Ultra-high tenacity multi-walled carbon nanotube-polyvinyl alcohol fiber modified geopolymer and preparation method thereof

A multi-wall carbon nanotube and polyvinyl alcohol fiber technology is applied in the field of ultra-high toughness multi-wall carbon nanotube-polyvinyl alcohol fiber modified geopolymer and its preparation, which can solve the problems of low toughness and low tensile strength, etc. problem, to achieve the effect of fast setting time, simple preparation method and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

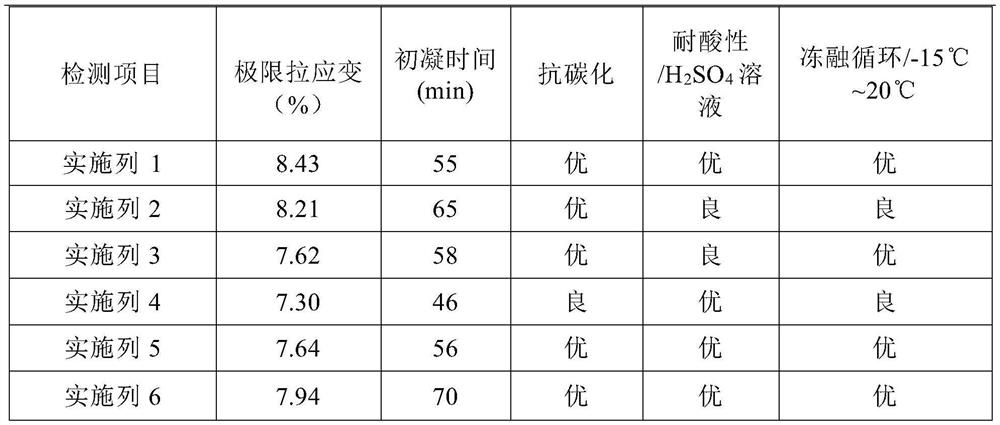

Examples

Embodiment 1

[0028] In the present embodiment, 28 parts of fly ash, 8 parts of slag, 2 parts of metakaolin, 2 parts of silica fume, and 37 parts of quartz sand are poured into the mixer, stirred at a slow speed for 100 seconds to obtain a mixture, and then 0.03 1 part of dispersant, 0.04 part of defoamer and 7 parts of water are placed in 15 parts of complex base excitation solution, stirred for 180s, and then placed under 300W power for 0.5 hours to obtain a uniform mixed solution, and then this uniform mixed solution is added Stir in the above mixture for 150 seconds, then add modified multi-walled carbon nanotube-polyvinyl alcohol fibers, stir slowly for 60s, stir quickly for 90s, then pour, vibrate, and maintain for 28 days under standard curing conditions to obtain The super high tenacity multi-walled carbon nanotube-polyvinyl alcohol fiber modified geopolymer.

Embodiment 2

[0030] In the present embodiment, 27 parts of fly ash, 9 parts of slag, 3 parts of metakaolin, 1 part of silica fume, and 38 parts of quartz sand are poured into the mixer, stirred at a slow speed for 100 seconds to obtain a mixture, and then 0.03 1 part of dispersant, 0.04 part of defoamer and 7 parts of water are placed in 15 parts of complex base excitation solution, stirred for 210s, then placed under 400W power for 0.6 hours to obtain a uniform mixed solution, and then this uniform mixed solution is added Stir in the above mixture for 165 seconds, then add the modified multi-walled carbon nanotube-polyvinyl alcohol fiber, stir slowly for 75s, stir quickly for 105s, then pour, vibrate, and maintain for 28 days under standard curing conditions to obtain The super high tenacity multi-walled carbon nanotube-polyvinyl alcohol fiber modified geopolymer.

Embodiment 3

[0032] In the present embodiment, 25 parts of fly ash, 9 parts of slag, 3 parts of metakaolin, 3 parts of silica fume and 37 parts of quartz sand are poured into the mixer, stirred at a slow speed for 100 seconds to obtain the mixture, and then 0.04 1 part of dispersant, 0.02 part of antifoaming agent and 7 parts of water are placed in 15 parts of complex base excitation solution, stirred for 240s, then placed under 500W power for 0.5-0.7 hours to obtain a uniform mixed solution, and then the uniform mixed solution Add the solution to the above mixture and stir for 180 seconds, then add the modified multi-walled carbon nanotube-polyvinyl alcohol fiber, stir slowly for 90s, stir quickly for 90-120s, then pour, vibrate, and maintain under standard curing conditions The superhigh toughness multi-walled carbon nanotube-polyvinyl alcohol fiber modified geopolymer was obtained in 28 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com