Preparation method of garnet with high power and high dielectric constant and garnet

A high dielectric constant, garnet technology, applied in the field of sound source localization, can solve problems that cannot be separated from process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

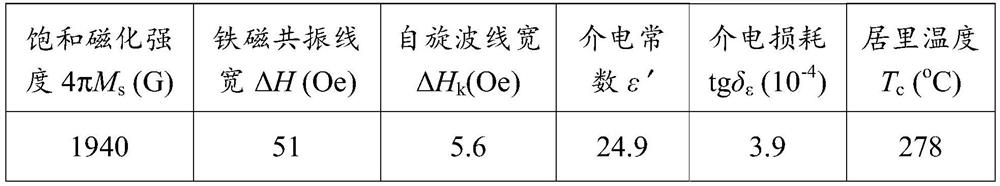

example 1

[0040] (1) According to the chemical formula:

[0041] Y 3-x-z-z′-y-2x′-z″-p-q Bi x SM z Gd z′ Ca 2x′+y+z″+p+q Zr y sn p Ti q Ge z″ In p′ V x′ mn w Al w′ Fe 5-x′-y-z″-p-q-w-w′-δ-p′ o 12 ,

[0042] Take x=1.08, y=0.28, z=0.005, z'=0, z"=0, x'=0, p=0, q=0, w=0, p'=0, w'=0, Calculate the amount of raw materials required separately. Use Sm with purity ≥99.9% 2 o 3 , Y 2 o 3 and analytically pure Bi 2 o 3 , Fe 2 o 3 , CaCO 3 , ZrO 2 , Weigh out the corresponding weight of raw materials. Will Sm 2 o 3 、Gd 2 o 3 , Y 2 o 3 Rare earth oxide raw materials are burned at a temperature of 850°C and cooled in the furnace before use.

[0043] (2) Put the weighed raw materials into a ball mill tank, and add steel balls and deionized water or / and alcohol according to the ratio of material: ball: water = 1:2:1.2, and discharge after 12 hours of ball milling. The ball milling tank is made of stainless steel to reduce the abrasive Fe entering the material during t...

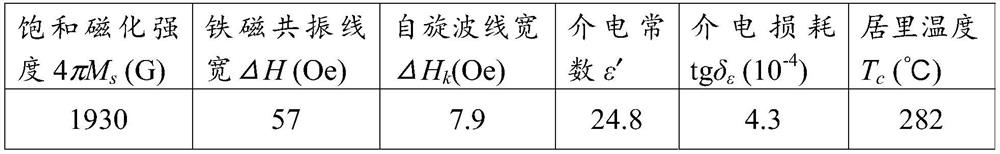

example 2

[0054] (1) According to the chemical formula

[0055] Y 3-x-z-z′-y-2x′-z″-p-q Bi x SM z Gd z′ Ca 2x′+y+z″+p+q Zr y sn p Ti q Ge z″ In p′ V x′ mn w Al w′ Fe 5-x′-y-z″-p-q-w-w′-δ-p′ o 12 ,

[0056] Take: x=1.08, y=0.28, z=0.020, z'=0, z"=0, x'=0, p=0, q=0, w=0, p'=0, w'=0 , respectively calculate the amount of raw materials required. Use Sm with purity ≥99.9% 2 o 3 , Y 2 o 3 and analytically pure Bi 2 o 3 , Fe 2 o 3 , CaCO 3 , ZrO 2 As the raw material, weigh out the corresponding weight of the raw material. Will Sm 2 o 3 、Gd 2 o 3 , Y 2 o 3 etc. Rare earth oxide raw materials are burned at a temperature of 1000°C and cooled in the furnace before use.

[0057] (2) Put the weighed raw materials into a ball mill tank, and add steel balls and deionized water according to the ratio of material: ball: water = 1: 3.5: 1, and discharge after a ball mill for 18 hours. The ball milling tank is made of stainless steel to reduce the abrasive Fe entering the...

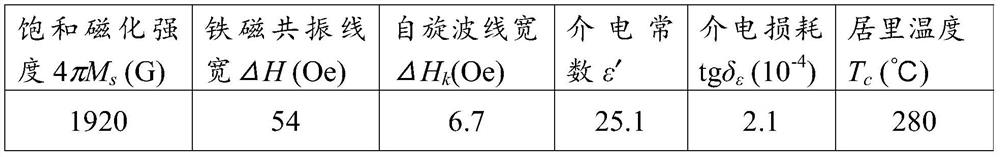

example 3

[0068] (1) According to the chemical formula

[0069] Y 3-x-z-z′-y-2x′-z″-p-q Bi x SM z Gd z′ Ca 2x′+y+z″+p+q Zr y sn p Ti q Ge z″ In p′ V x′ mn w Al w′ Fe 5-x′-y-z″-p-q-w-w′-δ-p′ o 12 ,

[0070] Take: x=1.06, y=0.30, z=0.01, z'=0, z"=0, x'=0, p=0, q=0, w=0, p'=0, w'=0 , respectively calculate the amount of raw materials required. Use Sm with purity ≥99.9% 2 o 3 , Y 2 o 3 and analytically pure Bi 2 o 3 , Fe 2 o 3 , CaCO 3 , ZrO 2 As the raw material, weigh out the corresponding weight of the raw material. Will Sm 2 o 3 、Gd 2 o 3 , Y 2 o 3 Rare earth oxide raw materials are burned at a temperature of 1200°C and cooled in the furnace before use.

[0071] (2) Put the weighed raw materials into the ball mill tank, and add steel balls and deionized water according to the ratio of material: ball: water = 1: 5: 0.7, and discharge after 24 hours of ball milling once. The ball milling tank is made of stainless steel to reduce the abrasive Fe entering th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com