Geopolymer with high carbonation resistance and its preparation method

A technology of geopolymer and carbonization, which is applied in the field of high carbonation resistance geopolymer and its preparation, can solve the problems of affecting the durability of alkali-induced concrete, the decrease of concrete pH value, and the destruction of steel protective film, so as to be easy to popularize and use , Eliminate foaming and expansion when encountering alkali, and reduce project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

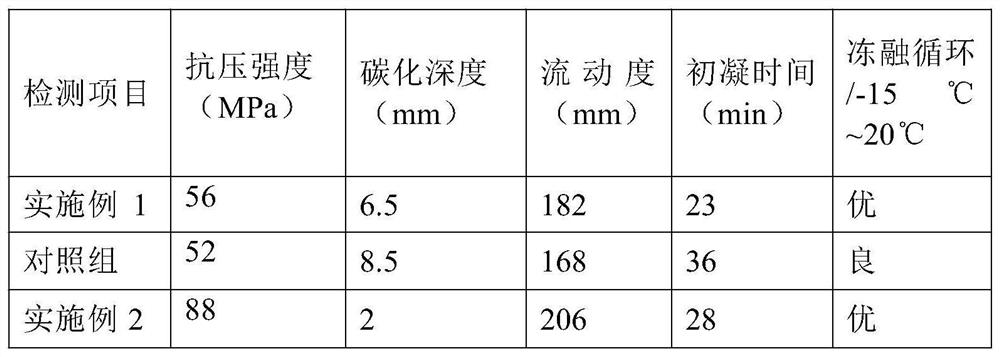

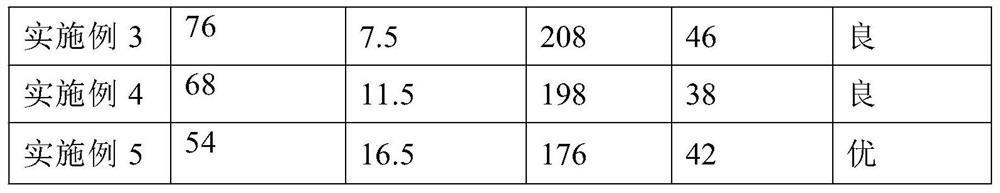

Examples

Embodiment 1

[0029] The preparation process of the highly carbonation-resistant polymer in this example is as follows:

[0030] Put 0.09 parts of modified multi-walled carbon nanotubes and 0.07 parts of dispersing agent in 4 parts of water, stir for 240s, and then put them under the power of 400W for 0.5 hours to obtain a uniform mixed solution of 4.16 parts, then weigh 27 parts Portland cement, 1 part of calcined metakaolin, 3 parts of silica fume, 1 part of modified red mud, 15 parts of quartz sand, poured into a mixer and stirred for 150s to obtain the mixture particle A, and then weighed 40 parts of modified city Bottom ash from solid waste combustion, 4 parts of solid sodium hydroxide and 5 parts of sodium silicate powder were added to a muffle furnace (set temperature at 700°C) for calcination for 1 hour, cooled and sieved to obtain geopolymer mixture B, Add mixture A and mixture B into the mixing pot and stir for 120s, then add 4.16 parts of the mixed solution obtained in the above ...

Embodiment 2

[0032] The preparation process of the highly carbonation-resistant polymer in this example is as follows:

[0033] Put 0.08 parts of modified multi-walled carbon nanotubes and 0.08 parts of dispersant in 4 parts of water, stir for 240s, and then put it under the power of 400W for 0.5 hours to obtain a uniform mixed solution, then weigh 23 parts of silicic acid Salt cement, 1 part of calcined metakaolin, 3 parts of silica fume, 1 part of modified red mud, and 15 parts of quartz sand were poured into a mixer and stirred for 150 seconds to obtain mixture particle A, and then 44 parts of modified municipal solid waste weighed Burn the bottom ash, add 4 parts of solid sodium hydroxide and 5 parts of sodium silicate powder into a muffle furnace (set temperature at 750°C) for calcination for 2 hours, cool and sieve to obtain geopolymer mixture B, mix Add material A and mixture B into the mixing pot and stir for 120s, then add 4.16 parts of the mixed solution obtained in the above ste...

Embodiment 3

[0036] The preparation process of the highly carbonation-resistant polymer in this example is as follows:

[0037]Put 0.09 parts of modified multi-walled carbon nanotubes and 0.08 parts of dispersing agent in 4 parts of water, stir for 300s, and then put them under the power of 400W for 0.6 hours to obtain a uniform mixed solution of 4.17 parts, then weigh 23 parts Portland cement, 1 part of calcined metakaolin, 3 parts of silica fume, 1 part of modified red mud, 15 parts of quartz sand, poured into a mixer and stirred for 150s to obtain the mixture particle A, and then weighed 44 parts of modified city Bottom ash from solid waste combustion, 4 parts of solid sodium hydroxide and 5 parts of sodium silicate powder were added to a muffle furnace (set temperature at 800°C) for calcination for 2 hours, cooled and sieved to obtain geopolymer mixture B, Add mixture A and mixture B into the mixing pot and stir for 120s, then add 4.17 parts of the mixed solution obtained in the above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com