a rectangle with a length of 200 mm, a width of 100 mm, and a thickness of 1 mm, and then use femtosecond laser micromachining technology to construct a linear groove structure on the aluminum alloy material template , the laser processing process parameters: power 60%, frequency 800KHz, light output width 20μm, continuous light output with two 10mm straight lines (the straight lines coincide, and the processing directions of the two straight lines are opposite during processing), and the platform drives the vibrating mirror at 28mm / s Feed at a high speed, and each single line goes back and forth one by one. After completing a groove processing, continue to emit light with t...

Embodiment 2

[0052] A method for preparing large-scale micro-groove biomimetic antifouling coatings by template imprinting method. This embodiment is based on the roller template, and specifically includes the following steps:

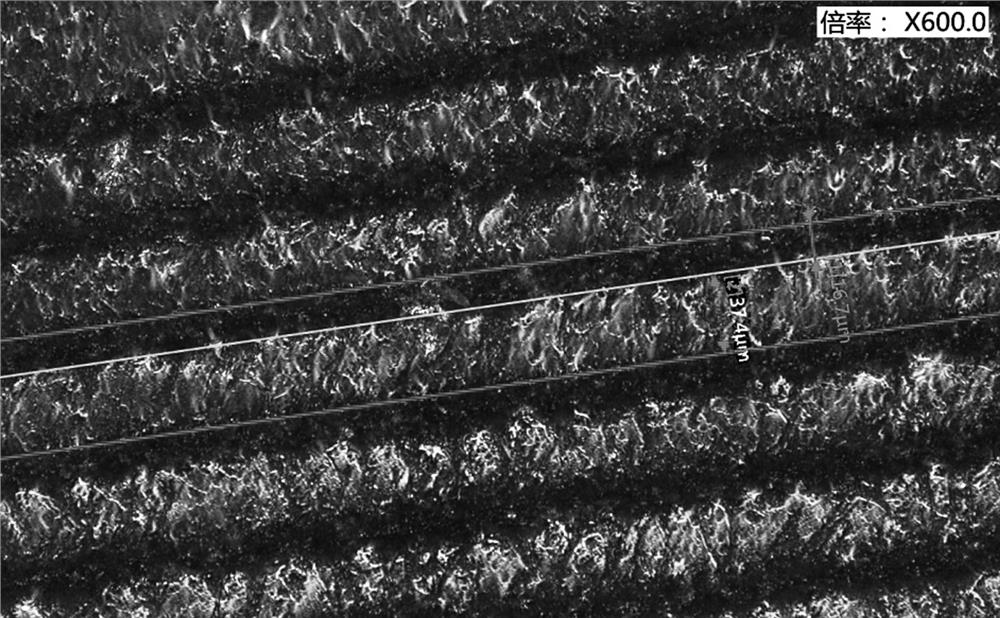

[0053] (1) The stainless steel roller is used as the microstructure template, the length of the roller is 300mm, the diameter is 40mm, the roller is placed vertically and fixed on the rotatable disk, the rotation speed of the disk is set, and then the femtosecond laser micromachining process is used. The laser is perpendicular to the roller template, and a single light source emits light. The laser processing parameters: power 65%, frequency 900KHz, with a single light source radius of 30μm, light is etched every 235μm along the long side of the roller, and each etching is completed 1 Strip dot-shaped groove microstructure, the disc drives the roller to rotate, the rotation distance is 235μm, the disc drives the galvanometer to move to the set position and emits lig...

Embodiment 3

[0058] A method for preparing large-scale micro-groove biomimetic antifouling coatings by template imprinting method. This embodiment is based on a flat template, and specifically includes the following steps:

[0059] (1) Using the silica gel material as a template, cut the silica gel material into a square template with a side length of 500mm and a thickness of 2mm, and then use femtosecond laser micromachining technology to construct a grid-shaped groove structure on the silica gel material template. Processing parameters: power 50%, frequency 600KHz, light output width 40μm, continuous light output with two 10mm straight lines (the straight lines overlap, and the two straight lines are opposite to each other during processing), and the platform drives the vibrating mirror to feed at a speed of 35mm / s. Each single line goes back and forth once, and the horizontal linear groove is prepared first. After the horizontal linear groove is prepared, the longitudinal linear groove i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com